- Replies 65

- Views 5.4k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 36 posts

Mopar1973Man 36 posts -

Tractorman 13 posts

Tractorman 13 posts -

Doubletrouble 13 posts

Doubletrouble 13 posts -

Mace 3 posts

Mace 3 posts

Most Popular Posts

-

Interesting - not what I was expecting. I was expecting to see rail pressure below 4500 psi while cranking during the hard start. That would have made sense as the ECM would not have turned on the i

-

It is possible. I have worked on a few common rail Dodge Cummins engines. What I have found is that it can be very difficult to troubleshoot this fuel system, even with the use of the right diagnost

-

That should eliminate it from drawing in any air then.

Hey Gang,

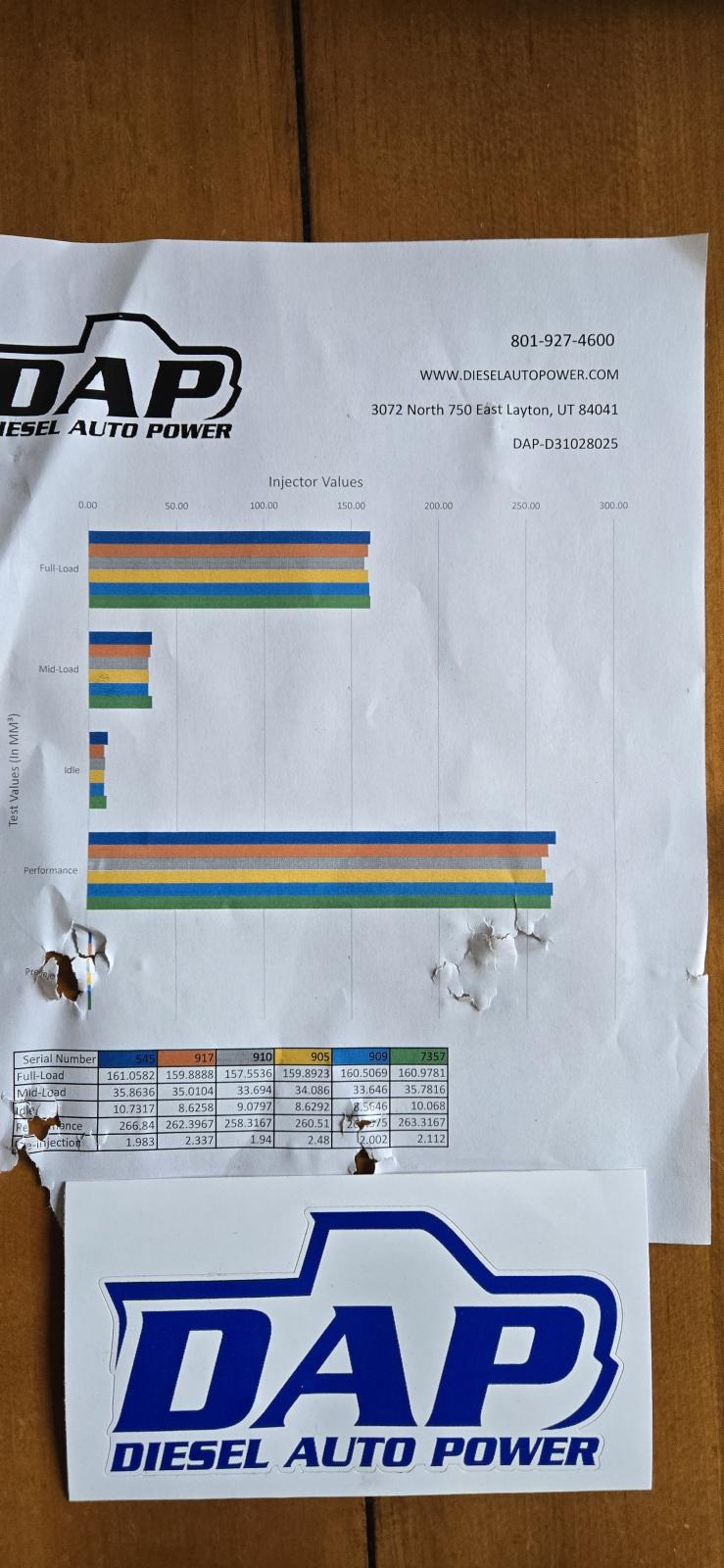

I've managed to get Thor running for the first time in 2 years. I opted for a stock fuel pump for right now since I'm missing parts yet for the AirDog 150 fuel system I've got I'm looking for a bracket for the pump. I have good positive pressure for the CP3 injection pump. I need to find out what the misfire and studdering are about. Cold start it's a bit long cranking not bad. Once it starts it runs rough and smokes white. I've got a set of @dieselautopower +50 HP injectors installed and had them sent back to DAP and found one injector had an issue and was repaired and sent back. Then I ordered a set of o-rings and replaced all o-rings on injectors and cross-over tubes.

Once warmed up all roughness is gone. It runs good and strong for what it is. I can even do the oil cap test and the cap does not even move. I'm trying to figure out the cold idle roughness and warm up smoke them once warm it drives and runs great. Even yesterday I drove to town and got 50 dollars of fresh diesel fuel to make sure its got enough cetane and pour point depressants. Currently 39*F here. Last problem in this category is the grid heater light came on yesterday and dinged 10 times signaling its high flow rates of the CP3. It idles at about 7,9xx PSI of fuel rail. At 1,500 RPM its pumping up to 11,8xx roughly and appears the fuel rail is building good pressure.

With Thor being my project I plan on writing articles as I get things figured out. So anyone give me a hand on this? Monday I'm going to put insurance and registration on Thor and he's going to become my daily runner. Why? Beast finally needs shop time and the rear main seal is leaking. Thor becomes the primary rig for now while I gather supplies for Beast and get my help here to remove the transmission and transfer case so we can access the rear main seal.

Thor is also going to lose the heavy flat bed and front bumper soon. I'm going back to the lighter factory box and tailgate then factory bumpers and ditch close to a full ton of steel. Thor is fat at 9,300 pounds even empty.