Everything posted by Mopar1973Man

-

New to Auto Transmissions

Think about your purpose mostly. What is the plan for the truck and what will it be used for the most? Then build this truck for that purpose and enjoy the craft you made! I totally understand why some like the automatics for the stomp and GO! Just one thing to keep in mind, automatics like to have a final ratio closer to 3.73 after tires to reduce the stress on the internal parts. So to make sure you figuring your tires in the part of the design too!

-

24v - Ram 1500 Cummins

Something to double check that rubber mat flooring is typical for rotting out the floors. You might lift the rubber and double-check the interior metal for any rust. One of the common conversions I have to do was pulling up all the rubber mat flooring and fix all the rusted floor metal and then convert to carpet. I've done this in a few rigs that people had rubber floors. Typically the drivers floor pan is rotting.

-

New to Auto Transmissions

Personally I prefer the 5 speed NV4500 over an Auto. Even cheaper to rebuild a 5 speed than any 47RE. Just consider billet shafts for an 47RE.

-

New to Auto Transmissions

As for the NV4500 series talk to @Doubletrouble he's actually rebuilt his own transmission for a 5 speed. 5 speeds are easy to rebuild according to DoubleTrouble. When I had the relationship with Dynamic Transmissions he showed me that in a 12 hour day you can rebuild a transmission fairly easy. The only special tool is a press for unloading the spring tension in the overdrive basket. Everything else is standard hand tools. As for rebuilders. Be careful, you don't hook up with a guy who only builds racing transmissions. A lot of people opt for low stall converters and shift kits that may be rather harsh. Consider the purpose of this truck and what it's going to be used for. Be very clear to anyone doing your rebuild that they understand what the purpose of this truck is. Like out here, low stall would be bad, as it would operate the engine at too low an RPM, climbing mountain roads with a max speed of 15 to 25 MPH. Why I like my manuals, they don't care till your hauling heavy, then you'll see the trans temp rise. Racing is one thing daily driver is another, where you don't want to be too late for a shift or too early. That was one part of the 46RE I didn't like: 4th gear typically dropped in and locked up way too early.

-

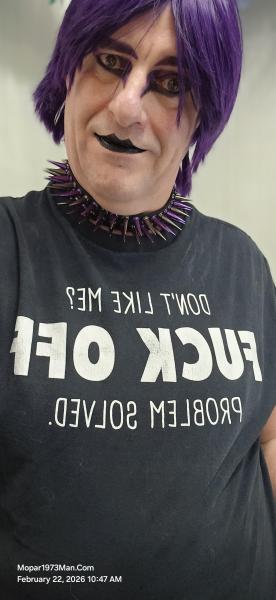

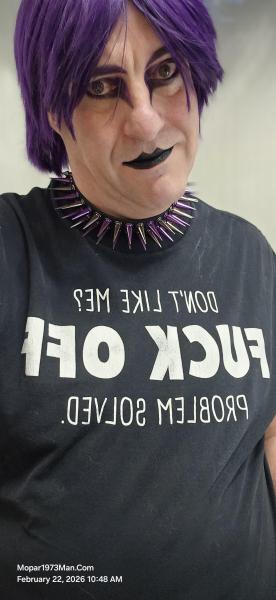

Playing with makeup and creating changes...

I've had a few people who asked for a tutorial on how I do my makeup design. Let's get started! Start with a full shower for me, then shave right afterwards, for less skin irritation. Then afterward, get dried off, and I use Elf tracky primer because I have oily skin and tend to have fallout without a primer. Using a black eyeliner marker. I draw from my inner corner of my eye toward the top of the nose, as well the tip of the nose. This gives me a framework. Now as for my flame style eyes. You are going to need 3 brushes I like the thin but flat brush for applying this. One brush for red, ornage and yellow. Add the black to the bottom. Now break it down even more on the left eye... Starting with a deep red, darker tones look deeper in the corner of my eyes. This is a mid tone orange that lean a bit red side. The center part of my eyelids and the bridge of my nose on each side. Yeah I'm not worried about the little line mess there even. Now you have the final area of adding the yellow color to the temples. Then a bit of yellow pat into the tip of the nose. Pat carefully and pack the powder in. This actually shows up much better in white face... Eyebrows... I've shaved back my eyebrows some to allow for colors to show better. Eventually I'll ditch my eyebrows but not yet. Just repeat the red and the orange as you did for your eyes in the same zones. Little lipstain in black and finalize your clothing and jewelry. Now the last step the hair...

-

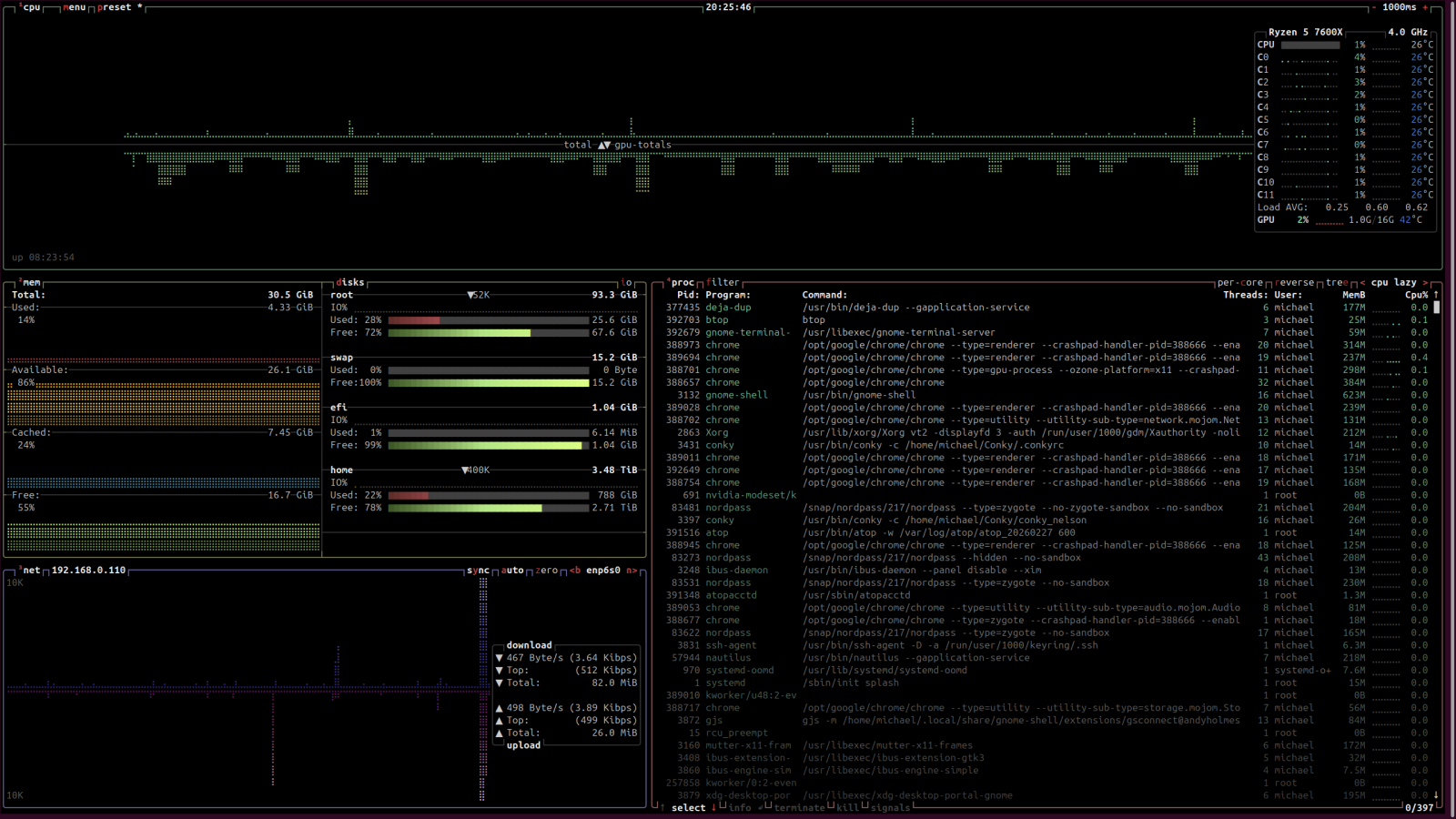

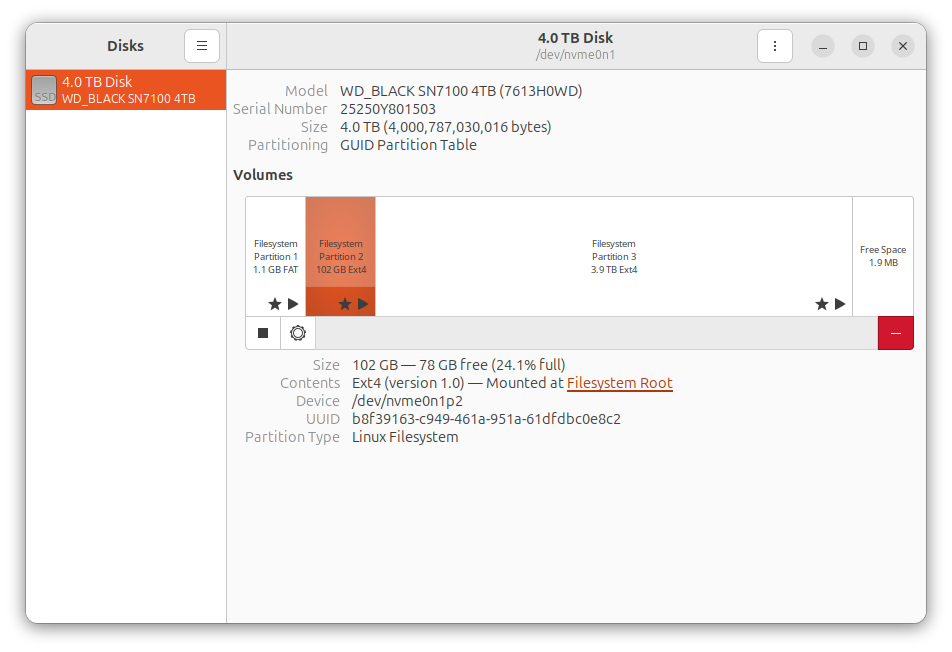

Memory and system usage challenge

I'll show you all my workstation. 12-core AMD processor 32 GB of RAM and only barely 15% used 4 TB hard drive M.2 chip (22% used for home data, 28% used for the OS system (root) 1Gbit Network (CAT6 Cable) As you can see, my workstation has all the common-sized stuff that most Windows PCs today are build with. So now...I want anyone to post up the amount of memory used on their Windows 10 or Windows 11 PCs. My uptime is low because I had a kernel update for the machine, so a reboot is required. Hard drive usage is low for 4TB hard drive yet. Perk bonus for linux users. No more defragging hard drives, no more anti-virus software, nor malware scanning of your machine. Being that I isolated my OS system to its own partition this makes the system secure too. Since the OS system files are tucked away like this, and if there is any reason I need to reinstall my Ubuntu, due to a screw up on a setting or a crashed system, there is no problem. I can reload the operating system completely with no ill effect to the personal data. This is done by partitioning your drive so the operating system is not part of the home folder. Now, during the reinstall, just notify Ubuntu where each folder is and tell the software not to format the home folder. It will remain untouched. The only catch is having to reinstall your other software. Anyone willing to show off their Windows PC?

-

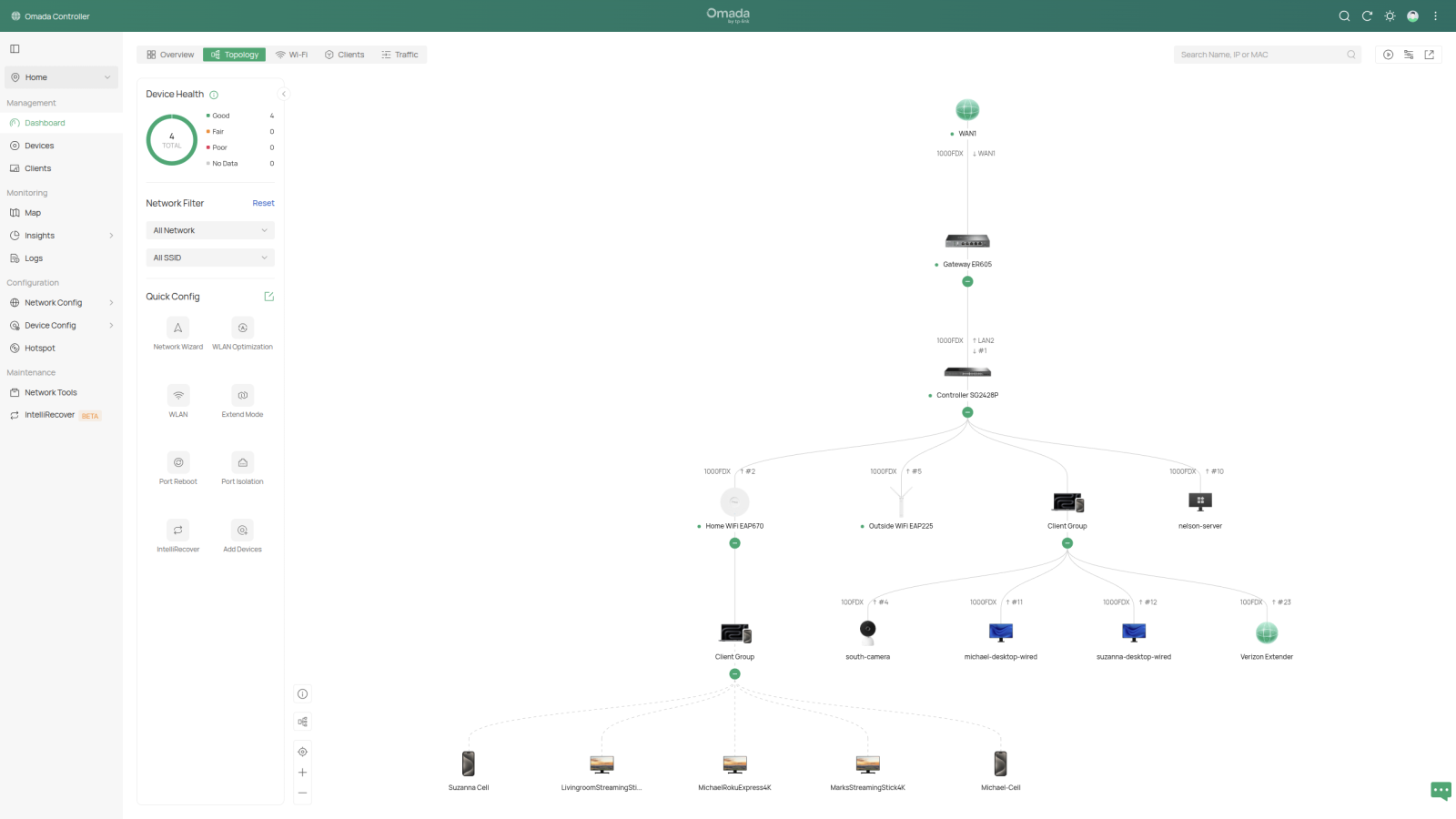

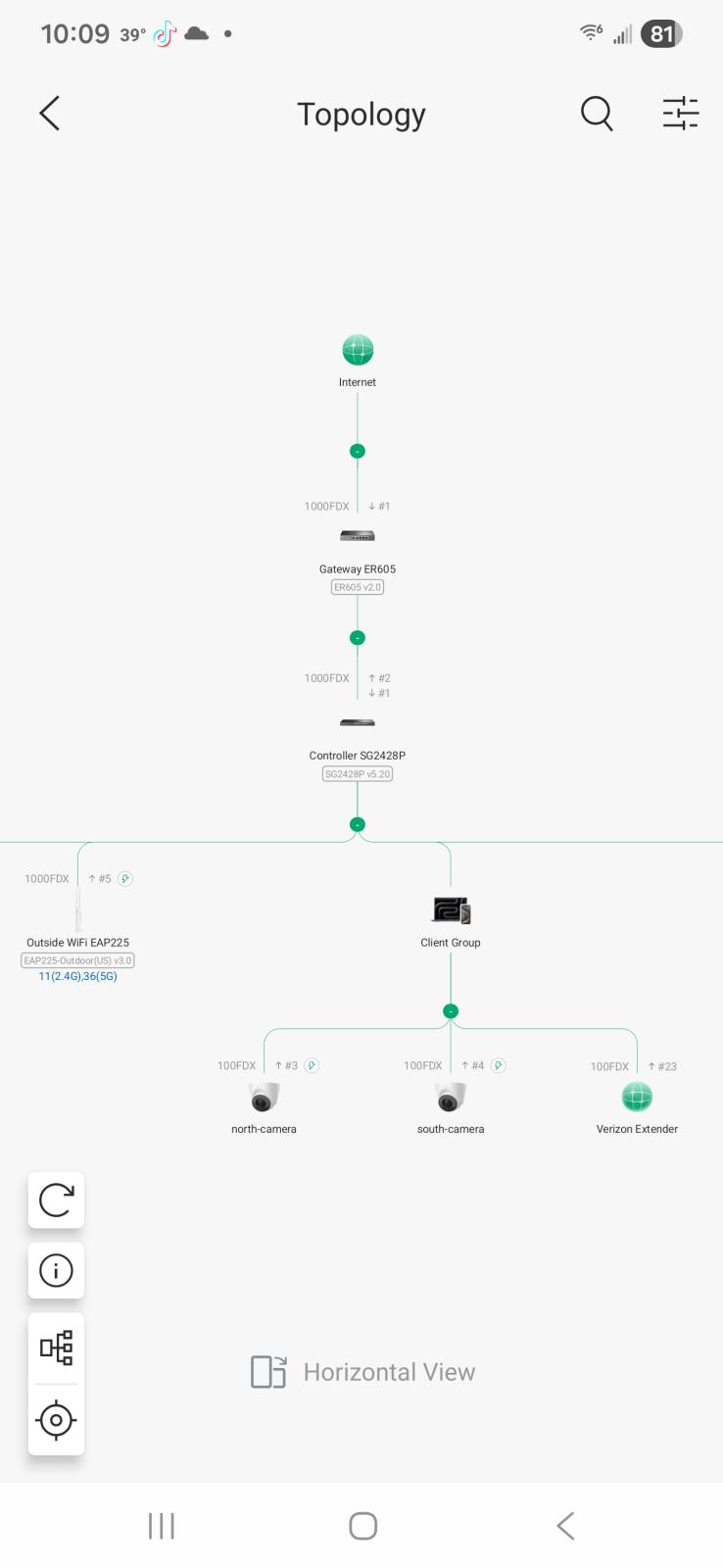

Old CAT5 cables, replacing with CAT6 cables!

Cables came, and I just found out the TP-Link switch I have can manage up to 48 Gbit signal across the entire network. All ports are limited to 1Gbit signals. So the cables for the workstations are top-notch and have a ping time of less than 1ms. I could have done the same with CAT5e and been cheaper, but I like the idea that I've got shielded cables now that are CAT6 rated. The best I've done is remove noise as a problem. I was showing @Tweety Bird the difference between CAT5 and CAT6 is that the jacket is thicker, with shielding foil/wire. This CAT6 is solid copper and not CCA (Copper Clad Aluminum). Then the divider in the middle to separate the 4 pairs.

-

New Kicker Speakers for Beast!

I found new cables for a pair for the left and right rear door for just under 30 bucks. Harfington55275106 Rear Left Right Side Door Latch Cable Fit for Do...Buy 55275106 rear left right side door latch cable fit for dodge for ram - pack of 2 black at Harfington, get more hood release cables in various size.

-

Beast is falling apart!

I love mine I finally got the rear camera mounted at the license plate. Great view and wide angle view as well. Touch screen allows for tipping the camera up or down like you would move your mirror. My setup required both directions of the camera to be flipped, and it works great. Records the GPS location in real time with your video, so position, speed, and direction are all recorded and will display even your road speed of recording, and even if you're talking in the cab. Mirror has voice commands as well.

-

Beast is falling apart!

With 503K miles on the Beast alot of stuff is going bad and falling apart. I need to take advantage of things I have access to and the time I have available when the weather is better. Plastics have been ordered, and I'm going to start restoring Beast. I just ran into a guy just down the road from me who has a straight rear bumper and will to just give it to me. Bonus!

-

Beast is falling apart!

Beast is falling apart completely. The plastics are failing left and right. I've got to pull the dash apart to fix a speaker problem. @Tweety Bird telling me just order the plastics and get them coming. I placed an order through LMC truck for the new plastics for the dash, and then found a smaller part supplier that has the rear quad door cables for a pair at $30. Cheap! Yesterday I was out and had enough dry weather to install the rear speakers and then move the rear camera to the rear bumper. The Wolfbox dash camera works awesome. New pair of door cables for the rear quad doors and then new dash plastics!

-

New Kicker Speakers for Beast!

This turned into a problem child to a degree. My driver's side rear door release cable for the inside door latch broke at both ends of the cable. Urgh! I'm going to repair the end hopefully with super glue and atime to till I can order the right cable. 20+ year old plastic is brittle. I've got to pull my dask bezel, and I'm sure more of it will break now, too. Argh!

-

New Kicker Speakers for Beast!

The other problem you starting to see how often im capable of working on my truck which is all based on weather now.

-

Old CAT5 cables, replacing with CAT6 cables!

Cables due to be here tomorrow. More to come.

-

New Kicker Speakers for Beast!

Now today I was wiring up the rear speakers and then lost connection on both left speakers.I pulled the front left apart and recrimp the connector solved. Now the left rear is dead no signal. I think a darn mouse chewed the wires in the dash. Ugh! More to come.

-

Old CAT5 cables, replacing with CAT6 cables!

Yeah. I would of bought a box and ends but I already have a 500 foot roll of direct bury outdoor CAT6 cable. I've even got two new cameras I want to mount to pole out in the yard. I need to clean up the yard in that spot so I can place a pole. Shop trash heap is in the way. Then run from the switch to both PCs is just barely 16 foot at the longest. 3 cables coming to replace the CAT5 cables. What bandwidth does your cameras run at? Mine seem to only hook up at 10/100 shown by the network. Just the Verizon extender too. Dang cheap CAT5.

-

10-4 App

Weird. I would consider either grabbing a small sample and testing both. Maybe catch the delivery truck and talk to him. See if your state has different policies. Last time I caught Maverik delivery I was able to find how much additives are being added.

-

10-4 App

Your problem could be the Edge Juice most likely too advanced in timing. Then how many miles on your injectors? As injectors wear out the pop pressure falls off for every 10 bar drop the injectors gain 1 degree advancement. This mean you would have to reduce timing in your tune to keep numbers up. Then the high cetane of biodiesel is lower BTUs but also needs less timing (retard) to burn efficiently. Quadzilla im starting at 12°BTDC at 1500 RPMs. Im not sure if your Edge has any timing adjust.

-

Titanium

My adventure of having a second run at bladder cancer and going back and forth to chemo treatments and surgeries. "Titanium" the character, kept me going and helped me with depression and stress of the idea I might not make it. I've made several new friends and found a new way to enjoy life as I continue to dress up and do my Titanium makeup. I'm always taking my adventure out into the public and share my artwork with everyone!

-

20260222_104448.jpg

20260222_104448.jpg

-

20260222_104500.jpg

20260222_104500.jpg

-

20260222_104510.jpg

20260222_104510.jpg

-

20260222_104533.jpg

20260222_104533.jpg

-

20260222_104757.jpg

20260222_104757.jpg

-

20260222_104800.jpg

20260222_104800.jpg

-

20260222_104806.jpg

20260222_104806.jpg

-

20260222_104807.jpg

20260222_104807.jpg

-

20260222_105445.jpg

20260222_105445.jpg

-

20260222_105453.jpg

20260222_105453.jpg

-

20260222_105458.jpg

20260222_105458.jpg

-

20260222_105502.jpg

20260222_105502.jpg

-

20260216_101906.jpg

20260216_101906.jpg

-

20260216_101913.jpg

20260216_101913.jpg

-

20260216_102016.jpg

20260216_102016.jpg

-

20260216_102020.jpg

20260216_102020.jpg

-

20260212_112151.jpg

20260212_112151.jpg

-

20260212_112203.jpg

20260212_112203.jpg

-

20260212_112530.jpg

20260212_112530.jpg

-

20260212_112535.jpg

20260212_112535.jpg

-

- 20260222_104448.jpg

- 20260222_104500.jpg

- 20260222_104533.jpg

- 20260222_104510.jpg

- 20260222_104800.jpg

- 20260222_104757.jpg