Everything posted by Mopar1973Man

-

Intermitten P1689

You might end up eating that VP44 but just maybe... I'll leave the lights on for ya and just post up.

-

Intermitten P1689

Depends on the location of the straw for the temperature. Hopefully, your straw is in the main fuel tank and not the sender basket. I'm assuming you are in the main tank area, being the 1/8 tank drop in pressure on hard sloosh. That would net you cooler temperatures in the fuel, being the hot fuel is kept in the sender basket. Is your warranty still good on the VP44 pump?

-

Intermitten P1689

If possible, maybe you could try unhooking the wire tap and see. No need to remove the entire splice, just unhook the wire. I think it's a heat issue on the PSG. By chance, what does the Quadzilla show for fuel temperatures?

-

20250415_154647.jpg

From the album: Thor - 2006 Dodge Ram 3500

-

20250415_154620.jpg

From the album: Thor - 2006 Dodge Ram 3500

-

20250415_154503.jpg

From the album: Beast - 2002 Dodge Ram 2500

-

20250415_154450.jpg

From the album: Beast - 2002 Dodge Ram 2500

-

20250415_154435.jpg

From the album: Beast - 2002 Dodge Ram 2500

-

20250415_154420.jpg

From the album: Beast - 2002 Dodge Ram 2500

-

Intermitten P1689

Did you do a W-T ground wire mod? Not good to leave a battery out. I know these trucks will run on a single battery but the passenger side typically is the source of ground for VP44, ECM, and PCM. W-T ground mod would move it to the driver-side ground for the VP44 and ECM but the PCM is still on the passenger cable. No such thing as a rebuild PSG unit. It's either USED or NEW. Sadly rebuild PSG is a poor choice being that it most likely not calibrated to your pump. The other part is Bosch Certified Rebuilt pumps it is a REQUIREMENT to replace the PSG with a new unit and be calibrated on the test stand. Most likely a bad solder joint in the repair of the PSG and the heat is causing a solder joint to open up. Yeah, I've seen a ton of people doing transistor replacements and weird home repairs but did they ever calibrate the repaired PSG to the mechanical part of the pump? No. This where problems start.

-

Badges and Achievements

Now subscribing members can see how much other members have contributed to the website. There are several badges that you can earn by just being helpful to other members.

-

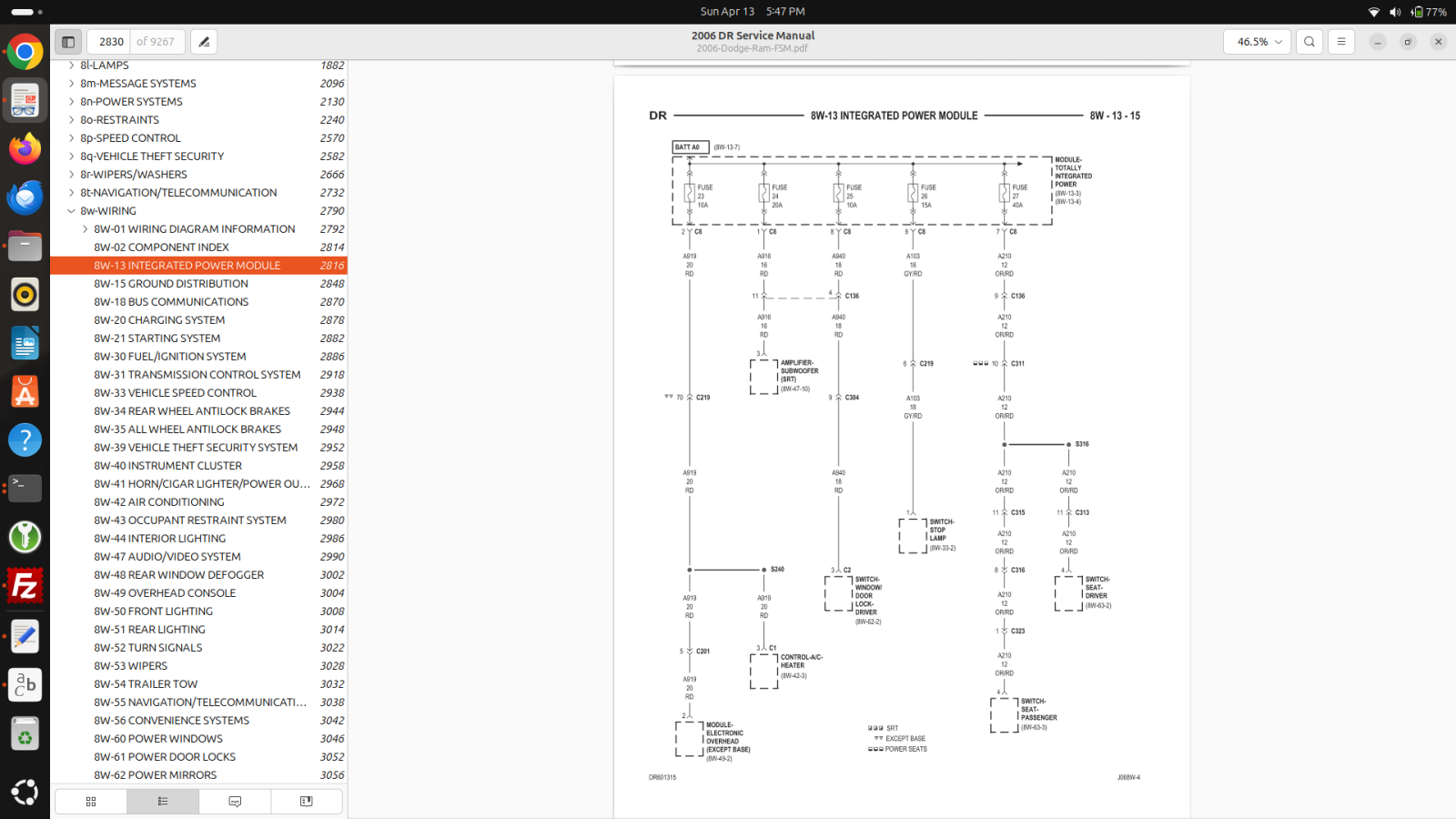

Hit the wall...

I spent some time this morning tracing out the brake light function from the cab to the taillights. Then I found out the taillight loom I got from a 2007 will NOT work. It's a single taillight setup. Problem I figured out that there are two taillights in the wiring diagram and then started looking for the white/tan lead nope. Not there. Now I'm on hold, waiting to see if the salvage yard has a 2005 wiring loom so I can get the right wiring. The project is on hold for a bit to sort out the electrical for the taillights.

-

Brake Light issue

SOLVED Make sure you get an 03 to 06 loom for the taillights. Funny part is 07 is single bulb taillight and 06 is a two bulb taillight with separate brake and turn bulbs. Already calling for 05 loom might be good swap at my salvage yard to do a swap.

-

Titanium, wows people for breakfast!

@Tweety Bird and I needed to run out and take care of a few things. I hopped in the shower and got cleaned up, and with fresh, clean skin and shaved, I started doing my makeup for the day. I did standard black makeup and wore my blue wig. Nothing fancy by any means but I've wowed another store worker today. @Tweety Bird and I stopped to get breakfast out, which I know of an awesome place for breakfast burritos. Old Towne Market has a small cafe in the back of the store. The gal working there I knew the gal at the counter; she took our order and handed the ticket back to me to pay up front. Ok. The gal at the till has kind of a blue-gray hair. I told her it looked awesome. She commented about my appearance. She was so intrigued about my appearance that she started asking questions then I revealed the cancer story somewhat, and she loved the fact I continue to do makeup and dress the part. Still, to this day, I get all kinds of stellar comments about my appearance. At another stop, I picked up a bit of fuel in Minnie. Now I'm pumping fuel in Minnie, and the older gent pulls in with a Ford 7.3L 1 Ton that looks awesome and is running great. Diesel man, I am. I gave him a kind comment about his Ford truck. I walked over after pumping my fuel and started a conversation about diesel dressed up as Titanium. This gent, being kind, basically stated strange-looking but hella knowledgeable. At that point, it didn't matter what I looked like, but the facts of my knowledge to help this old man fix up his 7.3L Ford floored him. I told him about his rear tires being over-inflated and how to fix it with my math formula. I showed him my phone from the website. Then I told him to consider replacing injectors because 176k miles is a bit long on factory injectors. He was very thankful I just happened to be there to give him info, This is why I don't care if I'm dressed up as Titanium, Mopar1973Man, or just Michael Nelson. I steal the show anywhere I go, any way I'm dressed. Titanium is my favorite way to be in public. No matter where I go, I'm always finding someone to just wants to ask why. Now, when the cancer story comes forward and the fact I lost all the hair on my head and found a way to enjoy life yet with cancer and still look good. Remember this is why I will be getting married soon. I met in the West Portico building in Meridian, ID, and had the luck of meeting her twice It was Suzanna who asked me for my phone number. There are just too many great things that come from my wonderful makeup work and the person I am! Would you stop doing this? Or would you be the one like me who wants to see how far down the rabbit hole this goes?

-

Are you stopping?

I had other running around to do today. By the time I came back home, I only had a few hours of daylight left before the shadows of the mountain start casting on the valley floor. I managed to get the filler neck installed and managed to cut the unleaded neck out to fit the diesel fuel nozzle at a fuel station. I was getting sore from lying on the ground to deal with that, so I shifted over to dealing with the brake light issue. Now I got power past the brake light switch still not making it to the taillights, so I've got more testing with a test light to find the issue. I'm so close to having this truck running so I can deal with repairing Beast that is nearly 500k miles and having serious oil leaks around the crankshaft seals, both front and rear.

-

Brake Light issue

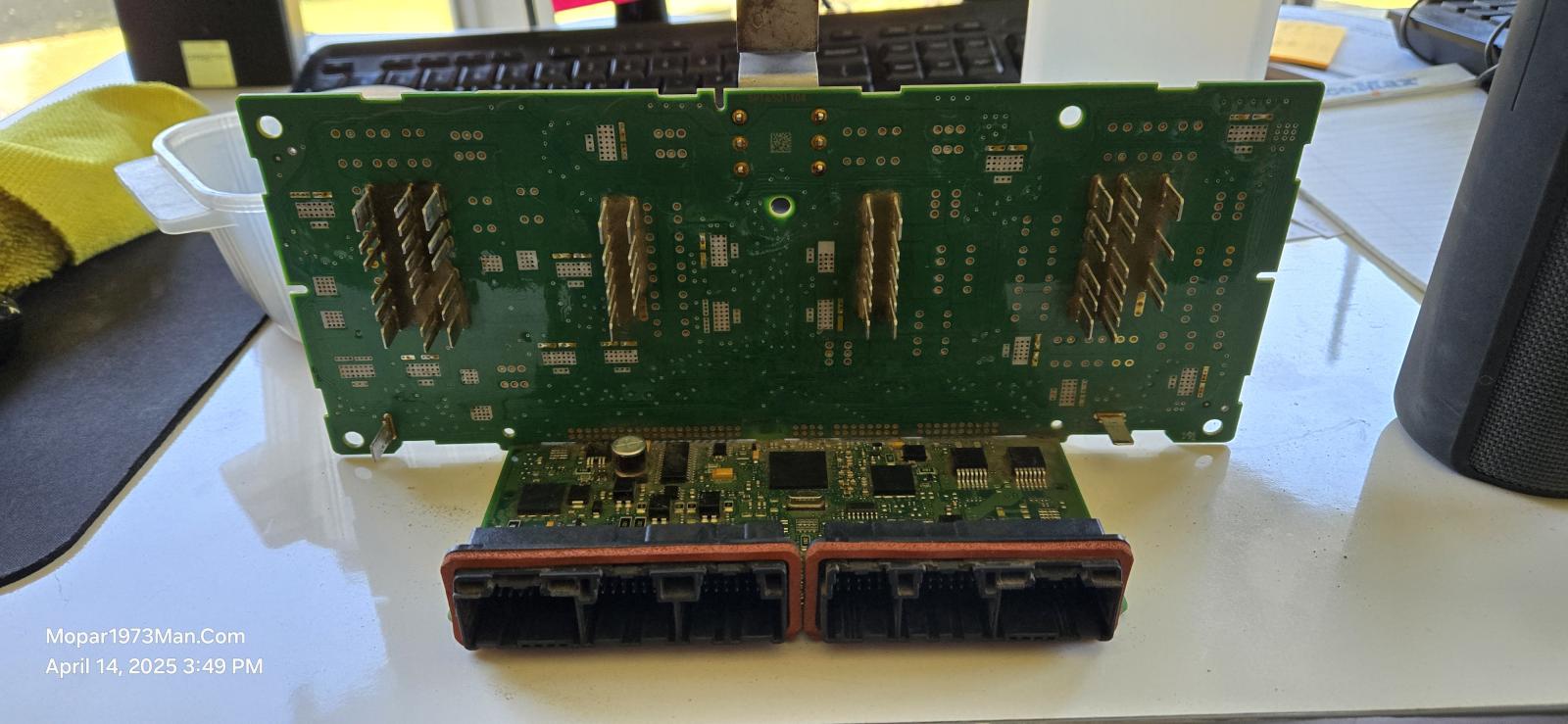

Update. I pulled the TIPM and cleaned off the board, looking for a bad circuit board tracer or burn. Nope. I cleaned the TIPM up and then reassembled and hooked it back up. I'm not sure why I didn't have power at the fuses, but now I do. Bad connection maybe? Now I'm tracing down the wiring hit the brake light switch and then attempted to check brake lights. Nope, Nothing yet. Now I pulled the brake light switch so the lights would be active. I checked at the pins power coming in and then the pin pressed in the light goes off. Normal working. Just to let you see the inside of a 2006 brake light switch internals. Now I'm at the connector at the fender checking for power for the brake lights, but I'm giving in today.

-

1999 Dodge Grand Caravan - Minnie - Electrical weirdness

Sadly Mark took care of it for me. The blower is under the passenger side but covered with another cover.

-

Brake Light issue

I need a bit of help, possibly for the 3rd Gen TIPM, which on fuse 26 is my fuse for the brake lights. The fuse is good. Now with a test light I have zero power. If there is no power at the fuse then there must be a burnt tracer in the TIPM I'm figuring.

-

20250413_133900.jpg

From the album: Thor - 2006 Dodge Ram 3500

-

20250413_135020.jpg

From the album: Thor - 2006 Dodge Ram 3500

-

20250413_120527.jpg

From the album: Thor - 2006 Dodge Ram 3500

-

20250413_120511.jpg

From the album: Thor - 2006 Dodge Ram 3500

-

20250413_111727.jpg

From the album: Thor - 2006 Dodge Ram 3500

-

20250413_110537.jpg

From the album: Thor - 2006 Dodge Ram 3500

-

20250413_110352.jpg

From the album: Thor - 2006 Dodge Ram 3500