Everything posted by Ironforger

-

Average mpg for basically stock truck

@Me78569 , Can you describe what the "proper tuning" details should be if I get 7 x 010's? I'm pretty much stock now (except for a fuel boss mech fuel pump, 4" exhaust, southbend stage 2 and BHAF). I'd like to add power mods in the future and not exactly sure what to do but this thread has helped me understand and narrow down my choices. Caveats: HO NV5600 Currently running 4.10's, may switch to 3.54's at some point. Factory tire size 235's (and I'll be keeping the 235's for a while since I just got a new set of Michelin's) Will be doing random towing - at least 10,000 lbs or more (ball or pintle hitch, not gooseneck) Not looking to spend huge $, just looking for the best bang for the buck that may work best for my current setup / factory turbo & the HO VP44 / 28 injection pump. Appreciate your recommendations. Thanks!

-

Re-wiring factory trailer harness

Thanks @towrigdually, Great idea although not sure if I'll have time to hit a junkyard. I'm considering a hopkins connector as well: https://www.carid.com/hopkins/endurance-7-rv-blade-molded-car-end-connector-with-cable-mpn-20022.html I'm customizing my service body step bumper - recessing the vehicle side 7 blade connector so there's less chance of breaking it while I'm not towing. Glad to hear your pdc fuses have the same config. How do you like that current tune you are running? pm sent

-

Re-wiring factory trailer harness

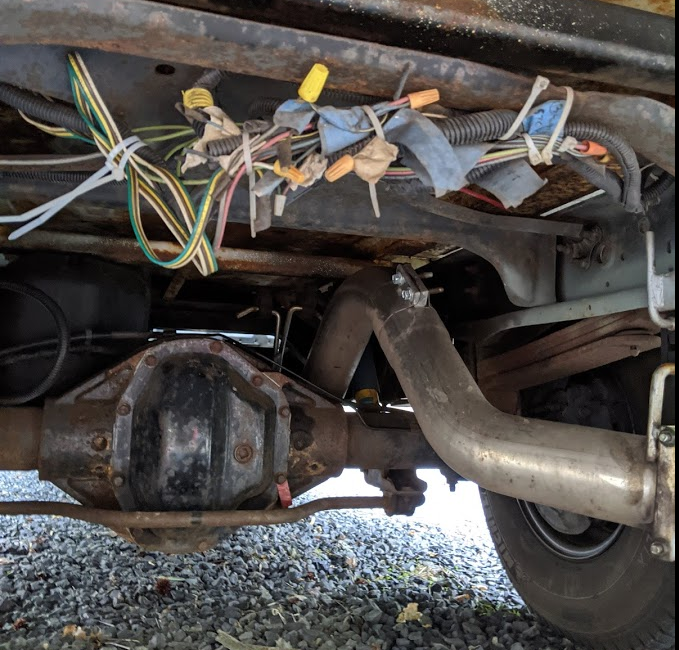

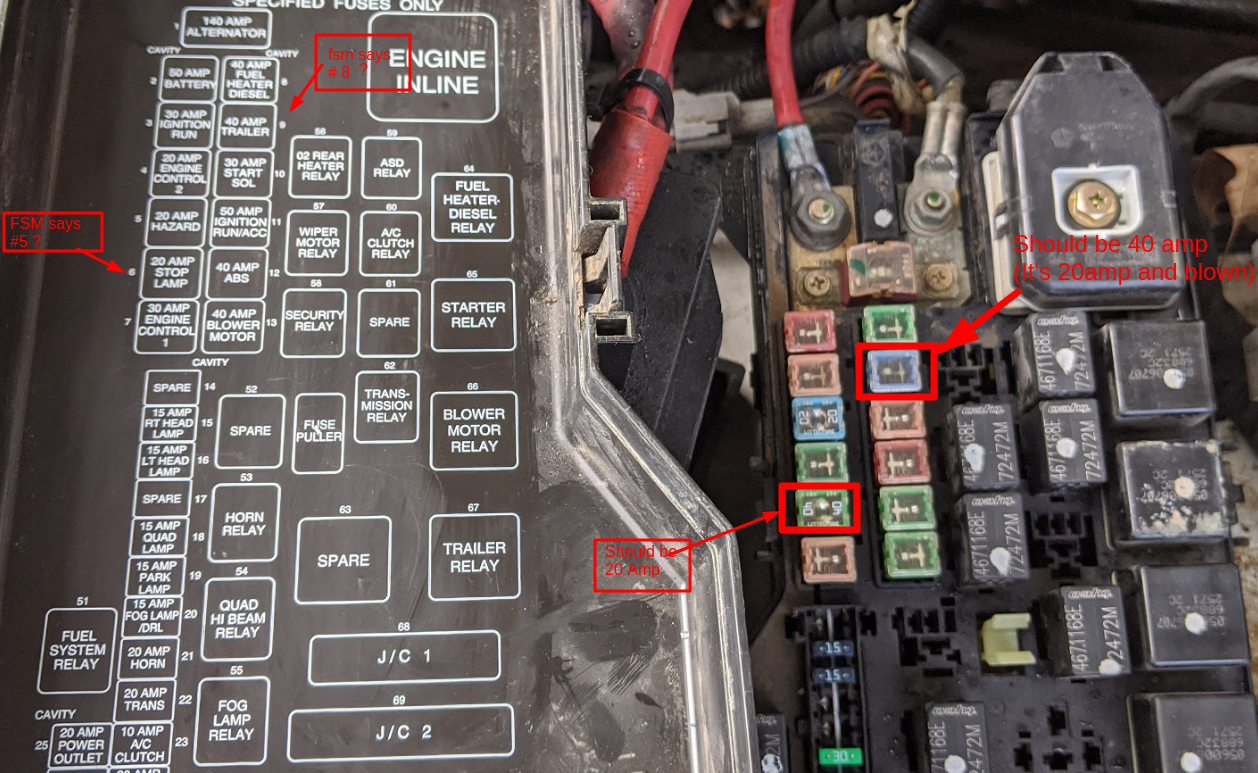

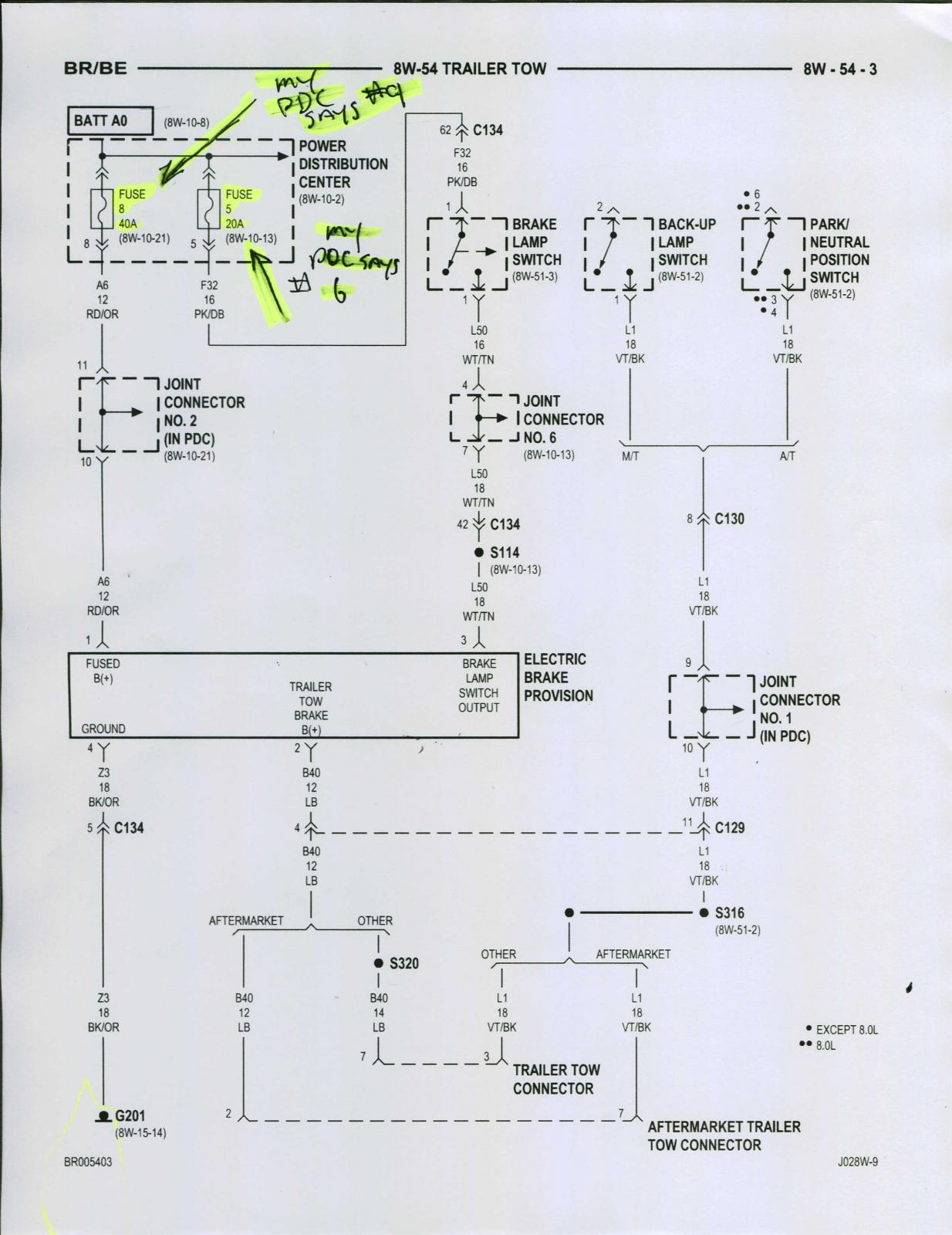

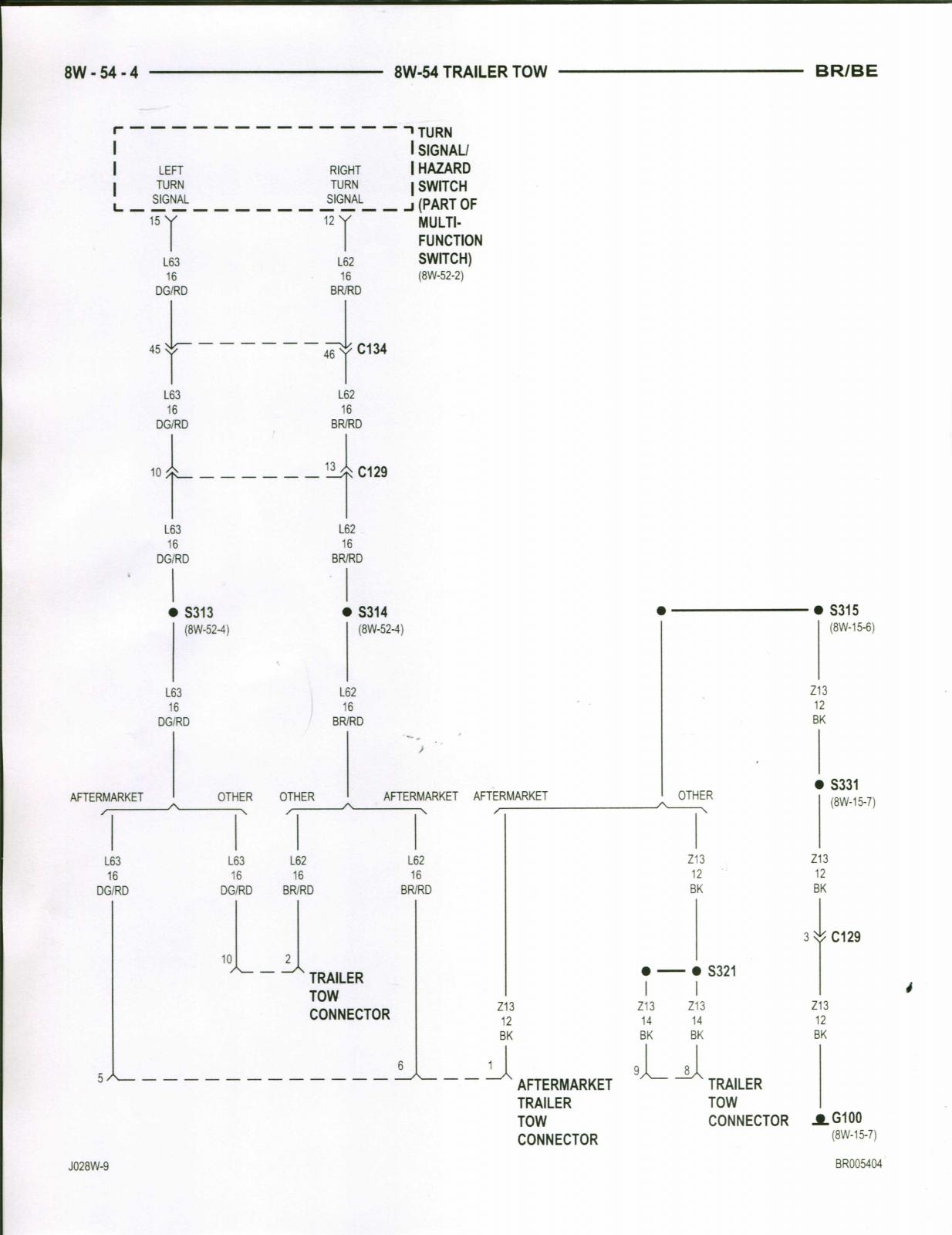

Not sure If I'll need help with this topic just yet but decided to start this thread / discussion to help me get the mind-set. Maybe this thread can help others who need to sort out the trailer wiring. Ok so when I bought my truck in 2013, it didn't have a bed or body on the back. I basically bought a truck with just a cab. Previous owner was using it as welding rig. He got a new truck and swapped the welding body onto his new truck. Unfortunately he was not so nice and he cut ALL of the wires in the back for the tail light and towing. Left me with the rats nest bunch of cut wires. I used a test light to get the basics connected for the stop, turn and tail lights and a basic 4 pin connector for a small utility trailer. Now I'm getting ready to setup wiring correctly with an aftermarket 7 pin connector. I'm getting ready to do a little more serious towing. I'll be towing a 10,000 lbs dual axle / electric brakes enclosed car trailer from New Jersey to Florida Multiple times this May and June, each trip 2000 miles round trip.. I appreciate the availability of the 2002 FSM from the mopar1973man website and found the wiring - trailer tow diagrams. This will help with identifying the wires based on color codes among the mess of cut wires. This truck has the factory trailer tow package. There is a trailer relay in the PDC. There is a brake controller under the dash which appears to be wired to and connected to the factory harness, plugged above/in front of the brake/clutch pedals. The brake controller appears dead, and upon brief investigating found a blown trailer Jcase fuses in the PDC. (Mine had a 20 amp Jcase in the trailer slot, it should be 40 amp. Also, the stop lamp had a 40amp Jcase it should be 20 amp. I'm guessing the previous guy swapped them for some unknown reason. Also, for some reason the fuse slot numbers in my PDC don't match the fuse numbers in the FSM trailer wiring diagram. Is this a common issue? Wondering if it's a typo in the FSM. Going to try to figure out these cut wires one day this week, hoping for nice weather. For starters I've at least identified the LB (Light blue) electric brake wire among the rats nest. Pictures below starting with the rats nest: The brake controller, factory or dealer installed? MY pdc. Jcase fuses are mixed up. FSM Trailer Tow wiring diagrams:

-

Vacuum Pump Rebuild

Is that gasket that came with the gould gear kit coated with neoprene? (the big 2 hole gasket that goes between the vac pump and the timing gear housing). Do yourself a favor, definitely put RTV on both sides of that gasket before you put the vac pump/power steering pump assy back on the engine. Otherwise good chance it will leak oil, especially on the side closest to the engine block.

-

Boost sensor location?

Is that because your drive to work is uphill? I installed that needle valve inline between the Tee and my fuel pressure sensor. Works great, thanks again for suggesting. Fuel pressure gauge is steady now. Caveat you were not kidding when you said it needs to be nearly closed to keep that fuel pressure gauge from bouncing!

-

Boost sensor location?

Thanks @Dieselfuture , good info. Nice to see low rpm's at highway speeds. Have you ever driven a 2nd gen NV5600 with 4.10's? I'm trying to find someone in my area with 3.54's so I can drive and see what it's like. I have a feeling I'll be wanting some power increase mods once I switch to 3.54's On another note, I ordered a 1/8npt male / female needle valve from zoro for my fuel pressure sensor. Expecting it today. I'll set it up tomorrow. Thanks again for the suggestion. https://www.zoro.com/zoro-select-needle-valve-straight-brass-18-in-6mn31/i/G2268217/

-

Installed mechanical lift pump but....

Ahhh! Thanks @Tractorman Nice to hear feedback from someone who's hammered out this issue. I found it ironic at the time since the Vendor I got the power steering pump and Vacuum pump rebuild kit from insisted not to use RTV. His actual word were "It's Neoprene coated, it won't leak" I'll take it apart when I get a change and I'll try your suggestion. Thanks again!

-

Boost sensor location?

LOL I actually googled niddle. @Dieselfuture I see you are running 3.54's. About how many rpms are you running in 6th gear at 65mph? and 5th gear at 65mph? I'm hoping to change out my 4.10's for 3.54's. Thanks

-

Boost sensor location?

Wtf is a "Niddle" valve? Do you mean a needle valve? Thanks I was wondering about that bouncing fuel gauge.

-

Boost sensor location?

Ok I finished setting up my gauges. I went with a couple of brass reducer bushings in the port as @Mopar1973Man suggested. Took a highway ride, some gauge readings as follows. Please comment if anything out of norm? Truck is pretty much stock except for a fuel boss mech fuel pump. 6speed HO 245 hp. 4.10 final drive WOT: Boost psi seemed to max out at 22psi. EGT maxed out around 1100f. I wasn't towing anything, on a highway fairly flat grade. Truck has a fairly heavy service body, which is unfortunately horribly anti-airo dynamic, pretty much akin to driving into the wind with a 4x8 flat sheet of plywood. Fuel pressure: approx 17psi at idle. Cruising at 65mph: approx 19psi? WOT fuel pressure 17-18 psi. I'd like to mention that upon letting off the throttle, the fuel pressure went above 20psi a few times, just momentarily. Trans temp was averaging between 160f - 170f. Hers is a quick you tube vid of my gauges and speedo/ tach crusing at 65mph:

-

Installed mechanical lift pump but....

I didn't have any oil leaks with my fuel boss mech pump setup, but when I set it up I had also at the same time setup a new power steering pump and I rebuilt the vacuum pump. Turns out that damn vaccum pump housing was leaking a small about, on the inside near the block where it bolts up to the back of the timing case. At the time I used a neoprene coated gasket and I was told by the vendor that no RTV/sealant was needed and it would not leak. Damn thing started leaking right away, just a little bit, enough to drip down onto the oil pan and at first I thought it was the fuel pump to oil pan mount. Still leaking to this day and eventually oil is all over the oil pan running all the way back to the trans adaptor plate. UGH! I hate oil leaks. . Haven't had a chance to fix it, pain to remove that vacuum pump / ps assy. When I do I'm going to get a new gasket and will use RTV this time, at least on the inside near the block. On another note, regarding your fuel boss setup, be aware eventually all of the parker 7212 fuel hose will need to be replaced. The other day I was setting up a push lock Tee inline on the bigline fuel feed line for my 1/8npt fuel press sending unit. I noticed the parker 7212 hose was in bad shape, cracked and dry. (I installed it in 2013). It wasn't leaking but who knows how long before it would. Pic attached. Also, when it comes time to change your parker 7212 hose, do not cut it off the push lock fittings with a razor knife. The knife will ruin the barbs on the fitting. You need to melt/burn them off. I made this youtub vid to show how to do it:

-

Boost sensor location?

Awesome @Mopar1973Man !! Perfect location. Got it! Luckily that plug wasn't too tight in there. Thanks. I never would have found that one!

-

Boost sensor location?

Hey Guys, Finally getting around to setting up my boost / egt and fuel pres / trans temp gauges. Whaddya think guys? what is the best recommended location for the boost sensor? I'll be drilling / tapping 1/8 npt so I'm hoping / wondering if the aluminum intake just before the manifold would suit. Easy to take off without worrying about drill / tap chips getting into the intake. I got all of the other sensor locals down. And yea, I know about drilling/taping the egt probe hole while the engine is running. Done that a few times on previous vehicles. Thanks!

-

Installed mechanical lift pump but....

Agree with other posts here, I think you have a very small leak somewhere. I suspect on the suction side, but still double check all fittings on the pressure side such as the Big line kit fittings & adapter for the VP-44 inlet. (Make sure you used the cummins sealing washer that came with the kit (don't over tighten)). Also, on the suction side, check the hose clamp for the factory dorman connector to the stock electric fuel pump. And yea, double check that JIC Tee that sends fuel up to your factory elec pump and the inline check valve between that Tee and the factory elec pump. (check the banjo on the elec fuel pump discharge as well) Additionally, wouldn't hurt to remove both JIC to pipe adapters from the fuel boss pump, apply thread tape or sealant (and as @JAG1 mentioned, apply tape or sealant on the male threads, away from the end so nothing foreign in ends up in your fuel system) and re-install the fittings. Also try to rule out leaks on the suction side such as where the parker hose slips on to the existing hard line from the tank. Hose clamp tight? Just for the hell of it, get a mirror and inspect that hard line all the way back to the tank. Look for any rust. The slightest pin leak or pin hole anywhere on the suction side could cause your issue. Ok so I installed the same fuel boss and big line kit on my 02 3500, no issues. However had a similar issue with a 1st gen 1990 w250 5.9 cummins I owned years ago. Same issue. Hard to start after sitting for more than 12+ hours. Kicked my ***. I finally (after about a month) found a very tiny pin hole on the suction supply line, hidden in an area up under the frame near the fuel tank. It was a small rust nodule bump, barely any fuel coming out of it, not even enough to drip, just a tiny wet spot. (and as @dripley mentioned, air shall enter easier than fuel escapes) I cut the entire line out and ran a rubber fuel hose all the way to the tank. Issue solved. I hope this helps. Keep us posted.

-

VP44 opinions

I too wonder about my VP44. I'm assuming mine is the original pump, I don't see any yellow tamper indicator paint on any of the fasteners, although the yellow void sticker is there but ripped. My truck had around 211k when I purchased it in 2013. The first thing I did was install a fuel boss mech fuel pump and big line kit. Now I'm at 232k, no pump issues so far. @Mopar1973Man mentioned expect Vp44's to last 250k average. So I guess that makes me a bit nervous if my truck has the original Vp44 Regardless I am at least certain that it's the correct VP44 for my truck HO 245 HP / 6 speed. The numbers on my VP44 pump end in 28, which means it's a multiple of 7 (14, 21 or 28) which is specific for the HO 245 HP. Which transmission do you have? If you have a chance update your truck details in your signature. Maybe check out this video to at least verify that you have the correct pump for your engine/trans. If it's not the correct pump for your engine / trans then at least you have a tell tail sign right there that it may have been changed.

-

Used Pacbrake install

Awesome. I'd be interested to see the delta T spread on that under wot uphill towing a heavy trailer. I have one egt temp probe but haven't set it up yet. @Mopar1973Man Which location would be best if I'm just setting up one egt probe?

-

Used Pacbrake install

@Dieselfuture Looks sweet! I see what looks like a temp probe in that port on the side of the exh brake. What is that line coming of the top of the exhuast manifold pre-turbo? Is that another temp probe?

-

Used Pacbrake install

Here is a real time picture of that from my 2002 3500. I sooooo want an exhaust brake! Looking forward to that day.

-

Used Pacbrake install

Awesome! You are really using that ex brake to its true potential. it's great to see what can be done with these engines when setup correctly. Incredible mountain terrain. Any stories of people getting to close to the edge of the road and rolling down the side of the mountain?

-

Used Pacbrake install

Cool video examples. Were you tapping the throttle on the 4th to 3rd downshift? Thought I heard that! Never been to Idaho. That goose creek grade & scenery looks awesome.

-

Used Pacbrake install

Great thread! Nice to know this is do-able without dropping $$. The PacBrake PRXB is on my wishlist but its expen$ive Question for you guys who are running an exhaust brake with a manual trans: Is that 3 second delay enough time to shift before the exhaust brake kicks on and slows down the engine revs? I've never driven a truck with an exhaust brake, just wondering what the dynamics are for manual shifting. I would think that you wouldn't want the exhaust brake to engage while up-shifting? Looking forward to that article from @Gregturley Can you let us know once it's published @Mopar1973Man? Thanks! Edit! Just noticed the article. My bad! thanks

-

brake main line failure

Last year I blew the front to back brake line (runs along the frame rail behind the fuel tank). Luckily I was rolling to a slow stop when it happened, and I was able to get the truck home using downshifting to slow down. Nothing to mess with. I noticed a few other rusty brake lines and decided to replace all brake lines and hoses. I got the epoxy coated brake lines from napa. I cut, , custom bent and double flared them, then spray painted again. Years ago I installed full stainless steel lines on my restored 62 Ford Falcon. Looks great, but I had to send out the lines to get double flared. I couldn't do the double flare with my brake flare kit, wouldnt work. The stainless is to tough to work with. If I had the time I'd do it again for my Dodge truck but I had to get it back up and running in a hurry.

-

Valve Stem extensions for Dually tires

I found these solid stems online, they come in 4 per pack. 1 1/2" long. Plated brass. I'm going to order today. I'll post feedback once I set them up. https://www.repairshopresources.com/valve-ttv575hp-00004

-

Dana 80 4.10's to 3.54 swap

PM sent.

-

Vibration after Southbend Dual Disc Clutch installed

Wow, some incredible dumbass install mistakes. Cardboard between the flywheel and crank? What??? Hand tight bolts? At least you quickly took it to someone else to get the issues resolved. Agree with other posts on this thread, I prefer to do my own work whenever I can. I did a full clutch job this past summer, installed a south bend stage II clutch and had my flywheel resurfaced. I replaced the rear main seal while I was in there. I took my time and double checked each step. Works perfectly. I know it's not possible for everyone to do their own work. Make sure you have a reputable mechanic from the get-go. Oh and yea regarding that ball bearing pilot bearing that comes with the south bend kit, It fits very tight on the input shaft. Good luck getting that trans to go in smoothly. Most guys end up cranking the last half inch in with the trans mount bolts. Mistake. I discarded that ball bearing pilot bearing and went with a solid oilite bronze pilot bushing. Fit perfectly and once I got that trans lined up it went right in smoothly without the need to use the trans mount bolts to crank it in.