Everything posted by Mopar1973Man

-

My Personal Opinion

Well, I'm still here and doing good. This was a try at mostly blue makeup my eyes are a two-tone blue and only black was used on the waterline of my lower eyelid. Now there was a stopover a Walmart. I was picking up supplies for myself personal and also medical stuff I use. Believe it or not, a guy from NAPA caught me in Walmart. Yup, he called me out which is fine but gave an update on the surgery I was doing. He was glad to see I was doing good and no I'm not shy about going out and seeing people dressed up in my Emo Goth mode. People around do care and want to know how I'm doing. One of my stops is the Council, ID NAPA store, and say "Hi" to the guys that supply me parts for all my jobs in the past. I've had some bleeding issues with my left bag. I made the appointment to have both bags and plumbing all changed again into my back. This time I made the trip in makeup and my light blue hair. Boy, I was so happy I did. The lucky stroke was the nurse I talked to on the phone to set up the appointment was the very same one I got when I showed up. He loved the look. While I was getting ready for surgery my doctor showed up and I explained how the ports in my back were very sore. My doctor said he'll upgrade my stitches on both ports to silk the replace fishing line-looking stuff. That in itself feels much better in my back. The surgery was a total of 15 minutes again I did it with no anesthesia again. I don't feel anything in my back as he removes but inserting the new tube it feels like my guts are moving in front of my belly. I was in and fresh bags and tubing. It's like from the center line of my hips to the back I'm more or less numb and don't feel anything. Now from that center line forward, I can feel pain when feel disconnected being the rear nerves are more or less shot. I was treated like a king during my whole time in the hospital. After my surgery, I was released and was hungry. I stopped over to Golden Coral for a buffet-style restaurant to eat. While I was there the hostess that was working my section was making sure my drink never got to 1/2 full glass and making sure I was not running out of plates. She hung around and again people were curious. Very cool hostess and she made my time there simple and well taken care of. Personal Note: Yes my makeup work and appearance do make a huge difference in the way people treat me. Even with the shirt I was wearing which states, "Fun Fact: I Don't Care." Show off how my makeup artistry affects people. This is the very next day I get a text message saying my meds are ready in McCall ID. Mark and I ran up to McCall to do some shopping and get supplies. Mark headed into the store before me as I was on a phone call and needed to finish first. As I came into the store this gal was kind of dancing to rhythm in her head as she was heading towards me. She spotted me and danced up to me and said I looked like I needed a hug. Then the comments about my appearance. She asked if my hair was a wig or not and she wanted to try it on and get a picture. She was giggling like a schoolgirl and enjoying the moment. I got my wig back and asked for my photo now. I kind of cheated on makeup that day being I was still a bit sore from the surgery and the tubes still moving inside. I did basic black and no color. I darken my eye sockets into my nose more so. Still, a shock to have a random woman just walk up hug me, and want to just be part of my fun moments. Even with the shirt I was wearing that day, you can't see, "Don't Like Me? F__k Off Problem Solved"

-

Cummins Tappet Cover Gasket Replacement

I've not had to replace the bolts in any of the gasket jobs I've done. Just do not use any sealants on the gasket it's not required.

-

98 12 valve cummins no bus, need help please

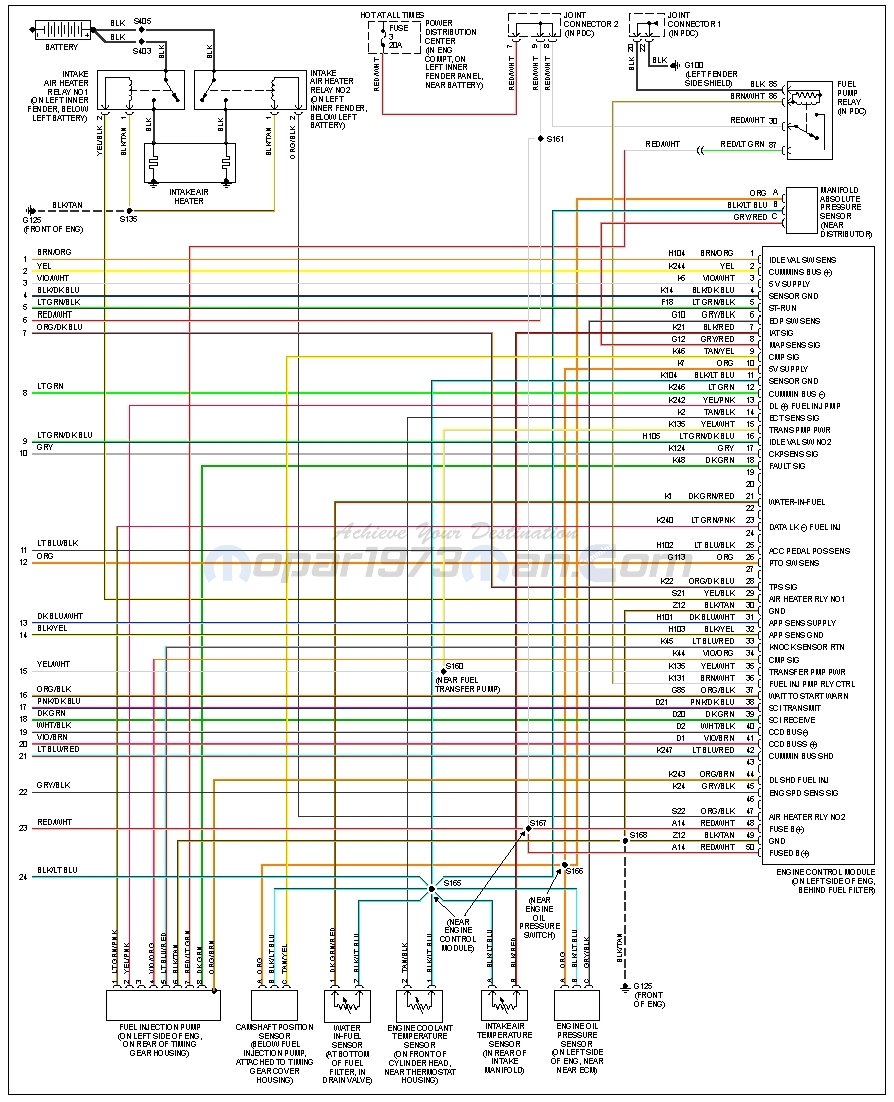

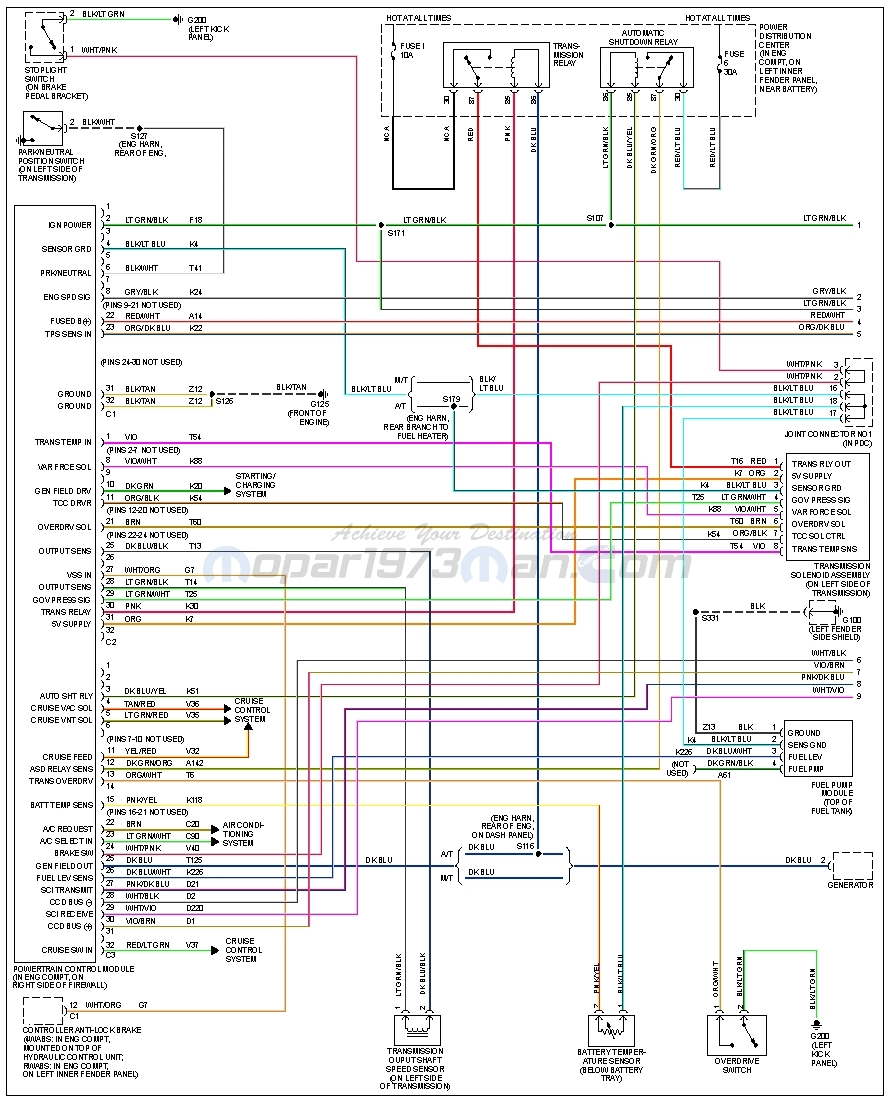

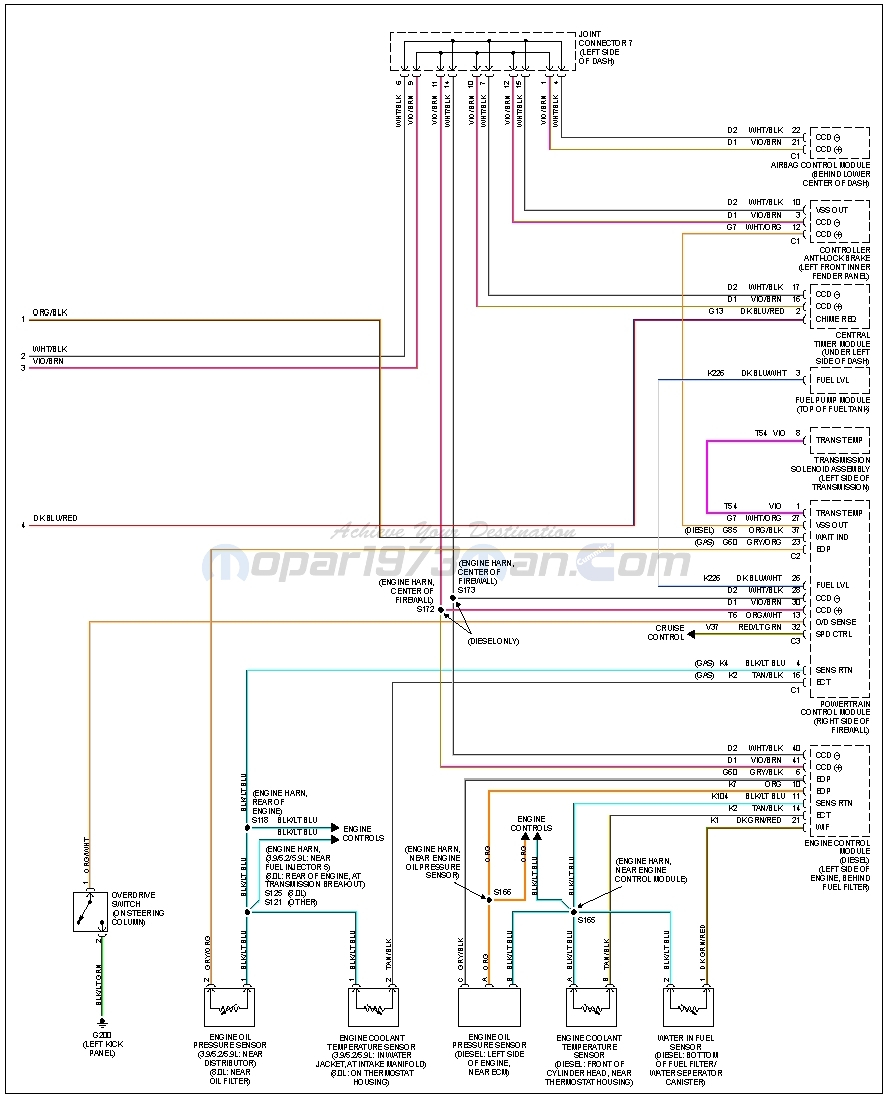

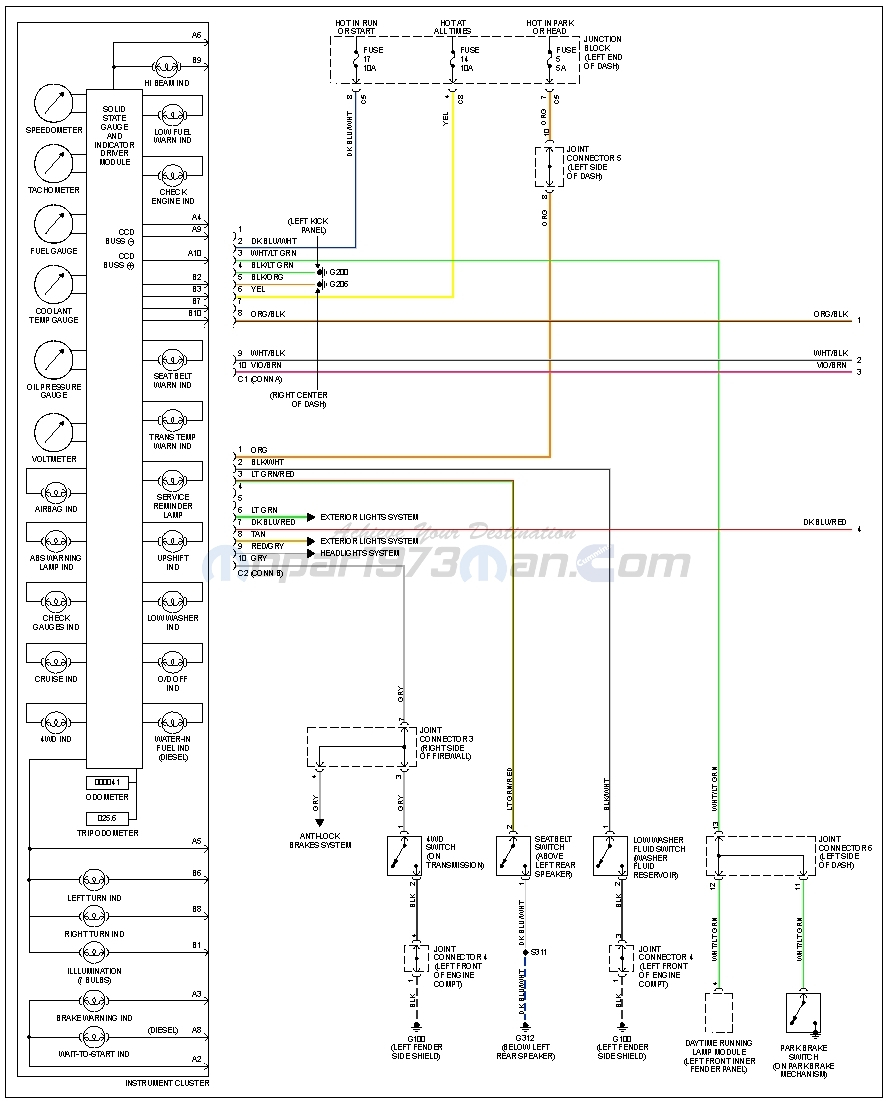

PCM controls the Overdrive light. ECM controls Wait To Start light. This is the only light that the ECM is in direct control of that is wired directly to the light. P0381 code would be present if there is no circuit or light issue for the Wait To Start. Only way to test either ECM and PCM is to send the modules to @Auto Computer Specialist and let them bench test the modules for you. Look at pin 37 is Wait To Start. Look at C2 pin 14 which is the Overdrive switch Cluster wiring... You can see the O/D switch. Orange/black pin 8 is your wait to stat from the ECM.

-

My Personal Opinion

I wanted to share my next idea for my makeup work. I've already used this one for my chemo treatment and my chemo staff loved the look. I'm trying to keep people on their toes being so far I'm enjoying blowing people's minds. Like last night I went to BBQ with a few friends in Riggins ID and was dressed up in my Blcak and Blue hair but I'm playing with other makeup concepts and so far people don't even know it's me any longer. Few people now had to ask Jake who I was and then when my cover was blown it was funny because they couldn't believe it was me the Mopar1973Man decked out in Emo Goth looks. Newest concept... Being I'm still dealing with my cancer. It's nice to be dressed up and enjoy my time being out and about sharing my makeup and Emo Goth looks and just forget about the fact I'm constantly hurting with these ports in my back and dealing with cancer. The fun of putting a smile on other's faces and then also putting a smile on me even for a short time. You all have to remember I'm limited on what I can do here to be productive right now and can't work on Cummins diesels. This has been a huge way for me to enjoy the time that I'm hanging out till my big surgery where I'll lose my bladder and prostate. Did you know my sexual organ (one eye) will no longer function? Yup just consider the fact I'll never enjoy sex again and I'll never piss like a man again. So again people might think I'm off the wall... I don't care. Why? What if this was my last chance to enjoy life and only could live to June? What would you be willing to do to enjoy life? Yeah I know I'm not going to die anytime soon but it makes you think. Consider my position that sexual I'll no longer function any longer. Just consider that every day I get up alone and really can't do anything. So you start looking to interact with others just to have some enjoyment. Hence why I'm enjoying some makeup artistry and just getting my feet wet and have to learn a lot very quickly.

-

98 12 valve cummins no bus, need help please

2.49 and 2.51 respectively after all communication is done.

-

Pilothouse/RAM3500 build

Truth...

-

My Personal Opinion

I loved the fact when I was leaving and I stopped out front to make sure everything was is check before I leave. I had all the receptionists laughing as I left the building. My case worker loves the energy I bring to the build while I'm there. Amount of people wanting to just ask What's your story. Oh I did find the photos.

-

My Personal Opinion

Good morning gang... Chemo run number two over. Being I had a chat with my pharmacist and knew what is was dealing with I've be taking care of my meds on a tight schedule. This morning I got up and feeling super good. No nausea and my energy is good. I do have some medical things to sort out with my doctor.i hoping for my phone call this morning so I can get things checked out. I feel good enough to actually sit down and do code work on the server. First let me get my doctor visit handled and if im still on track I'm going to get busy working tomorrow. I've got a story on my chemo visit. My IV nurse requested for my light blue wig and metallic blue eye shadow makeup. Sadly I got there and Rusti wasn't in being her kiddo was sick. Strange enough the hospital Chaplin walked in and seen me and sat down and asked What's my story? Well it went all over from past, present and future talks. He was giving me props on my look and liked the light blue hair. He hung out till my chemo was done. Shocked him to tell him I'm a internationally known Cummins mechanic and showing off the website. Like I told him even spiritually I'm in order and explained how thankful I am for all the medical staff has stepped up for my needs and getting excellent care.

-

98 12 valve cummins no bus, need help please

Biggest thing is to see if you got the bias voltage of 2.49 and 2.51 on the bus. Then hunt down why the bus might have a voltage offset be it 0V, 5V or 12V either a short to power or short to ground. Could be a open circuit. I'd suggest getting in contact with our Vendor @Auto Computer Specialist and ask some question to give more clues.

-

Pilothouse/RAM3500 build

Yeah I get it. I'm on the other side dealing with my limitations too (money & health wise). I know this has been a super long running project. Hopefully I'll be able to build my project ride after my cancer treatment. Still planning on building a C Body Mopar on a 2nd gen frame that will have also a 6BT Cummins. Just gotta take care of me first then I'll most likely start next year.

-

98 12 valve cummins no bus, need help please

Speed signal comes from the ABS computer then sent typically to the cluster on the CCD bus.

-

98 12 valve cummins no bus, need help please

here is my CCD network article to read over...

-

Pilothouse/RAM3500 build

Some day we might see it move? I'm dying to see it roll.

-

98 12 valve cummins no bus, need help please

Everyone runs from electronics. That is why I can reach 30 MPG. Which is better than any 12V mechanical can do. Even 24V p-pump conversion I can beat that too. Electronics it what makes it possibly for some of the abilities of these engines. There is a reason carburetor vehicles have disappeared being they could keep up with efficiency. Then just understand even today most all gasoline engines are only 20% to 25% efficiency then look all have catalytic converter because there is that much sunburnt fuel in the exhaust. Diesels without smoke can do well in the 30% to 40% efficiency. The fuel has more BTUs per gallon. No air/fuel ratio. Direct injected and compression ignition.

-

98 12 valve cummins no bus, need help please

If you hung up give me a call. My number is in the contact us link at the bottom of any page.

-

98 12 valve cummins no bus, need help please

Just keep in mind the most this does is a fresh reset. Disconnecting the batteries will not clear error codes. Do make sure you have done your repairs first. I know both ECM and PCM will reboot fully if the ignition is off more than 10 seconds. I also know even the ECM, PCM and cluster are hooked to battery power so it might have some merit but again make sure you get the bus working again.

-

98 12 valve cummins no bus, need help please

Double check all your fuses with a ohm meter make sure you getting your power up again. There are a fuse under the hood in the PDC and then the fuse in the end of the dash. You can look at the CCD Bus article in the 24V section it will help you to understand bus voltage and understand how it works. As far as I know the cluster sets the bus voltage so you might have to send the cluster in for repairs. There is Module Masters right here in Moscow ID which can repair your cluster if it's found damaged.

-

DIY/AM Fuel Filter Housing

I'm curious what the connections to the filter are for plumbing? Hopefully something we can adapt AirDog / FASS

-

DIY/AM Fuel Filter Housing

If you got the skill go for it. That looks like it could be retro fitted to a 24V.

-

My Personal Opinion

I know I've been quiet. Chemo is pretty harsh I'm struggling with nausea and weakness. I'll make it but I'll admit it is rough. My Chemo crew are all great people. I've got a whole crew like dietitian, pharmacist, IV nurse, social worker, etc. All there for me and really helpful people making my treatments the best I can. I'll admit I was compliments about my looks, and the energy I bought to the room. My IV nurse was surprised on how much people wanted to talk to me. My pharmacist was surprised to listen in on my Cummins phone calls helping another member. Social worker was shocked on my appearance because it changed and she loved it. I'm taken care of very well by my crew. Yeah I'll say Chemo is rough being nauseated and weak aren't fun but I'll do it and get it done.

-

New Battery Cables

Like my solar battery setup the cables are all soldered and crimped.

-

New Battery Cables

Circuit breaker or fuse 150A. I prefer the breaker being it can be reset in the field but if there is a blown fuse better have spares and these can be spendy. New cables will be nice. Just wondering is the ends soldered or just crimped?

-

New Battery Cables

Got to do the charge lead too.

-

New Battery Cables

Absolutely... A must for keeping these trucks going properly.

-

New Battery Cables

Simple fix go out on Amazon and order military style terminals and a set of copper lugs. I prefer soldering my lugs being it seals the copper from corrosion. Then you just need to change terminals when damaged again. Cables rarely go bad unless the corrosion is deep into the strands which is why I like soldering my lugs. Stops that from happening. Dumb question? What are the only 2 materials that can contain sulphuric acid? One is glass and the other is plastic. What is plastic made from? OIL. Cover you battery terminals with engine oil they will never rot again. Now seeing the ground lead where you scrubbed all the paint back your going to start rusting I highly suggest to repaint those spots being it will rust and create weak ground connection. I would paint the metal and let it dry then shot the bolt and terminal back on.