Everything posted by Mopar1973Man

-

Big change in my life...

1st surgery went good. Doctor was happy on how I healed. So for the 2nd surgery the doctor scrapped my bladder and it to pathology. But my right ureter is plugged up. Not sure if it scar tissue it tumor. Either way I'm going in for a. 3rd surgery to drain my right kidney. Then later on go back in for a 4th surgery to put the stent in.

-

Choosing The Right Fuel Lift Pump For My Needs

Because the return port in the VP44 is too small for higher pressure and could possibly push the front seal out. Rare but has happened. Return is on the left.

-

Choosing The Right Fuel Lift Pump For My Needs

Brass timing sleeve to steel timing sleeve. Rubber diaphragm to steel plate.

-

Big change in my life...

Survived the second round. Still kind of out of it.

-

Choosing The Right Fuel Lift Pump For My Needs

Interesting... I've got to ask what is the stated HFRR score for that fuel.

-

Front end

You want big wheels and tires you need 4.10 gears at the minimum. Final gear ratio to the ground should be 3.55 or greater.

-

New Exhaust

Both... Any grade makes it drone right at 60 to 65 MPH. Now stand on the throttle passing someone it screams. Muffler really only keeps it quiet in the city more so and flat cruise state.

-

Choosing The Right Fuel Lift Pump For My Needs

- What fluid for the 47re Trans?

Transmission fluid and the filter is every 30,000 miles. No comment...- Choosing The Right Fuel Lift Pump For My Needs

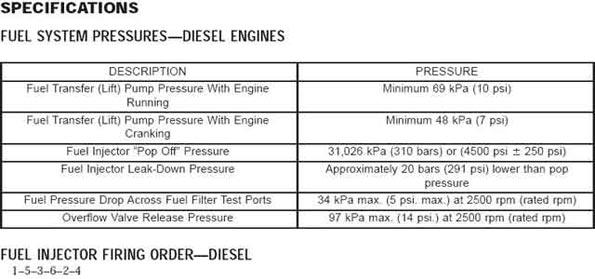

Biggest factor your up north in the cold country. I would suggest an AirDog and do some creative mounting. As for the FASS it's very very large and tends to hang in the damage path of the front tires. The pump needs to be strong enough to maintain 14 to 20 PSI at all times including WOT. With Canada cold you need a fuel system that can be tuck away from snow and ice and out of the blowing wind. This is a good layout. Protected by the transfer case and the skid plate. I've been to -40*C (-40*F) never gelled once. Since this picture I've moved my fuel lines inside the frame. Better protection from blowing cold. This is a bad layout and more prone to gelling up.- Daves $100 garage

Now head over to HF grab a bag of shop rags. You'll need it. When the head is pulled off you'll be laying fresh clean shop rags over the exposed block. When the new head comes to make sure that all cylinders are clean and no debris in the cylinders before placing the head. That is one heavy chunk of cast iron.- Big change in my life...

Yeah, I know its illegal in Idaho but I've been treating my cancer with cannabis. I'm leaning on stronger CBD sided herb than the THC side. Cancers tend to respond better with an equal amount of both CBD and THC strains. This why I tend to favor the smoke / vape side more so. It's not the filtered down industrial hemp that CBD is typically made from. From just what I've done so far I've managed to beat two surgeries and healed my right kidney completely. Here is a cannabis wheel...- New Exhaust

Even my 4-inch muffled Diamond Eye drones really good by 15 PSI of boost. By 40 PSI she is screaming out that 5-inch tip. Loud!- What fluid for the 47re Trans?

For factory 47RE I would stick to the ATF+4. Modified transmissions tend to be able to tolerate the ATF+3 because of the different clutch material that some rebuilders use. I remember @Dynamic telling me about the fluid differences.- Fass install Question

Try getting down to the empty mark. I've been down below the 1/8 tank with the low fuel light on. I'm like you, I don't like being below 1/2 tank either because of the distance I do travel. Quadzilla is very handy that my fuel gauge is rather strange. The half mark is true 17.5 gallons to fill. Then 3 gallons later I drop from 1/2 to 1/4 tank. Even as its falling below 1/4 I've still got 10 gallons. Instead of panic time, I was very relaxed knowing that I had plenty of fuel yet. When I did fill up I was only off by 0.3 gallons.- can i use v10 tank on 12v?

https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/part-number-lookup-tool-2nd-gen-24v/- New Exhaust

4 inch exhaust with muffler. Still fairly loud in the cab with drone. Mostly climbing grades. My 3 inch was much quieter. As for EGT I've had no change really from 3 to 4. More change with the Quadzilla for EGT.- Big change in my life...

My current pile is working on 4th gen articles. Right working my way through OBDII error codes.- Daves $100 garage

- Help broken axle U-joint

A good suggestion... That all suspension and u-joints that are pressed just get replaced every 100k miles. If anything makes it as far as ours at 350k to 400k miles it's just totally insane to get the rusted parts or of axles and shafts. I'd rather change out a good joint at 100k miles easily than fight a rusted u-joint that been in place for 17 years of rust. UGH!- Big change in my life...

Actually... I started in 2004. The original web address was http://www.frontiernet.net/~mopar1973man which was the very start of the website which was nothing more than my personal notes and tidbits from what I learned. I started at Diesel Truck Resource got booted out because of having my own website. Then moved to CF and still hold a contract with them to this day. I'm permitted to post article pages but no forum links. I've got a lifetime premium membership. Then M73M domain was purchased back in October 4, of 2007 and the M73M continued to grow. Then M73M grew so much it became a full-time job just keeping the site rolling. I'm still debugging the server and fixing weird issues. Eventually, I'll get this to settle down and then move back to building articles.- Big change in my life...

Nope. 1970... Now you are going to ask why 1973? That was the first car I own was a 1973 Dodge Charger SE. The web name came from my original email of moparman@cyberhighway.net this internet company failed and we switched to Frontier. When I did the username moparman was gone. So I used mopar1973man@frontiernet.net being it was available. Which both of these emails are now gone and now using mnelson@mopar1973man.com Yeah, I know it. Wake up in the morning feeling like I've been beaten with an ugly stick. Then take a hot shower to loosen my lower back muscles and then I'm good for the day. Now with the 20-mile bicycle ride that got the entire lower half of my body sore. Oh well, I'll keep pushing. I'm actually enjoying the bicycle rides and traveling that way. Nice way to relax once in a while.- Big change in my life...

Wow! @Russ Roth and @015point9 ... Heck of a story there Russ... That is sad to hear you listed as terminal. Hopefully the Good Lord willing that this healed in his own way. Never thought I could get cancer this soon in life either but I've been told already that there is a 95% survival rate with bladder cancer. My next surgery is to double check I'm good. Got my fingers crossed. @015point9 I've got a friend in Riggins with a wife with a brain tumor as well. She is doing good right now and going to live life to the fullest. Had some other medical issues but she keeps springing back. She is even younger than I am. I just keep marching forward the best I can... I might not be fast but I'm still moving forward.- Homemade bumper

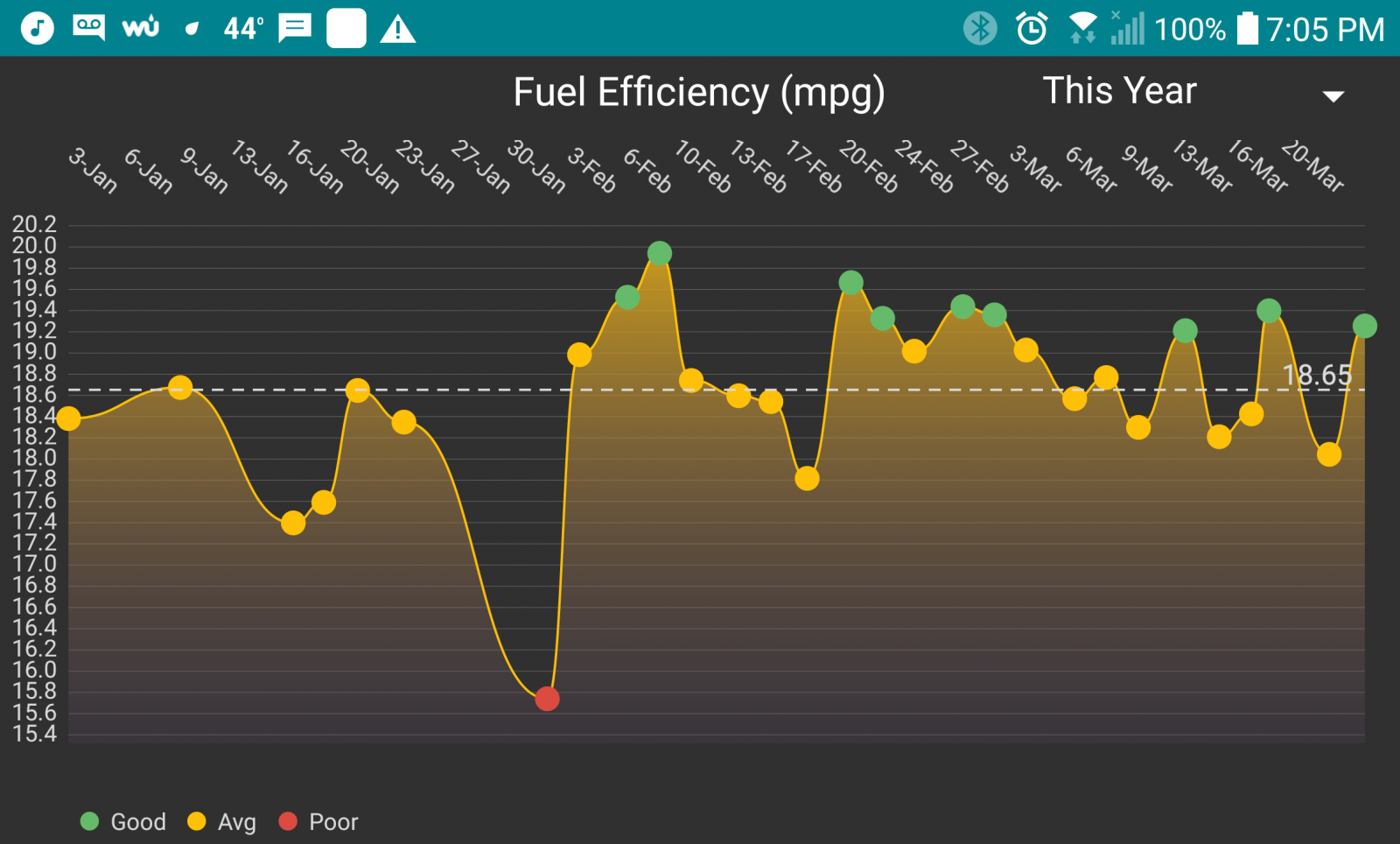

Kind of figured. They get heavy really quick. I like the bumper as well just know that there is that weight factor. I've seen plenty I'd love to have on my truck just too heavy for my blood. My problem is I haul heavy in the summertime hauling firewood and my RV. So far with my lastest tune I've managed a solid 18 MPG at 80 MPH on the I-84 on the last weekends tank. Then my 65 MPH is netting right at 19.6 MPG on the last tank. My 55 MPH shows to be in the 24-25 MPG mark range on Quadzilla which is very close to right.- What fluid for the 47re Trans?

No. You got to use the ATF+4. The friction modifier is required for the clutches. ATF+3 doesn't have any friction modifier. - What fluid for the 47re Trans?