Everything posted by Texas CTD

-

No name

If you have a fastener hand tight, and you set you're torque wrench to 125 ft/lbs, and you sweep up til it clicks in one motion, with proper lube and a properly calibrated torque wrench, you're at 125 ft/lbs. If you have a fastener torqued to 125 ft/lbs, and you want to "re-torque" the way of the interwebz, you set your torque wrench to 125 ft/lbs and click it. Unless a fastener has lost considerable pre-load due to heat/cool cycles, it won't move, and your torque wrench will click... It takes more than 125 ft/lbs of torque to get that already tight fastener moving, due to static friction, so actual pre-load on that fastener is lower than what your wrench just told you. By removing the nut and washer to re-torque a head stud, you lose the static friction, and lube the snot out of it to minimize kinetic friction during the re-torque to be as accurate as possible. May not be the best scientific explanation, but that's what I have experienced messing around with torque wrenches a little. Jacob might say otherwise. lol

-

No name

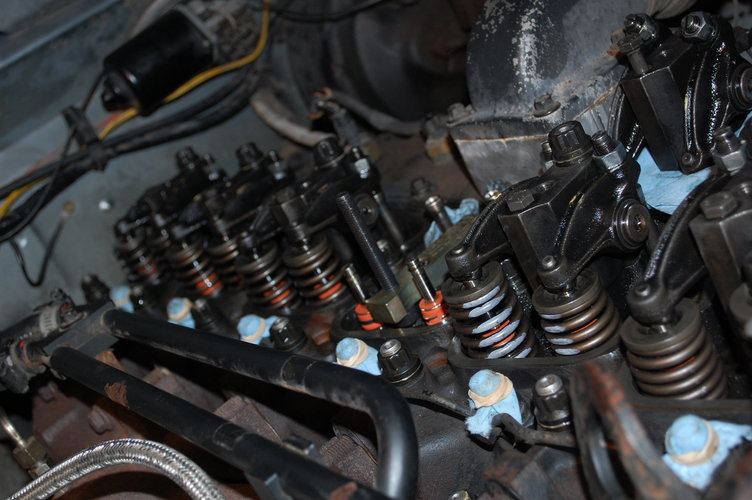

I'm don't want to rain on Jacob's parade or cause conflict by posting another opinion, but I'm sure he'd be fine with the procedure I'm about to post as well. This is from Josh (jmd025) on Cummins Forum... I'm currently in the middle of this procedure on my 12V. ""Assuming a new gasket: Verify head and deck flatness and straightness are within spec clean sealing surfaces with razor Using WD40 and Wet sanding paper , and a sanding block the width of the head/deck start at 100 grit very lightly, then 600 grit, then 1500 grit polishing both sealing surfaces evenly Clean up sealing surfaces and mess from wetsanding. (obviously oil and water in the block with need flushing) Also blow clean all stud holes. Ill try to only use the New Cummins gaskets with the additional reinforcement tabs and set the gasket and head very gently with a engine lift to avoid any shearing movements between the head and gasket. Install head studs. there is a lot of ideas about bottom tapping, and screwing the stud back up a partial turn from the bottom of the hole, i personally just didnt let the stud bottom out. ARP lube top threads. ARP lube washer flats, APR lube Nut flats. Torque in Cummins pattern in equal steps up to your final torque, taking a break between each torque step to allow studs to cool back to room temp (if you've never done this, they get hot while torquing them down). Once final torque is achieved (hopefully manufacturer specs, there is really nothing to gain IMO by exceeding them, in some cases it is actually detrimental to clamping force due to stretching the fasterner outside of its working range), button everything up and fill block with water ( i fill through a heater hose held as high as possible ) and Plug in block heater over night. Disconnect the Block heater in the morning and let the engine go back to stone cold. One at a time , in Cummins sequence, loosen a nut/washer off a stud, RELUBE, and torque back up to final torque in one smooth sweep. Continue until all 26 are retorqued. Plug in block heater over night. Disconnect block heater in the morning and let engine go back to stone cold. One at a time , in Cummins sequence, loosen a nut/washer off a stud, RELUBE, and torque back up to final torque in one smooth sweep. Continue until all 26 are retorqued. change the fluids and drive the truck. Hopefully if you do this you understand how to use a torque wrench and hopefully understand what fasterner "break away " torque is, and why you cant set your torque wrench to 125 ft lbs and "check to see if they are still torqued" by clicking the wrench on the nut. Hopefully Just my .02 , gathered from convos with engine builders i trust"" ^^^^ I bookmarked that 4 years ago, and thought to myself, "I'm gonna need that one day." And sure enough...

-

No name

Do you use the ARP lube for torquing? Is there a substitute for it? Finally got my head back from the machine shop, (they took their sweet time, and lost some of my parts) and I'm ready to go back together with it this weekend, but I realized I didn't have any ARP lube. Can't find it locally, and I ordered a bottle online, but it's saying it won't be here til next week...

-

MoparMan's Hx35/40

http://lmgtfy.com/?q=SAC+vs+VCO Yeah, I had to do it.

-

how do I identify my stock turbo?

I'm sure you're correct, but I'll double check... I got a '95 and a '98.5 sitting at the house.

-

how do I identify my stock turbo?

'95-'00 automatic and manual trucks had the HX35W. '01-'02 Manual (5 and 6 speed) trucks had the same turbo. (HX35W) '01-'02 Automatic trucks got the HY35 for whatever reason. Somewhere along '99-'00, the HX35's went from a 6 blade compressor wheel to a 7 blade wheel.

-

No name

How much did it cost you to machine the pedestals? I asked 2 shops today about doing them. One shop wouldn't do it, the other said it would be $40 each... Screw that.

-

No name

Brake clean.

-

No name

That two-tone sport is just sexy. Glad she's finally getting some fuel and air.

-

Head bolts

Stock bolts. And I agree, don't touch them. Re-torque on a torque-to-yield bolt = snap! (most of the time not, but it would if I tried it)

-

Bought Me a First Gen

It does, for what it is. If my speedo worked, it would wrap around pretty fast. GPS doesn't respond fast enough to look cool. It would be really fun with a 47RH, but that's another problem for another time.

-

Bought Me a First Gen

Geez, no updates in forever. I guess there's not a whole lot to update though. I did get the S362 rebuilt under warranty, and it has been fine. In December I dyno'd the truck. Best numbers were 434HP / 901TQ. https://www.youtube.com/watch?v=ukJJ43plgIU Other than regular maintenance, and a water pump, I haven't done anything to it. Been working 70-75 hours a week, so that doesn't leave much time for truck shenanigans.

-

Harvey

Well Houston has gotten record flooding once again. To the southwest they've had major damage from the Cat 4 hurricane last weekend. It's stalled out as a tropical storm, and supposed to keep dumping rain for the rest of the week. I live 50 miles north of Houston, and we've got about 14"-15" inches of rain in 48 hours. Creeks are out of their bank, and we got the cows closed off in the high pasture. I know forum member, "The_Hammer" has posted before about getting flooded out, and wouldn't doubt if he's flooded again. He's from the Wharton area, which is southwest of Houston.

-

Mopar73 Full Eclipse Meet and Greet Camp Trip Aug 18th Thru the 21st 2017

VP44 causes of death: -lack of fuel pressure -lack of lubrication -lack of filtration -AC noise -Solar Eclipses??? Sorry to hear about the breakdown, but really couldn't have happened at a better time.

-

Mopar73 Full Eclipse Meet and Greet Camp Trip Aug 18th Thru the 21st 2017

"The Heavens declare the glory of God, and the sky proclaims his handiwork." -Psalm 19:1. Hope y'all have a good time. I'll try to catch a glimpse of it down here, but the above verse comes to mind.

-

Bought Me a First Gen

Update as of Sunday... https://www.youtube.com/watch?v=JkYpWc2CzCw Seals failed on exhaust and intake sides. Pumped the charge pipes and intercooler full of oil, but luckily it didn't get past the intercooler. Slapped the HX35 back on, and dang if those seals hadn't gone too. I guess from sitting dry for 4 months? Sent the S362 out to be warrantied, and ordered a rebuild kit for the HX35. Hoping to be back on the road by the weekend. Debating on compounds, or run the 62 a while longer after it gets warrantied.

-

Airbox

1st gen guys do it. Never really heard of 2nd gen guys do it.

-

Truck died in deep water

Any codes? Maybe remove the ECM and let it dry out more thoroughly? (if that's even the problem)

-

Bought Me a First Gen

A couple clips my buddy shot:

-

Bought Me a First Gen

Exhaust change up...

-

Bought Me a First Gen

No major updates... Last weekend I took a 400 mile round trip to pick up an all-aluminum powerstroke intercooler. Drove 65-70 MPH, and got 20.8 MPG. So far Ive given people rides, and raced one 2nd gen... Everybody is pretty impressed with the power in this old farm truck.

-

P0216 - Sad but true...

P-Pump!!! I had to. Hope she's back on the road ASAP, Mike, and the next one lasts 1/4 million miles.

-

Bought Me a First Gen

It should sound nastier with more timing. I love that deep growl. As it sits, it starts building boost at 1,600 RPM, and by 1,700 it's ready to takeoff. And even though it's making boost, it's 2,000 RPM before I'm cleaning up smoke, and even then it hazes under heavy throttle. That's mostly due to the power screw being in as far as it can safely go. (which controls duration, so yeah, it's going to be dirty with lots of duration in my setup) Like I said, lots of pump tuning still to do. I'm happy with the power, I'm just trying to get it to run cleaner. After it's all dialed in, I'll hit the dyno. Goal is 400/800, but would like to get closer to the 450 HP mark. (which is hard to do with a VE truck)

-

Bought Me a First Gen

I've had no time to work on this thing. Still lots of pump tuning and timing to adjust. Here's a 45-85 MPH roll-on. http://www.youtube.com/watch?v=p87DXokqnVc

-

Bought Me a First Gen

Thanks, it's getting there. Still need to paint more parts, and clean up wiring. 62/68/.70 SX-E