How Many Times Can You Use Stock Head Bolts?

- Replies 37

- Views 8.3k

- Created

- Last Reply

Top Posters In This Topic

-

TheGreatWhite 14 posts

-

Dieselfuture 3 posts

-

Me78569 3 posts

-

AH64ID 2 posts

Most Popular Posts

-

Depending on a shop, maybe 80-100 to surface, plus they usually tank it in cleaning solution it may be extra it may not. And just depends on how busy they are, the job itself may be half an hour or so

-

if you have the money, do studs. All that work to resurface just isn't worth the risk in my mind.

-

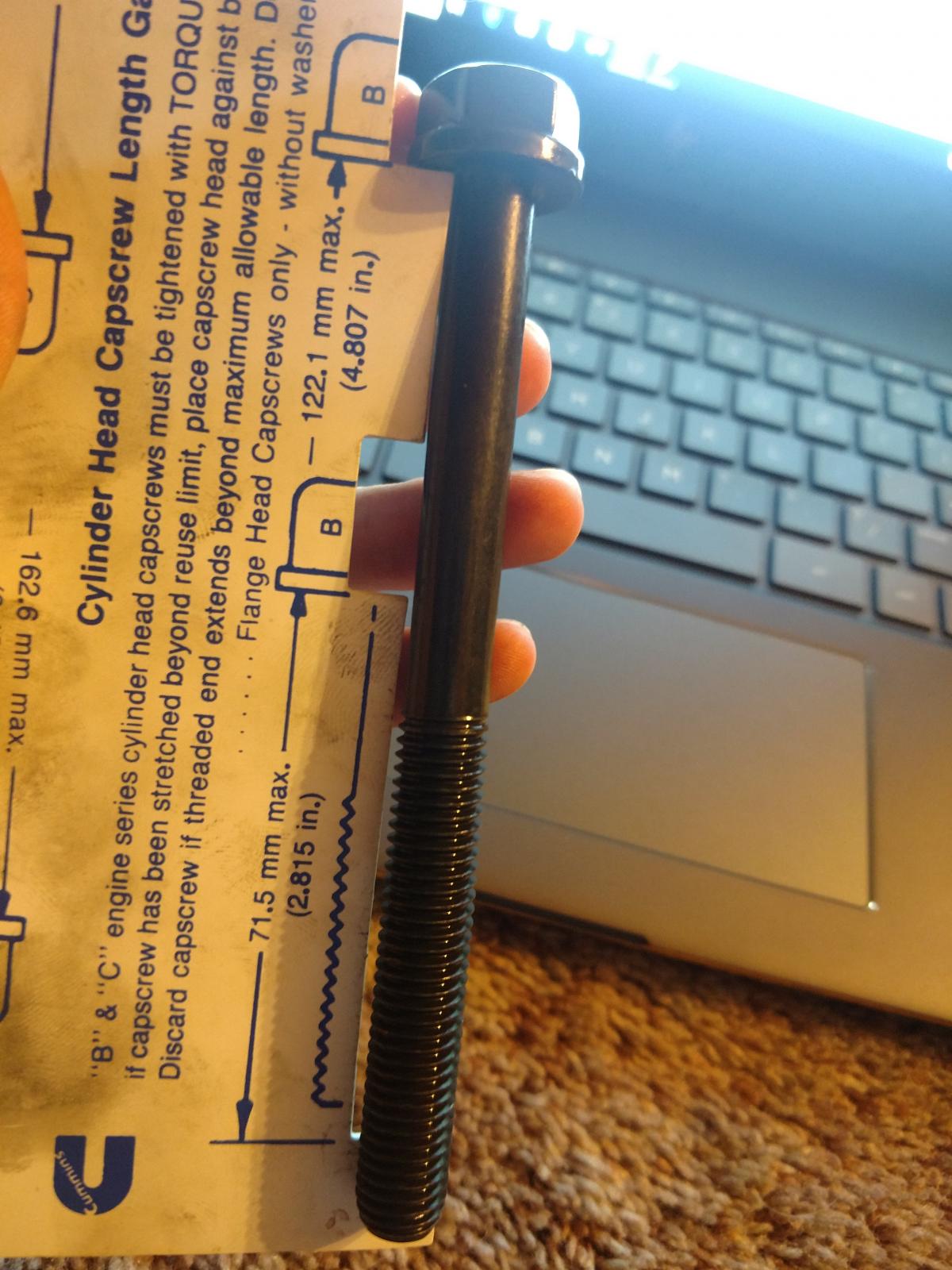

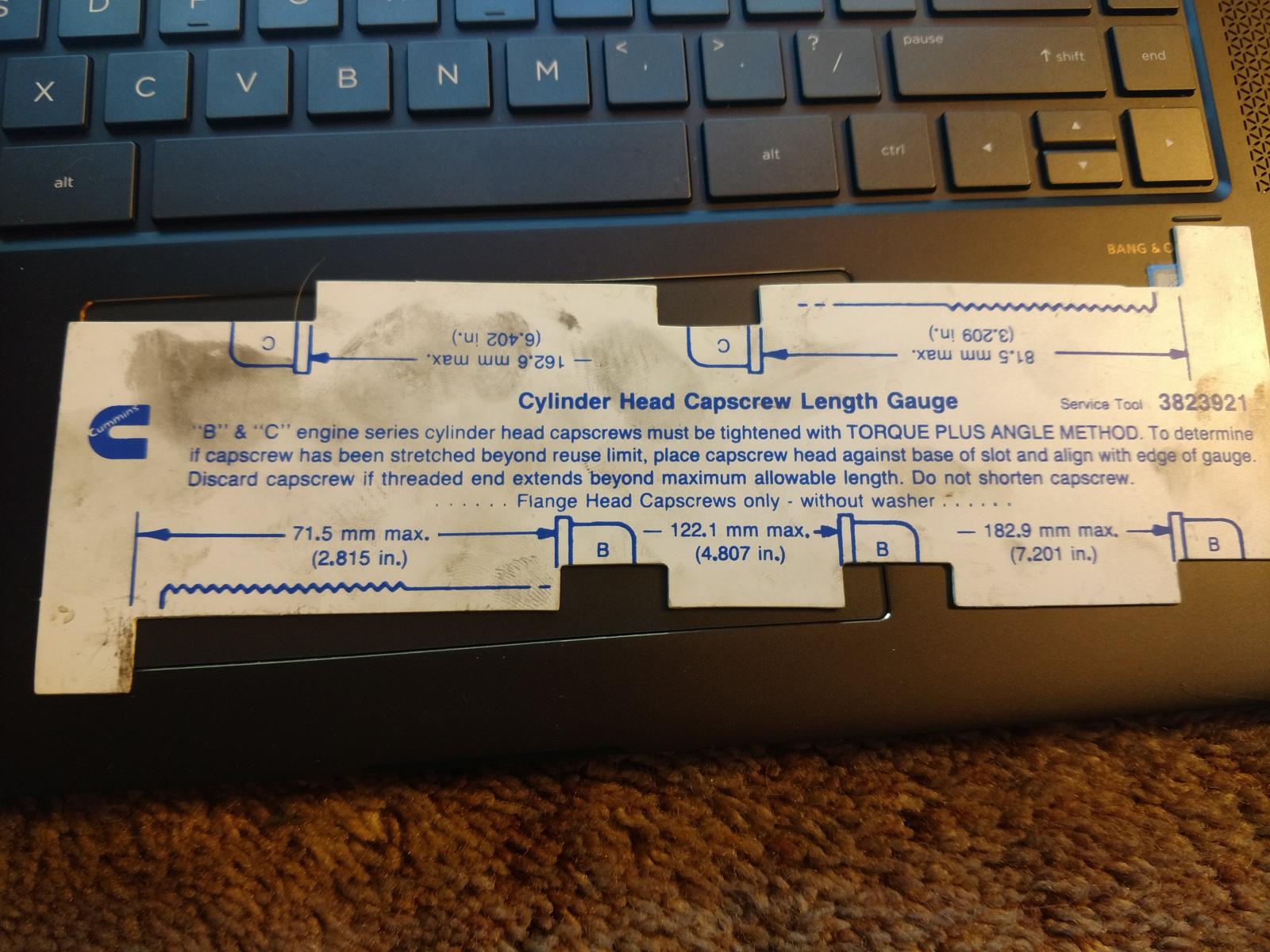

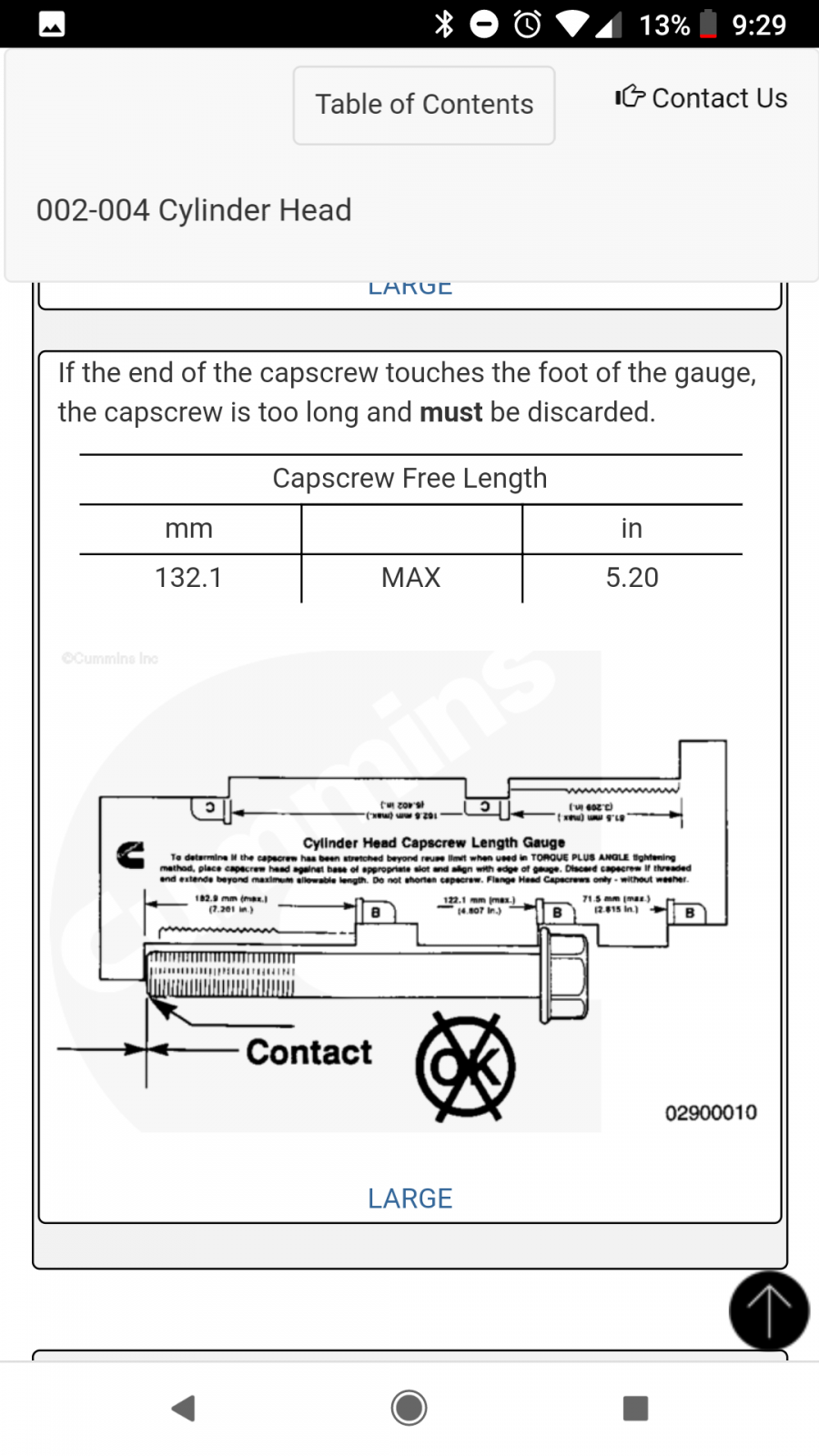

If they are all in spec I don't see a reason to not reuse them.

After coming up with different ideas on how to put this 02 motor in my new-to-me 99, I somehow stumbled into an extremely good deal on a 99 motor with 293k. Guy that still owns it (as of 7/11 I have not picked it up yet) took the head off to check the cylinders to make it his race truck, but decided to do something else. Moral of the story is it needs a new gasket and I am wondering how many times you can reuse the bolts, can I save some money and reuse them? Or is it better to just go buy some ARP or upgraded bolts. Anything helps, thanks!!

TL;DR: How many times can I use the stock head bolts because I'm cheap.