Everything posted by Mopar1973Man

-

New 2nd Gen owner

Figures... @IBMobile would post his photos he got of me. We all had a good time. Yeah even I've got a wild side.

-

New 2nd Gen owner

Yeah I'm sure you will post the pictures of me wearing the blue and black.

-

Weird Defueling Issue, any advice can help.

Basically in the nutshell you have +5V signal from the ECM and the thermistor will vary the resistance the higher the voltage the higher in temperature. Lower resistance would give more ground lowering the voltage making the temperature read lower.

-

New 2nd Gen owner

Thank you for the kind comments... We treat all members like family. I make it a point to call some of the common members and chat with them at least monthly if I can. Heck I've even gone camping with some of the members too. Done work on some of the members in person. So yeah you are now part of our family and will do what we can to help you out with your truck. Heck like @JAG1 and @IBMobile I just went camping with them in April last year. Should be in the forum I'll dig it up later.

-

Weird Defueling Issue, any advice can help.

I think 56k ohm is 123*F if I recall correctly. So going higher in resistance from there should get you closer to that temp.

-

Biden & Trump

I've been hunting for that video. It was leaked from congress and they were talking about transition from Biden to Trump for a 2nd term shortly. Might of been deleted.

-

Biden & Trump

I found a leaked video of the US government stating that Trump will be transitioning Biden out and Donald Trump back in for a 2nd term. When I find the video again I'll make sure I post it for you all.

-

Headstud install

I'm running 25* BTDC at 2,000 RPMs currently with my tune and head studs. But the trick is my high timing will only occur when the boost is below 5 PSI. Typical at 55 MPH is 0 to 1 PSI boost and then 65 MPH is 2 to 3 PSI boost. High timing with high boost will for sure blow the head gasket... Make sure the timing retards when engine load rises...

-

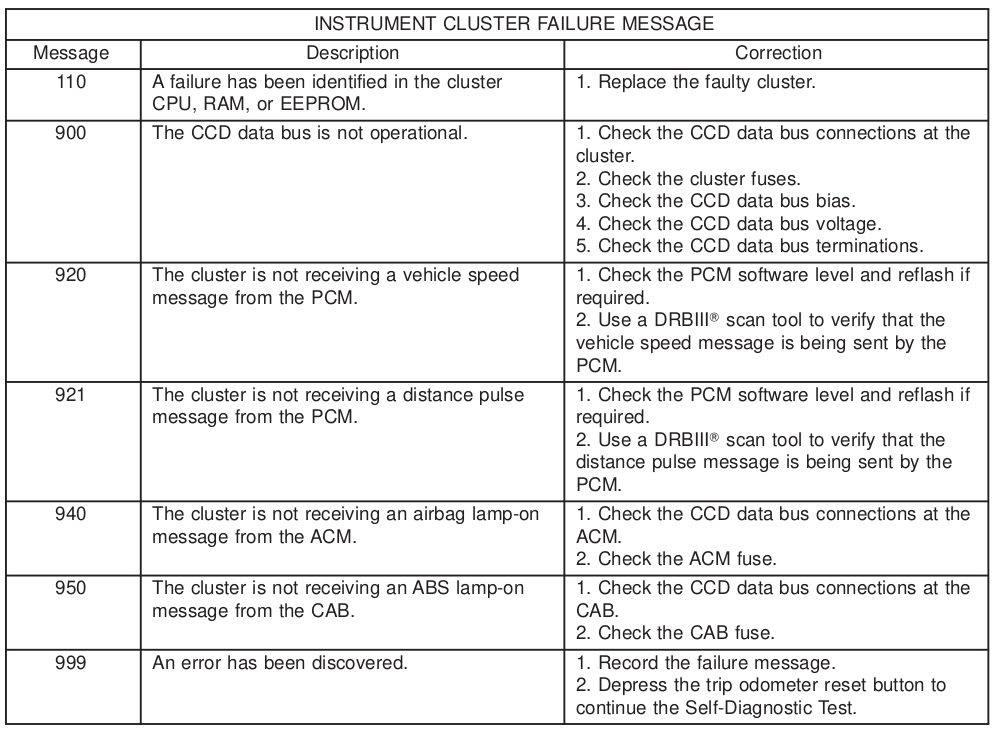

p1698 code NoBuss

Again back to the PCM and verify the software on the PCM is correct. PCM is what creates the CCD network bus. Then the gauge cluster sets the CCD Network voltage to 2.49 and 2.51 volts. Which you can measure at the OBDII port with a DVM but make sure to wait several minutes for all modules to stop talking.

-

p1698 code NoBuss

Anywhere really the favorite I like is the OBDLink MX series. https://www.obdlink.com/products/obdlink-mxp/ Then you can monitor live data and also read error codes with your cell phone or mobile device.

-

Headstud install

Last head gasket I went to 135 foot/pounds of torque. Even though the max torque ARP calls for is 120 foot/pounds.

-

p1698 code NoBuss

-

New 2nd Gen owner

Welcome to the Family... I'd be glad to teach you all I know. Just got to ask questions. There is no such thing a stupid or dumb questions...

-

Headstud install

Floor jack on the floor passenger side then place the 2x6 board under the cowl on the passenger side. Then just jack up the cab about 1/2 inch and the clearance will be enough to slip that stud in. The body rubber is just compressing.

-

Weird Defueling Issue, any advice can help.

Any other error codes present too? P0216 code will create timing issues. Depending on if it the timing is full retard or full advanced. I've had my last injection pump seize the timing piston at full retard and power is greatly reduced and hard knocking. Full retard will still run but the power is greatly reduced from the lack of timing. As stated by the Dodge FSM for the P0216 code. Not uncommon for a timing piston to seize up and stick. This is typically from low lubricity fuels and excessive use of cetane boosters and anti-gel. This is where the 2 cycle oil theory comes from. It wouldn't hurt to send to Auto Computer Specialist and have it reflashed to stock values to verify.

-

Headstud install

Easy I used a floor jack and a 2x6 board. I placed the board under the cowl and jack it up about 1/2 inch and the stud fell in on its own.

-

p1698 code NoBuss

Yeah I would check power and grounds of the PCM. Then I would pull the PCM and send it to Auto Computer Specialist being the PCM creates the CCD network and supplies gauge data. Cluster is what creates the Bias Voltage for the CCD so it won't hurt to test the cluster by holding the trip button turn the key on and watch for CHEC to show and release. Any codes please list them.

-

Grid Heater Light and Chime on 3rd Gen

Yup just found it on the internet... SB18-006-12.pdf

-

Grid Heater Light and Chime on 3rd Gen

Yup. I've got a call in for returning the injectors and will be pulling the injectors for testing. I'll most likely get started on that tomorrow. I just checked both my 2005 FSM and my 2006 FSM and neither book list the error code.

-

Squirrels Got Me Good

Yeah... Out here truck owners buy blocks of mice poison and tie wire the poison blocks under the hood. This is why I mention it. Just attracting mice under the hood...

-

Grid Heater Light and Chime on 3rd Gen

Yeah I've got to add that error codes to the list on 3rd gen since when I just looked it was missing. Strange enough my scan tool shows as a Grid Heater Performance on that code.

-

Grid Heater Light and Chime on 3rd Gen

IIRC it was P1222...

-

replacement homemade VP44 & ECU project update.

Nothing wrong with the PSG circuits. The biggest problem is stock pulls from the hot fuel in the sender basket then a lot of people went back to draw straw in the basket which is a very poor idea. Mine is drawing forward of the sender basket which is typically cooler fuel. I've never had a PSG failure yet. (P1688 and P1689)

-

Grid Heater Light and Chime on 3rd Gen

Just a heads up if you have a 3rd Gen and happen to have a weak connection or on connection on the grid heater power wire it can and will pop the grid heater light and chime as well just like a fuel rail issue. If you pop the hood and don't see any fuel leaks then proceed to get to home or safe place. Get your code reader out and check I'm going to bet there is a code for grid heater performance. Once the problem is fixed and the code cleared the light will remain off. In my case I've unhooked it back in the summer time be I was having a charge issue for the batteries and forgot it was unhooked. No hard starts. Funny part is the light tripped after 30 miles of driving and the engine was at full operation temperature which was weird it trip the grid heater. That makes me ask does the ECM command grid heat while you drive as well?

-

Squirrels Got Me Good

You gotta ask what was inside his garage that was attracting the squirrel to chew on the seal? People don't think about what the animal is looking for the smell of food possibly? Warm place to be? If you remove the smell of food and warm animals typically don't work as hard trying to get in to what ever being a garage or a vehicle.