- Replies 58

- Views 8.2k

- Created

- Last Reply

Top Posters In This Topic

-

Marcus2000monster 23 posts

Marcus2000monster 23 posts -

Mopar1973Man 12 posts

Mopar1973Man 12 posts -

dripley 8 posts

dripley 8 posts -

Me78569 3 posts

Me78569 3 posts

Most Popular Posts

-

I know I am posting this a little bit late, but I wanted to clarify some things. I also apologize for any confusion on my part as to whether you should use the hand-operated vacuum pump or use the en

-

I will vouch for the 4x4 posi-lok as well. I no longer worry about my actuator failing on my 98.5 at the worst time and the 2WD low is great for backing trailers.

-

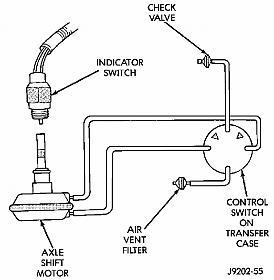

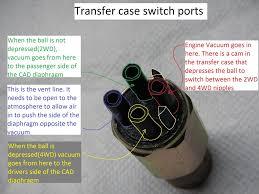

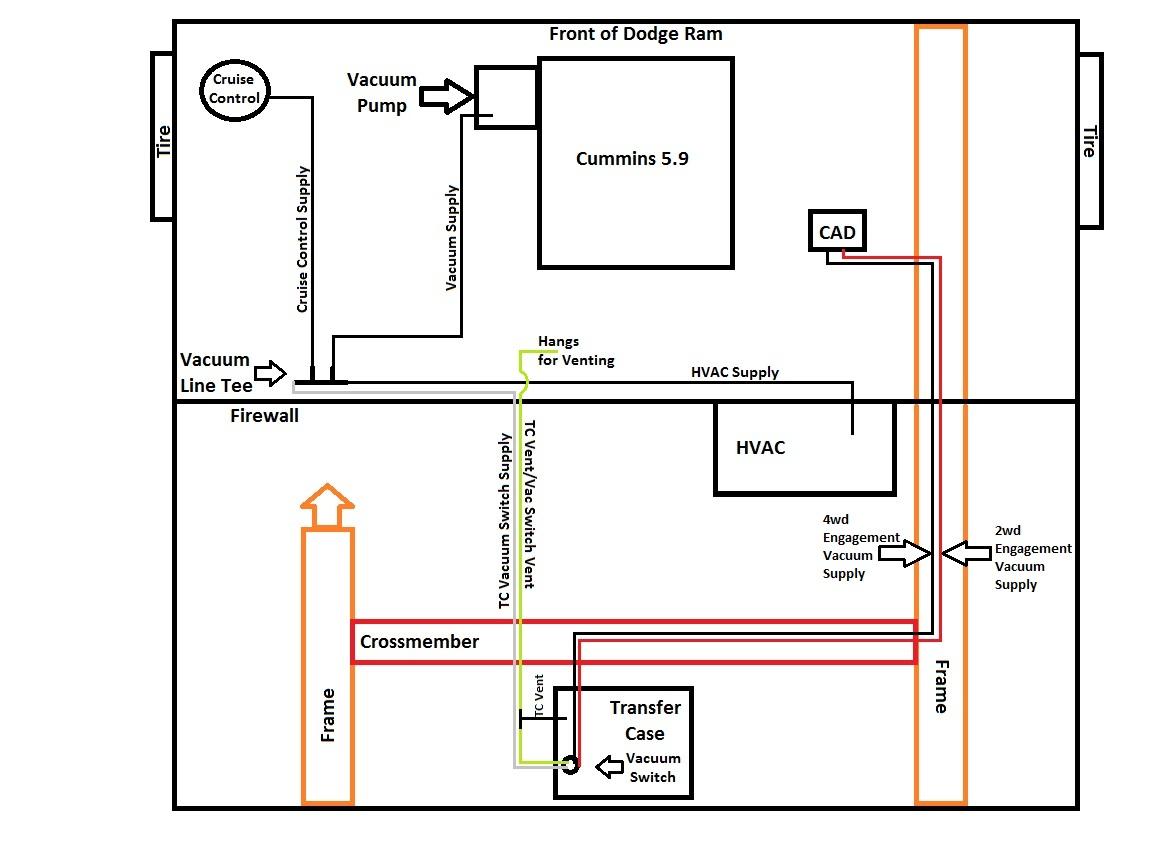

A hand operated vacuum test pump is a good investment, is not that expensive, and will allow you to accurately diagnose vacuum related problems. For example, the CAD unit can easily be te

Ok guys I honestly hate to start another thread but I have a serious problem. It is the dead of winter and my 4x4 won’t work! The engagement stick moves into place but no dash light or 4 wheel drive! I need to get this fixed ASAP! I used it last week so it worked fine then. Help?