Welcome To Mopar1973Man.Com LLC

We are privately owned, with access to a professional Diesel Mechanic, who can provide additional support for Dodge Ram Cummins Diesel vehicles. Many detailed information is FREE and available to read. However, in order to interact directly with our Diesel Mechanic, Michael, by phone, via zoom, or as the web-based option, Subscription Plans are offered that will enable these and other features. Go to the Subscription Page and Select a desired plan. At any time you wish to cancel the Subscription, click Subscription Page, select the 'Cancel' button, and it will be canceled. For your convenience, all subscriptions are on auto-renewal.

- Replies 246

- Views 40.4k

- Created

- Last Reply

Top Posters In This Topic

-

rogerash0 97 posts

rogerash0 97 posts -

jlbayes 33 posts

jlbayes 33 posts -

Me78569 32 posts

Me78569 32 posts -

Mopar1973Man 23 posts

Mopar1973Man 23 posts

Most Popular Posts

-

they prob kill themselves after dealing with all the oddities of the electoronics.

-

If you came into my shop to have a transmission built, with a 62mm top turbo and that large-housing S475 on the bottom, I would recommend a stock stall speed converter. I would recommend either a Goer

-

Featured Replies

Did This Forum Post Help You?

Show the author some love by liking their post!

Welcome To Mopar1973Man.Com LLC

We are privately owned, with access to a professional Diesel Mechanic, who can provide additional support for Dodge Ram Cummins Diesel vehicles. Many detailed information is FREE and available to read. However, in order to interact directly with our Diesel Mechanic, Michael, by phone, via zoom, or as the web-based option, Subscription Plans are offered that will enable these and other features. Go to the Subscription Page and Select a desired plan. At any time you wish to cancel the Subscription, click Subscription Page, select the 'Cancel' button, and it will be canceled. For your convenience, all subscriptions are on auto-renewal.

Hey guys,

I cant find the thread I was reading where you all were talking about the PSG being the actual 65HP limitation /w the smarty or non wire tap programmers on the vp44. I got interested and I found a lot of info out there, primarily some french guys where I used google to translate. showing clips to read the 24 series eeprom with 3M clips. They eventually caught on that you could put 5v to one of the legs on the chip and make it no longer read-only (this is common, and I suspected it). Because their forum is invite only I couldnt download their diagrams or documentation they created. I also found some Indian website that showed how to read/write to the PSG /w an arduino, including wiring diagrams and so fourth. I cant find that in my history now either, but its in there somewhere. Anyways, here's the french lads that tackle read/write to the PSG. Every time they say "code", i think they mean "encrypted". I tried to join the French board but it seems to be invite only.

https://translate.google.com/translate?hl=en&sl=auto&tl=en&u=http%3A%2F%2Fwww.tlemcen-electronic.com%2Fforum%2Fshowthread.php%3Ft%3D12157

So bottom line is, I think we could read & write from the eeprom. The question is who is going to modify the code. I know somebody was saying it was encrypted, and that wouldnt surprise me, but it sounded like the french lads were pulling it encrypted. If we could find out what it's encrypted with, and we rented some Amazon AWS servers, run a linux shell to brute force it or rainbow table it, whatever it be. I have to guess that 1998 encryption schemes would be very crackable these days. The Geforce 1080 is no joke /w 2x the power of the 980 and half the power consumption. I saw 3M connectors to read from it without taking it off the board. It sounds like they wrote to it by enabling 5v on the correct pin/leg of the chip (I dont know which exactly b/c I couldnt get to their attachments), but soldering a new one on /w a fresh flash is something I imagine could be more convenient. I did come across pin diagrams for the chip on either their site or another. I dont know if you'd have to take the 5v away from it after the write, but by the way they talked it didnt sound like it. Hard to tell through translation, though.

Other interesting links:

https://translate.google.com/translate?hl=en&sl=de&u=http://www.vp44diesel.de/de/pumpen-vp44-psg-16&prev=search

http://codecard.eu/carprog/software/by-obdii-for-opel-psg16-diesel-pump-read/repair-mileage-read-pin-reset-ecu/prod_375.html

I requested an invite code, see post #6 here http://mhhauto.com/Thread-zafira-pump-psg16-replacement-and-programming

Cheapest place I have seen carprog http://www.ecutool.com/CARPROG-FULL-with-all-Softwares-Activated-and-all-21-Adapters_8243.html#5

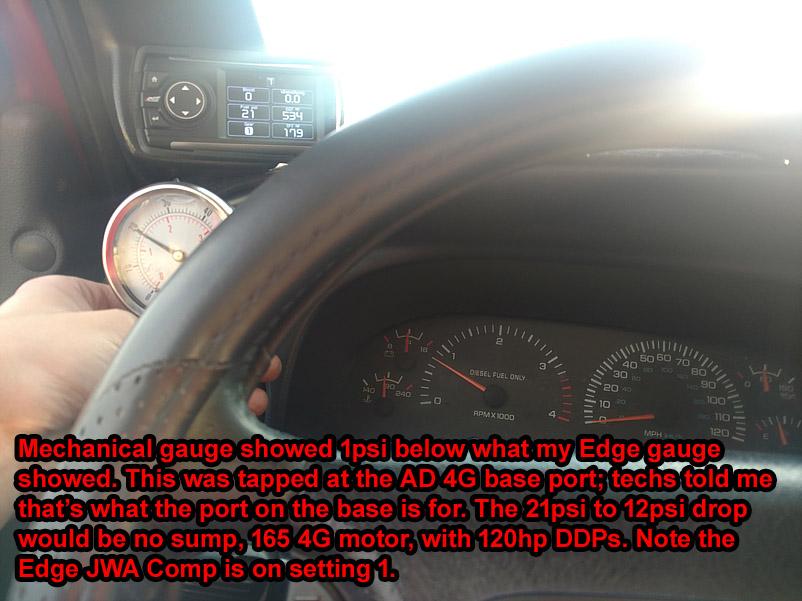

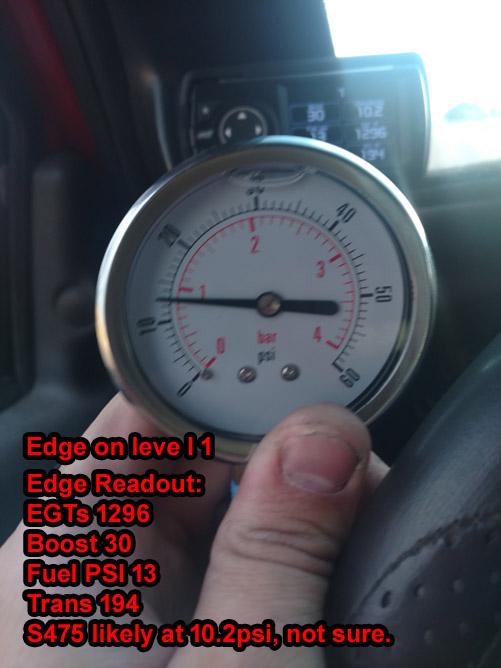

Essentially I recently became knee deep in this hobby. I have a 98.5 24v /w D&J motor built to 700hp spec /w CNC'd head on intake & exhaust, 62/68/0.80 + S475/96/1.32 twins, currently running 50hp inectors /w new Edge Juice Comp with smarty SO3 on the side. I have 120hp DDP injectors next to me that just got backfrom warranty, which Lenny looked at personally. The first time around Brian handled it. I've spent a lot of time fixing drive pressure and boost pressure leaks, I think they are 99% sorted based on the performance I'm feeling. I need to do another boost test leak. More on things: 5" down pipe, mishi rad & intercooler, banks monster intake, blah blah. Still only seeing 43lbs of boost. Without the wiretap I only saw 28 psi max on a brand new Industrial Injection VP44. After putting my old pump back on, that is wiretapped, I once again saw 43psi. This is what enlightened me to the necessity of having proper fueling. I'm so far into this VP44 platform now that I wont be switching to CP3, unfortunately. Got it all mated to a Firepunk Comp I in a ext cab LB chassis. I paid some guys to work on my truck and was so let down that I learned the hard way, the only way is to do it yourself.

I come from a background of computers and dirt bikes. My dad was a firmware/software/hardware engineer who came to the US from Australia. Due to him being an alcoholic I wouldnt waste my time asking for his advice, but once upon a time he was very smart knowing low level stuff like assembly (programming), layers to protocols, making PCB's, soldering them all up, programming them all up, etc. Credit card readers & bill acceptors seemed to be his bread and butter primarily. Also some assembly line stuff like productivity displays, etc. For roughly 20 yrs he worked solo as his own contractor.

Perhaps this could lead somewhere? I'm considering sending back my II VP44 for a hodrod pump, seeing as my tapped reman VP44 that came on the truck is running just as good & better with the wiretap. I had previously bought the new std output VP44 from II as a method to troubleshoot a hard-start condition when (almost) eveyrthing else had been tried. Turned out to be a drive pressure leak @ the 90* hot pipe connecting the turbos -- I fixed it, and the truck starts as it should.

Sorry if this is in the wrong section.