- Replies 12

- Views 4.6k

- Created

- Last Reply

Top Posters In This Topic

-

Sycostang67 3 posts

-

Silverwolf2691 3 posts

-

Tractorman 2 posts

-

Stanley 2 posts

Most Popular Posts

-

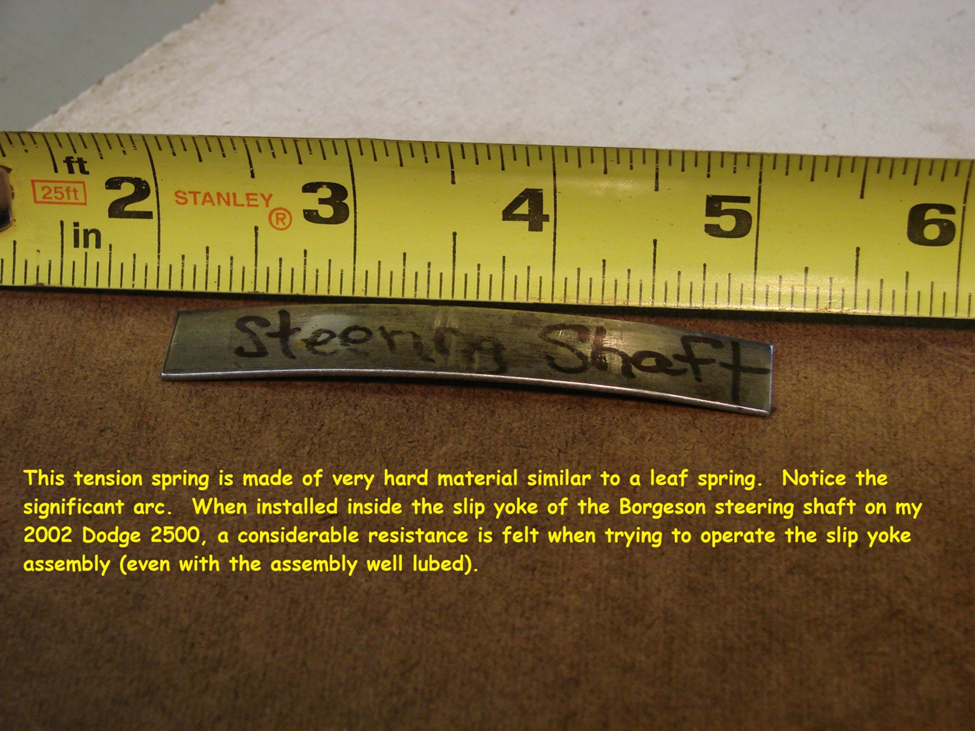

Even keeping it lubed did not help me. I have had the Borgeson steering shaft for about 150,000 miles now. The first thirty thousand miles almost drove me nuts. It took 30,000 miles of driving to f

I replaced my steering shaft a couple years ago with a Dorman part. The truck was my daily at the time and I needed it back on the road right away. While I have little faith in Dorman would upgrading to Borgeson shaft improve my steering feel any? I already have a Red head box and HD 3rd gen T-style steering. I still have a little play left in the steering which I'm wondering if it's caused by the cheap shaft twisting.