New DAP 100HP SAC 7x9 injectors

- Replies 26

- Views 8.5k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 10 posts

-

01_Cummins_4x4 7 posts

-

Silverwolf2691 4 posts

-

Me78569 3 posts

Most Popular Posts

-

dont make any decisions until they test them for you. For %99 of the guys out there stock pop is fine.

-

The ho pump is not causing the issue. Ho's are plenty fine with 100's

-

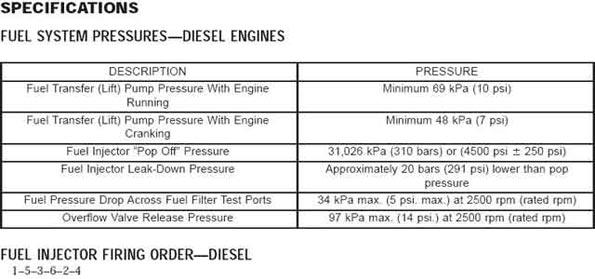

Same 310 bar is what the injectors are suppose to be set for. Right out of the Dodge FSM...

I just got my replacement injector yesterday since one of them from the original 6 was causing a severe miss at idle, like the pop off pressure wasn't set right.

I put the injector in my 01 Dodge Ram 2500 Cummins HO 6 speed 4x4 that I bought 12/5/2020, and it doesn't miss now, but it lopes like it has a cam in it. Unbeknownst to me as this is my 1st HO Cummins (my two previous were '99 Ram 2500 Cummins with a 47RE trans and SO VP44 pumps. I just found out that my Industrial Injection VP pump that is on my pickup when I bought it, is the HO pump. Apparently since the HO pump is a low volume/ high pressure pump, it can't provide enough fuel to feed the 100 HP injectors, hence the idle not being as smooth as normal. I removed them last night and installed my stock Bosch injectors and it runs smooth like it did before I installed the 100 HP injectors.

Since I only put 10 miles on the injectors, can I send them back and exchange them for 75 HP SAC injectors?

Thanks,

Doug

Edited by 99_Cummins_4x4