- Replies 31

- Views 7.7k

- Created

- Last Reply

Top Posters In This Topic

-

rdsutton 13 posts

rdsutton 13 posts -

ISX 8 posts

ISX 8 posts -

bjytech 3 posts

bjytech 3 posts -

rancherman 2 posts

rancherman 2 posts

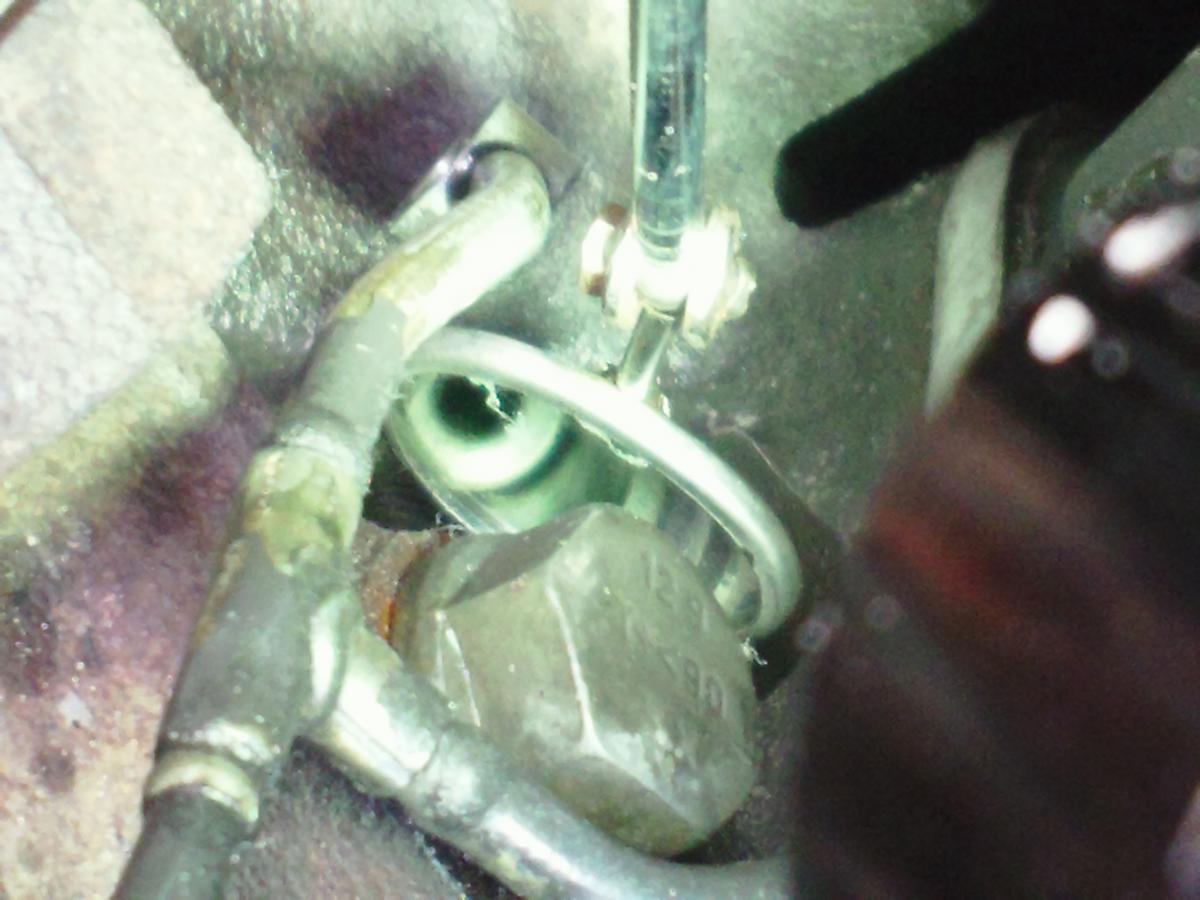

Installing new injectors 5x0.014 on truck in sig this weekend, would like to know what some of you put on the injector sleeve and locator ball to keep it from sticking/seizing in the head? Thanks Dave