Everything posted by Great work!

-

DIY vp 44 and ECM. It runs, very happy

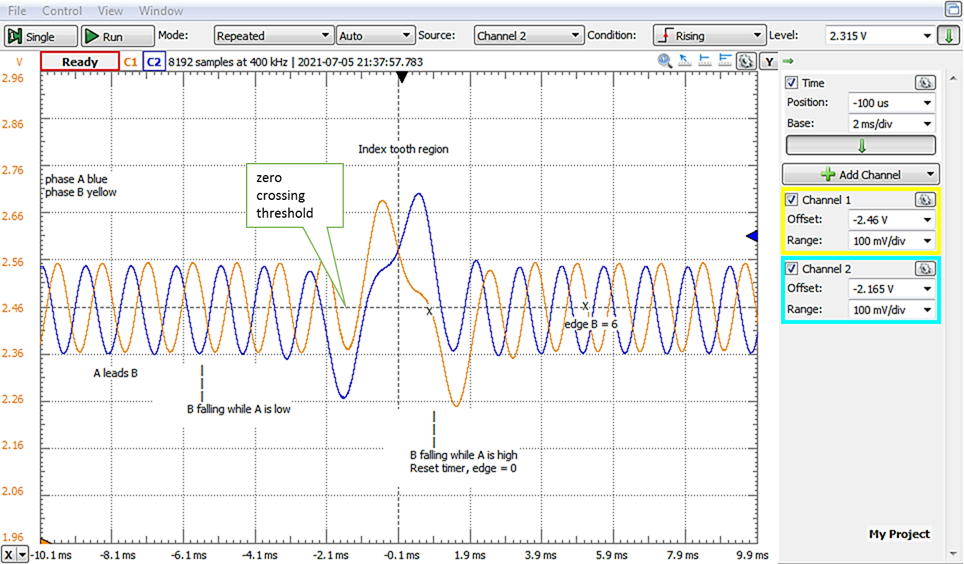

This diagram shows the 2 signals that the speed sensor in the VP produces. The tone wheel on the pump shaft has 6 index regions spaced every 60 degrees. The index teeth have 2 wider then normal teeth with a deeper cut between them. In the diagram notice there is a unique alignment where the B phase is falling below the zero cross dashed line and the A phase is above the line. When the software detects this condition it resets a timer and edge counters. The injection starts at edge 19. By measuring the time between tooth edges, velocity and acceleration can be calculated. Then applying kinematic equations we can predict edge 19 before it happens. We have to do this because the injection solenoid has deadtime so it has to be energized some time before the injection event is to occur.

-

1999 No Start No codes

Every thing seems ok

-

1999 No Start No codes

Seems right but the buses on the '-' side should not be hard grounds they should have some resistance to ground. Do you get a wait to start blink?

-

1999 No Start No codes

Correct and ground of course.

-

1999 No Start No codes

I hope you're not fighting a security related issue some trucks had extra theft detection stuff. Wasn't as common in 99. Make sure the cummins bus / can bus connection hasn't been hacked up by some tuner too. Need power to red white wires at ecm and green black wire with key on.

-

DIY vp 44 and ECM. It runs, very happy

I would say the 800 rpm idle was chosen because it has less vibration and buzz sent to the truck. I tried it at 600 and the buzz from the motor was bad

-

Fel Pro head gasket gave up in 4k miles

Those blue fel pro gaskets are pretty good, I wonder what happened. I spray copper permeatex around the edge and then clean any off the main metal sealing rings.

-

Angry & can't do it anymore, serious iQuad timing issues

That looks ok.

-

Angry & can't do it anymore, serious iQuad timing issues

Make sure the valve stem is higher then the spring retainers and that the tappers are not worn down. the tappers should never make contact with the retainer only the stem.

-

Does the VP44 completely shut off fueling when truck is coasting in gear on a downgrade (manual transmission)?

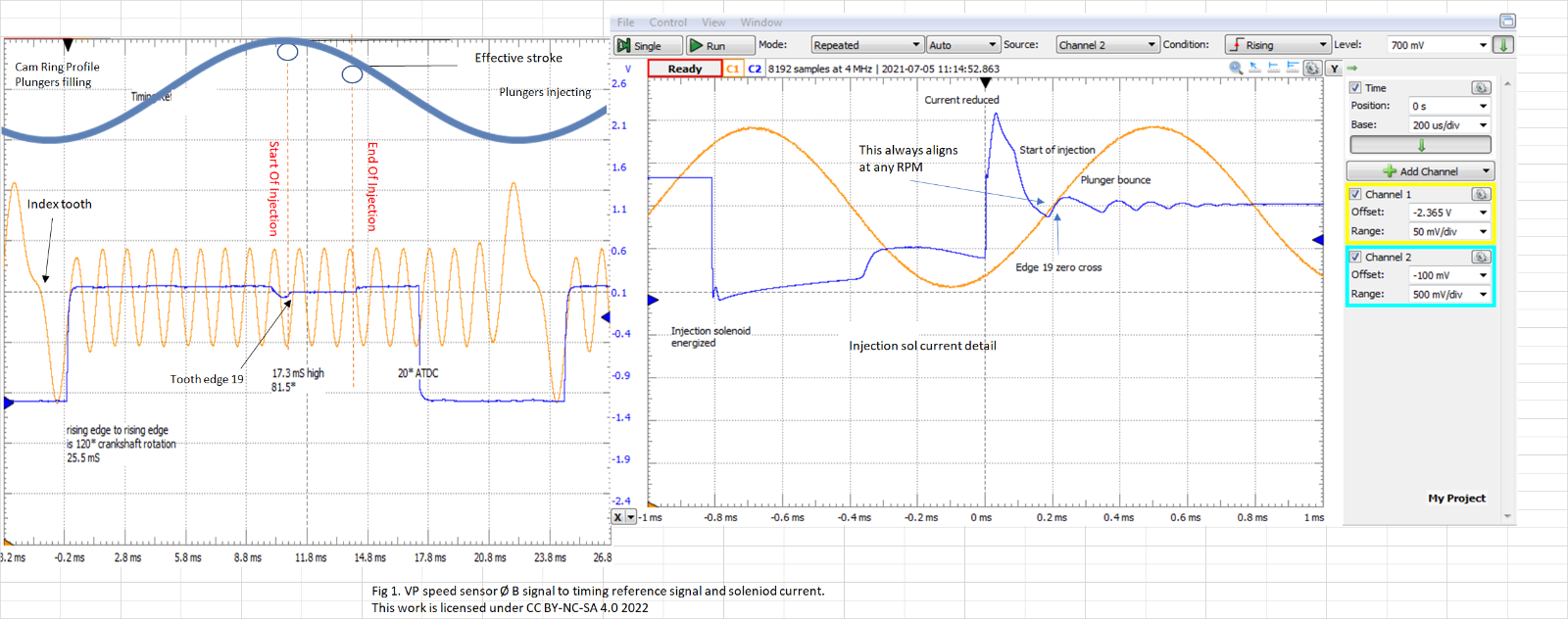

I can confirm the fuel cuts to zero when coasting and even when quickly revving in neutral and instantly letting off. The 0 to 4095 is not milliseconds it is degrees scaled, basically every 512 of 4096 is roughly 6 degrees (crank) of injection. At 1000 rpm 1 millisecond is 6 degrees. At 3000 rpm 1 millisecond is 18 degrees. However fuel delivery in ml or cc is not linear 0 thru 4095 because of the cam shape. the first few degrees and the last few degrees are moving the plungers very little. The bulk of injection is in the middle of the the cam lift. Just like valve lift specs there is advertised duration and at .050 the valve is flowing very little under .050 lift. That's why you can see the injection as high as 12 to 15 degrees just to idle the engine . the first 5 degrees or so is doing almost nothing. However doubling that 15 to 30 degrees is injecting a lot more than double the fuel in ml or cc.

-

DIY vp 44 and ECM. It runs, very happy

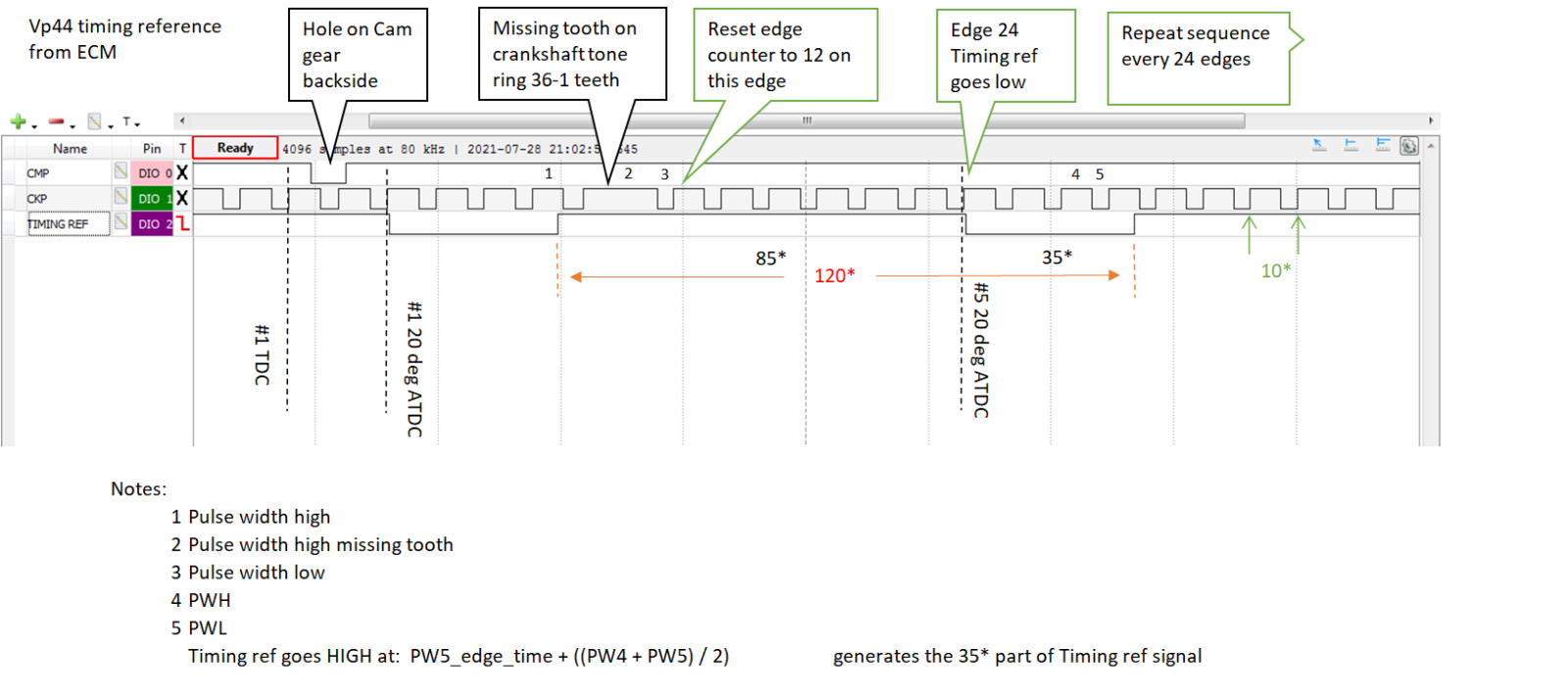

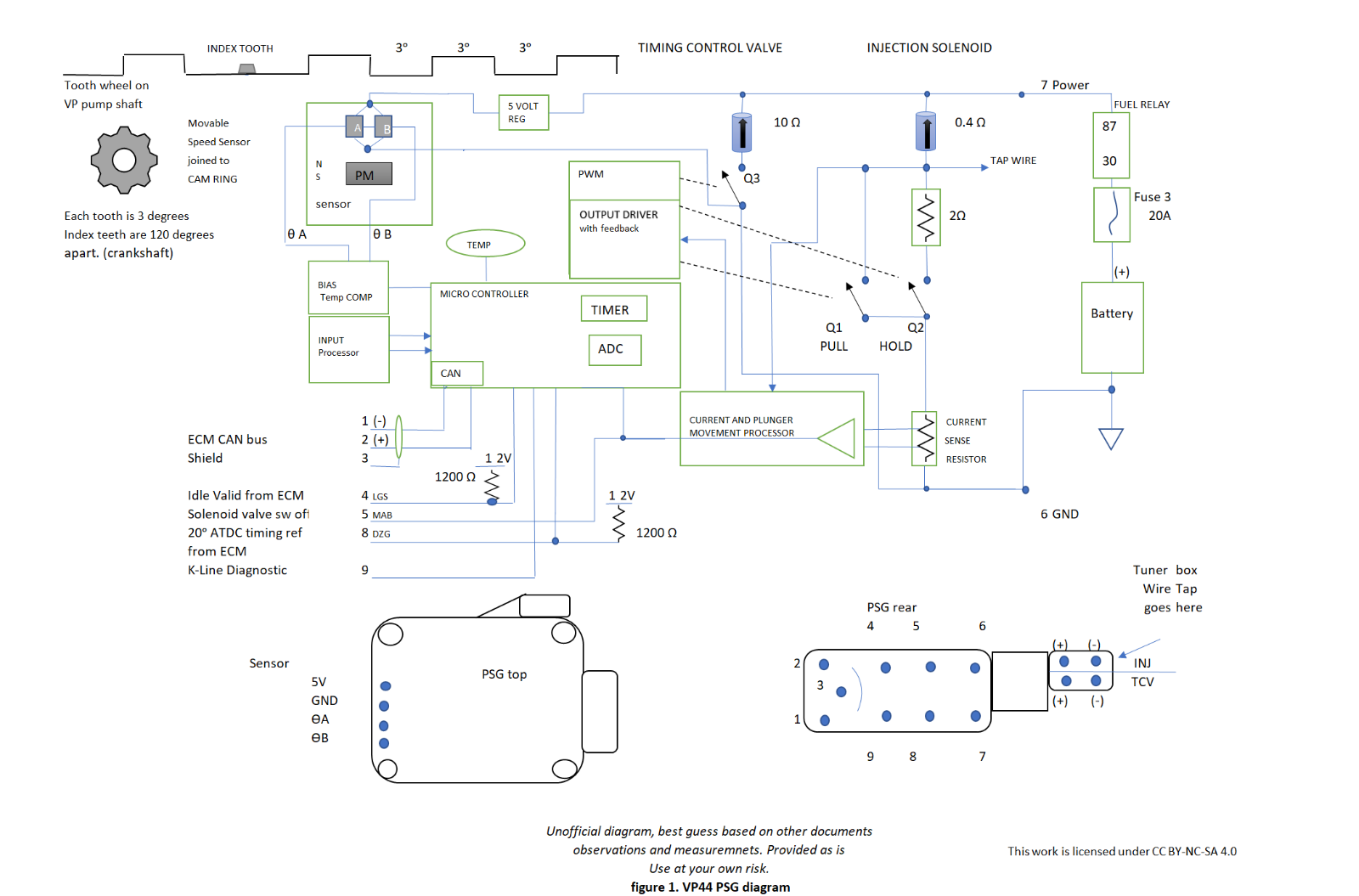

The fish are biting and work is busy so the truck is on the back burner again and fuel costs so much. In extreme cold you only have 2 maybe three tries to start. once the battery voltage falls off the VP simply won't inject. I should have done this 20 years ago. Could have made some money. But I could have never afforded a new truck to hack up and lose the warranty. This diagram shows how the crankshaft and camshaft sensors on the early engines are decoded to provide a signal whose falling edge is at 20 degrees after top dead center. The pump uses this reference signal to determine the relationship of its internal sensor, which is attached to the cam ring to the engine position. That's how it calculates timing this value is compared to CAN command timing and the amount of error feeds a servo control loop which changes the duty cycle of the timing control valve which either fills or vents the the timing piston causing it to move against a return spring. If the error is to great for over a certain amount of time P0216 gets thrown. I have a new Tiny Tach with a piezo line clamp on the injection line. I only bought it for the piezo clamp so I can connect it to my oscilloscope and see when the injector starts spraying. That should be interesting. I think the ECU has a line delay stored inside to really get things dead on. This all seems like overkill considering the P7100 does none of this.

-

White smoke, low power when starting

Your white smoke and power lose could be sticky VP timing piston that would be odd on a newer IP. Keep an eye out for 216 dtc code. Check for clogged fuel filter. Clean up battery terminals. And consider the WT-mod.

-

Angry & can't do it anymore, serious iQuad timing issues

Any air in fuel line? Use a clear hose between the filter and pump look for foam. Could be some clutch rattle. Loose exhaust bolts or turbo bolts can make weird sounds too. You can usually go a little tighter on valve lash on a broke in motor, just need to have some jiggle room when warm.

-

Fuel pressure issue, works but doesn't.

Next time when the pump should be running but is not, slide under and wiggle wires where they enter or terminate at the pump see if it's intermittent there.

-

Squirrels Got Me Good

I have some kittens someone dumped they are eating lots of critters now even a mole. I keep them slightly hungry so they learn to hunt.

-

DIY vp 44 and ECM. It runs, very happy

So I needed to make the connections on the vp44 more permanent now that I proved it works. I also wasn't sure how much the psg interacts with the internal sensor as far as temperature compensation and bias so I took out the sensor and isolated and did some testing and found it to be quite stable on its own. I modified a defective psg to access the sensor connector and soldered on an old jet ski plug to connect to my project. I almost goofed big time, I put some aluminum foil in the pump so I would not drop the screws in it (still on the motor) and left the foil in there. Had to take the cover off again when I realized it. Thank you. It's been a big project and a lot of things have been neglected around the house I hope the neighbors don't mind

-

Fel Pro head gasket gave up in 4k miles

Curious what kind of antifreeze were you using?

-

DIY vp 44 and ECM. It runs, very happy

Started right up this morning 40F no grid heaters. Timing at about 4* at 200 rpm to 400 then 9* and 16* cold idle. Almost no smoke. Surged a couple times on first start then soothed out. It likes 10 - 11 warm idle gets rid of some of the rattle. I set the injection duration to 21* for starting plus I can add more manually with the pedal, it takes about 12* of fuel just to idle. It may need more fuel for extreme cold starts.

-

Angry & can't do it anymore, serious iQuad timing issues

Maybe the Quadzilla should take over all RPM and be the idle governor instead of the ecu it would have to fudge some of the reply messages from VP to ECU to keep it happy. IDK that could be pretty tricky.

-

Quad Cab door won't open

I have mixed feelings about lube, it attracts dirt and gets old and gummy then the latches have problems. On the other hand no lube causes rust.

-

DIY vp 44 and ECM. It runs, very happy

Here are some diagrams I put together that shows how the Vp sensor and solenoid drive current look. There is also the timing ref signal that used to come from the ECM. The vp sensor has two Hall or magneto resistive cells spaced about 1 millimeter apart. I call the signal from the leading cell phase A and the lagging signal phase B. The index tooth causes the A and B to momentarily shift polarity relationship when that occurs I call that tooth edge zero and start a timer at 0 microseconds. At tooth edge 19 the cam rollers go from expanding to compression, that is the cam apex, The inj fuel valve must be closing at that instant, not much before or after that moment.

-

DIY vp 44 and ECM. It runs, very happy

I got the TPS noise settled down. The micro controller I'm using can do analog to digital conversions with no CPU load so instead of supervising the sampling which slows things down, I just let it go randomly and ignore all the samples except the good ones when there is less electrical noise which is before the injection event. That helped a lot. Then I average the samples some too.

-

Quad Cab door won't open

Passengers side would not open latch at bottom hopelessly rusted solid. I had to very carefully use a cutting torch inside the door to burn the latch into pieces and then weld up the now big holes and re drill new holes for a new latch.

-

DIY vp 44 and ECM. It runs, very happy

I had some time to work on the truck tonight. Got the timing readings smoothed out and worked on the predictor algorithm some and got it running even smoother. I found it to be more tolerant in real world then in the lab I guess I was to picky. Next is cold starts I need that done before the weather gets any warmer. It likes to idle at about 10 BTDC warmed up but wants much more cold to clear up the exhaust. I need to drop it to about 5 deg for cranking in extreme cold. Then jump to 15 or more while warming up.

-

DIY vp 44 and ECM. It runs, very happy

4000 crank. The sol plunger has mass and inertia so moving it (faithfully) at high speed requires a lot of electricity which makes for a very hot solenoid. 4000rpm = 200 hz or strokes per second for the plunger granted it moves slightly less then a millimeter it takes a lot. That's the drawback of rotary pumps.