Welcome To Mopar1973Man.Com LLC

We are privately owned, with access to a professional Diesel Mechanic, who can provide additional support for Dodge Ram Cummins Diesel vehicles. Many detailed information is FREE and available to read. However, in order to interact directly with our Diesel Mechanic, Michael, by phone, via zoom, or as the web-based option, Subscription Plans are offered that will enable these and other features. Go to the Subscription Page and Select a desired plan. At any time you wish to cancel the Subscription, click Subscription Page, select the 'Cancel' button, and it will be canceled. For your convenience, all subscriptions are on auto-renewal.

- Replies 40

- Views 22.5k

- Created

- Last Reply

Top Posters In This Topic

-

Ldrivon 21 posts

Ldrivon 21 posts -

Wild and Free 9 posts

Wild and Free 9 posts -

ISX 6 posts

ISX 6 posts -

pepsi71ocean 2 posts

pepsi71ocean 2 posts

What is the Noise?! 9 members have voted

Featured Replies

Did This Forum Post Help You?

Show the author some love by liking their post!

Welcome To Mopar1973Man.Com LLC

We are privately owned, with access to a professional Diesel Mechanic, who can provide additional support for Dodge Ram Cummins Diesel vehicles. Many detailed information is FREE and available to read. However, in order to interact directly with our Diesel Mechanic, Michael, by phone, via zoom, or as the web-based option, Subscription Plans are offered that will enable these and other features. Go to the Subscription Page and Select a desired plan. At any time you wish to cancel the Subscription, click Subscription Page, select the 'Cancel' button, and it will be canceled. For your convenience, all subscriptions are on auto-renewal.

The Mystery Knock...

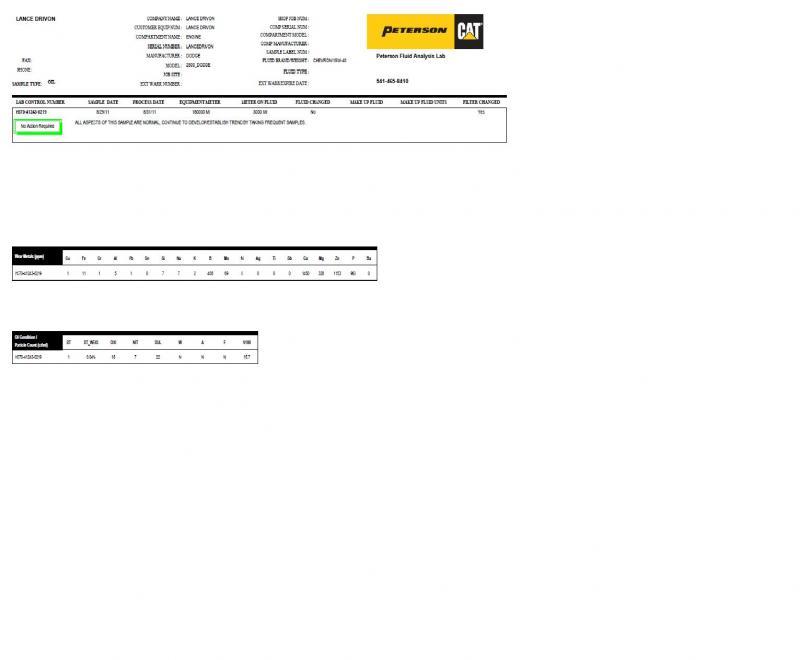

Written By Lance Drivon

With a Bottle of Melrose Merlot 2006

:spend:It all started out in that nice May evening in 2010 installing my new plate, gauges and exaust. After installing them all and about to take off on her maiden voyage after startup I draw in a tip off a Snap-On pick that the previous owners mechanic had broke of in the inercooler boot that I wasnt aware of. BANG BANG BANG BANG.....I went cold. The riveting noise of that hollow clock clock clock noise.... SO I take it to a Mechanic who works on Big Rigs and light duty Diesel trucks. They pull the head,drop the pan. Head gets milled and magnufluxed. New genuine cummins parts gets put into engine. They said the engine looked virgin. New Piston. Cleaned cylinder. All back together and ready to seat the rings on the #1. I run it nice for about 2000-3000 miles and then start working her.So within the last few months I notice a noise.

So I had accidently brought her to :nono:1600* 2 times for 4-6 seconds each time but didnt notice any noise after.(:thumb1:I was showing my dad My 96 could kill his 01...and it did.) Not the transfercase rattle:nono: but another noise. So I fix the transfercase rattle and now I can hear it beter..

New Liftpump...

New Overflow Valve...

New Fuel Filter....

Injectors Pop tested and adjusted by Oregon Fuel Injection...

Adjust Valves...

Pull all return lines and supply lines away from cab...

Adjust valves...just incase the first time was wrong...

The noise is still there. When I brought it back to the Mechanic they said they hear something but its nothing they reconize. I take it the next day to another diesel mechanic and its not there at idle this time. At 65 you can hear it claping away like a hydraulic lifter but softer. Some days its louder. Somedays its hardley noticeable. It has become more noticeable at idle cold sometimes.. Sometimes not.. Your really have to squint and listen to it sometimes and sometimes you can hear it just over the combustion noise of this loud critter and its crazy injection pump.

Things I am thinking starting in order of what I think..

Piston Melted from hot pulls at 1000-1100* and the few short times of 1600*?

#1 wristpin boss in piston cracked and making noise acording to heat or cracked piston?

Exaust valve hitting piston because a thicker head gasget not used when put back on?

P7100 pump #1 plunger getting hit by its cam causing a clap knocking sound. The reason I say this is that the #1 injection line will make your ears bleed and the rest of them sound the same to each other. Your ears will be numb a little and ring after listning to the #1.

rod bearing but unlikely with the noise. Its not getting louder and louder...It comes and goes in volume. Seemes louder when colder <sometimes>.

The truck runs smooth. No white smoke. Starts great in cold mornings. 35 psi boost and I adjusted the afc with a regulated air supply to get the settings close. I am thinking of buying a bore scope and inspect the pistons. I found out From Moparman1973 the injector nozzels are 9/32" so i found a bore scope for $100 with a 5.8 mm head and shaft I can use to inspect them. I have to order it but I need some input on will a injection pump make a noise when the plunger is getting stuck or if a piston is melted or cracked smacking the head or cylinder.

Hope someone has had something like this before and I am starting to warm up the old knuckes for some finger bleeding work here.

Thanks in advance guys!

My wife is convinced I have gone mad but she has a 2001 2500 and she understands whats its like.....VP$$.......:evilgrin:i mean VP44