- Replies 56

- Views 11.2k

- Created

- Last Reply

Top Posters In This Topic

-

Octafish 15 posts

-

Bullet 12 posts

-

Gregturley 8 posts

-

IBMobile 6 posts

Most Popular Posts

-

you wont regret it...Richard has responded to my emails on sundays. i installed mine around 2015, no belt or pulley issues...even spent some winters in Wisconsin, Minnesota area. i have my

-

You can prime it with an electric drill very easily. Mine is also 18 psi at idle but will increase to 20 during a full throttle pull. Never less than 18 though.

-

I used stock lines with 3/8 hose. No problem at all. Stock pickup in tank. I have RV275 injectors also.

.jpg.17662a3a3b3375c2079abacd0d5bdc64.jpg)

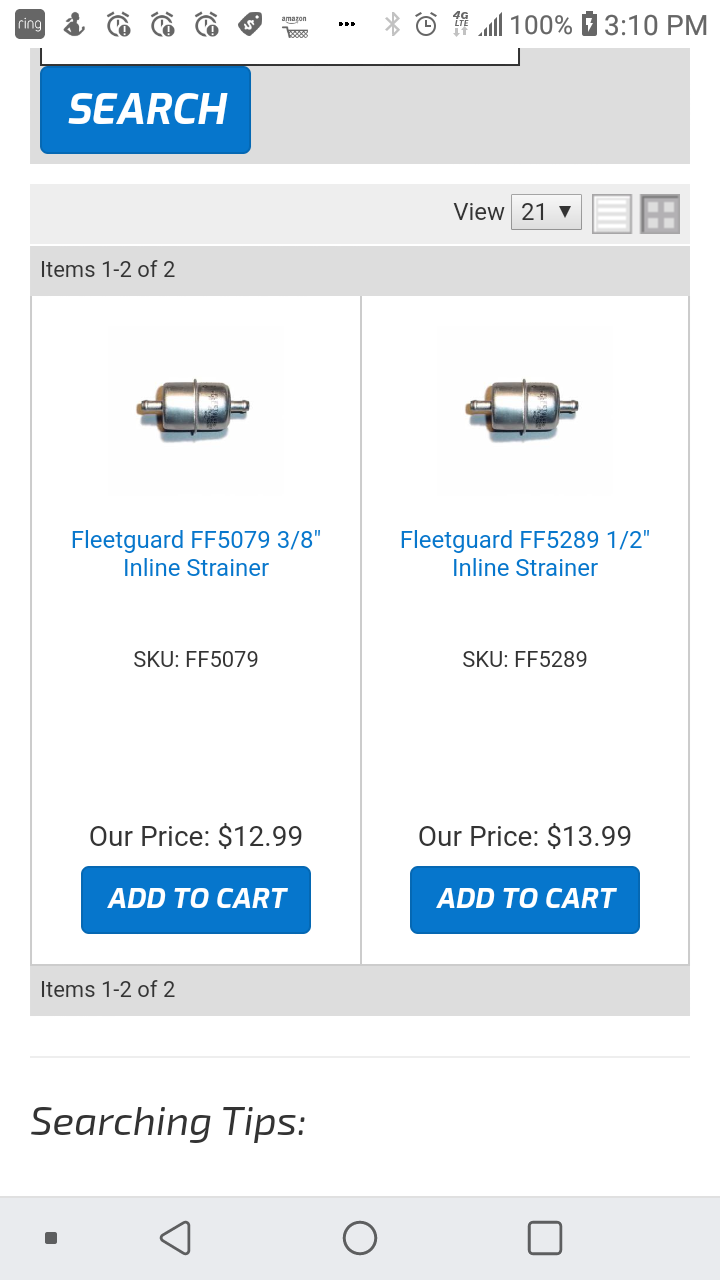

What do you guys think?

Does one have an advantage over the other?