Everything posted by TFaoro

-

My addiction

That WILL be fixed when I get off my lazy butt. If you know how a Ppump works, it shouldn't be too surprising. They reference fueling off boost, so you can cut the fuel down to near nothing when there's no boost. I'm sure @jlbayes has taken forever to dial his in..... For me it didn't take long with AFC Live. I know jlbayes hates the guys who build it, but for me it was the right choice. Setting the off idle fuel took about 20 (driving around and adjusting back and forth) Setting AFC Live takes about 10 min, and I can turn it down to tow anything I want without blowing the drivetrain apart. I highly doubt you'll see a difference with higher fuel pressure.

-

Skid Steer Surge

So it quit surging.... no idea why, but I'm not complaining! Engine is smooth as butter now. Fixed a BUNCH of hydraulic leaks this weekend. I think I've leaked about 5 gallons of oil since I got it, so this should really help. The drive motor on the left side has been replaced, and I'm assuming they never replaced the O rings (2 per fitting.) Onto the next thing!

-

trreed's upgrade thread

Use em as burnout tires! Don't forget to take a video

-

Smarty/TST stack still relevant?

I have lots of experience with the smarty and smarty / tst. Smarty alone with 7x.009 was a great towing setup Plenty of power and stayed pretty cool egt wise with the stock turbo. My issue with it was the smoke. If you didn't drive like you had a cracked egg shell under your foot it was a smoke machine. Getting moving quickly while in traffic doesn't happen unless you want to black out 2 lanes. Onto the stack - tons of power and smoke. I honestly left the TST off most of the time, but when I did flip it on it drove hard. My TST Comp liked to surge, so I wouldn't go that route. The PM3 was fine surge wise.

-

Shopping for an exhaust brake, what do you have?

Too much power / torque down low when towing breaks things. Head gasket, trans, etc. With that in mind, I think @Me78569 has a great setup.

-

Teardown and Rebuild

I'm going to try and get the miss fixed today, then bump the timing to the low / mid 20s. I think it's at 18 now. I think Weston can make just about whatever you want. He even made an 8x.010 or 8x.011 for Wade and he seems to like them.

-

Teardown and Rebuild

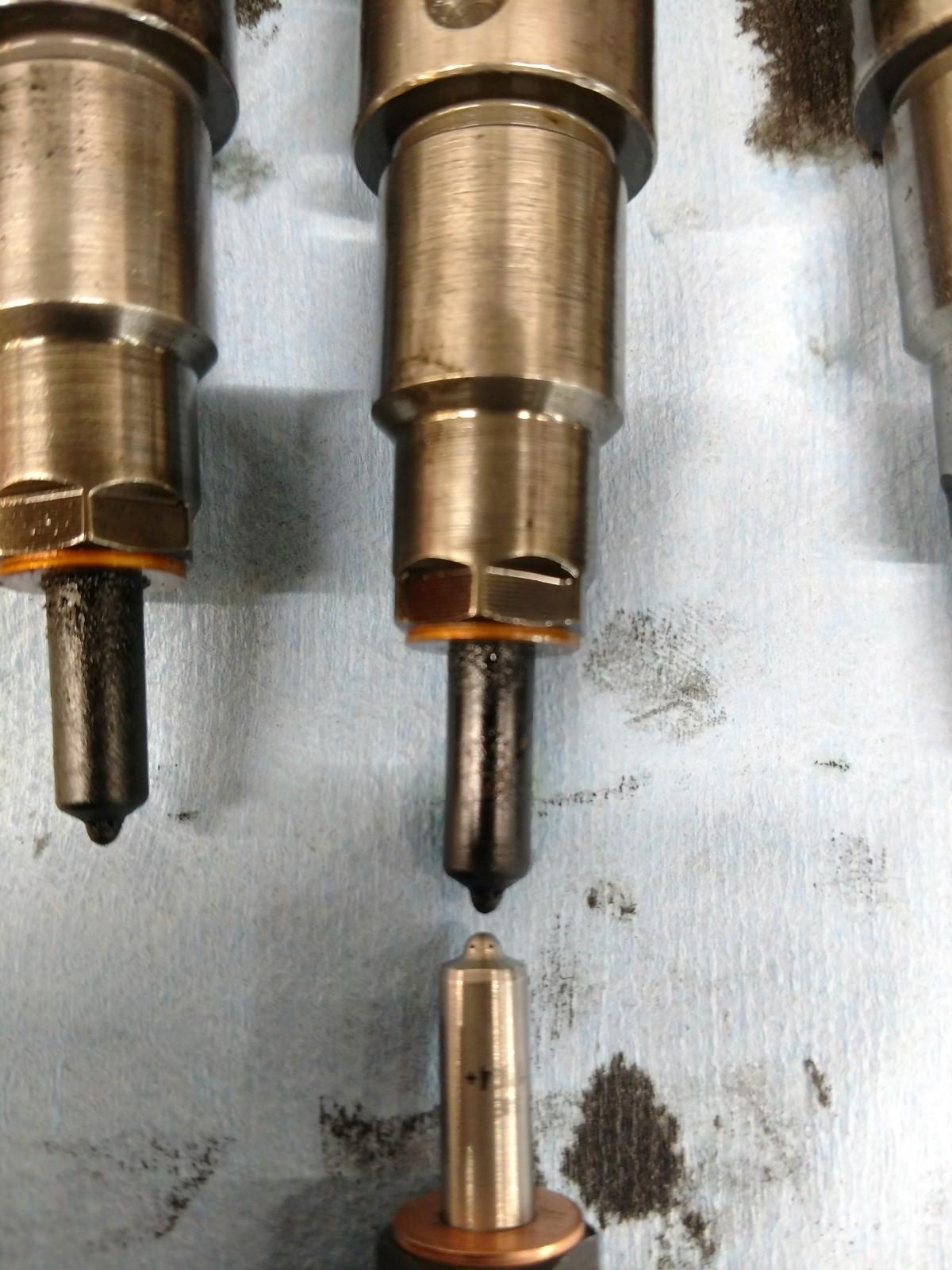

Correct, and they were pretty!! Little update on them - I got to drive the truck for 30 min or so. The injectors are not any dirtier than the old ones, and probably even cleaner off idle. They do haze about the same as the others, but they don't make the engine shake around at idle. I have not let the pump push all it can yet, but the EGTs and smoke are down while the boost is up. Almost 30psi out of the primary with a cracked boost gauge line. Fuel pressure stays up better with this filter setup and fuel lines. It's holding 4-5psi higher at WOT. I do have a couple issues - 1 the crossover tube O rings need replaced. (I expected this) 2 after the engine warms up it develops a slight miss. I'm thinking this is related to one of the injection lines not being seated when it's warmed up. I'll have to get it hot then crack all of the lines loose and tighten them back up. Hopefully that'll stop the shenanigans.

-

Teardown and Rebuild

Lots done tonight. Started by getting the filters bolted up to the frame. I used two layers of inner tube to absorb some of the shock from the frame. Got the lines and the bracket hooked up I ran the truck for a bit to make sure if any dust or contaminants weren't going to go through the new injectors. I then yanked all of the injectors. They looked absolutely horrible.... None of them look even remotely acceptable. Then I figured I might as well compression test it while I've got all of the injectors out. I was very happy to find all 6 were dead on the same compression at just under 400psi. Then the injectors went in. I can say it idles waaaaay smoother than it did. The engine doesn't shake at all like it did. Also, the copper washers are noticeably thinner. Not sure if that does anything more than keep the spray within the bowl. They have a nice haze at idle, but we'll see how they are driving. Cleanup in the morning, then I'll see if I can't go break something.

-

Valve Spring seller?

All manuals and 3500s have the Dana 80. 2500 autos have the Dana 70. You're correct about it being 98/99 HD. You could get the HD or LD in those years - LD being the Y style. IIRC the 98-99 HD steering has different TRE angles in the knuckles so they shouldn't be used in the 01/02 trucks. @jlbayes can confirm.

-

Valve Spring seller?

Stock. I can't think of the name I'll be buying one from (My stock cam is getting bad and the 188/220 in my sig was destroyed in 30k) @jlbayes knows the name of the company. What year is your truck? It could have the factory HD steering.

-

Teardown and Rebuild

That's pretty ridiculous they don't have it somewhere in writing. If I want to compare specs and they don't have the information available, I would just rule it out.

-

Teardown and Rebuild

Do you have a link to your info? I couldn't find anything on their site and I already closed the tab where I found it haha. I don't know how much fuel this Ppump will move, but it's a lot. My Fass 95 can't keep up - drops from 36psi to 18, and I've only got the pump set at 360cc's. It'll flow 450....

-

Teardown and Rebuild

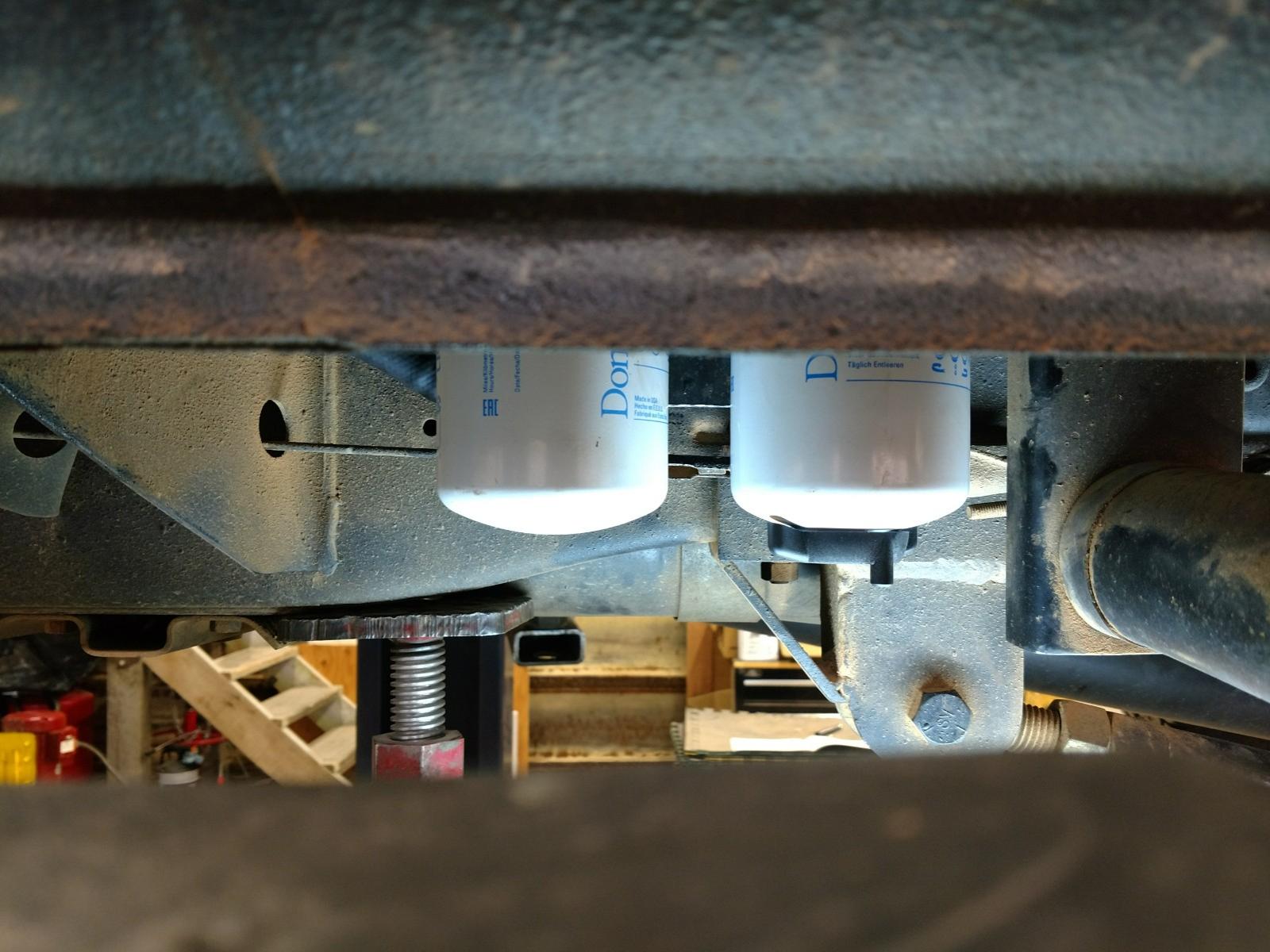

Maybe a touch I bet I could rip the filters completely off and the mount wouldn't move though!! Here's the only thing I could find on it: Fuel Filter Specs (BF1212): Flow Capability: 210gph @ 1psid / >300gph @ 3psid Filtration: 86% Efficient @ 4 micron / 99% Efficient @ 20 micron Water Removal: 93% @ 60gph / 87% @ 120gph (based on 2500ppm free water injection) (emulsified water removal will be approximately 3-5% less) Burst Pressure: 150psi Collapse Pressure: 100psid Here's the Donaldson Product Attributes Outer Diameter: 3.66 Inches (93 MM) Thread Size: 1-14 UN Length: 7.68 Inches (195 MM) Gasket OD: 2.80 Inches (71 MM) Gasket ID: 2.40 Inches (61 MM) Efficiency 99%: 15 MICRON Efficiency Test Std: SAE J1488, J1985 Emulsified H2O Efficiency: 85.00 PERCENT Type: Water Separator Style: Spin-On Brand: Twist&Drain™ Media Type: Cellulose Primary Application: CUMMINS 3308638 Notes: Not for Marine Applications Considering I'll be running in the 120+gph range, the Donaldson looks to have a better efficiency at a smaller micron, and it removes emulsified water better. From what I find, the Baldwin is great for pre-pump because of its high flow rate with high efficiency. Am I missing something?

-

Teardown and Rebuild

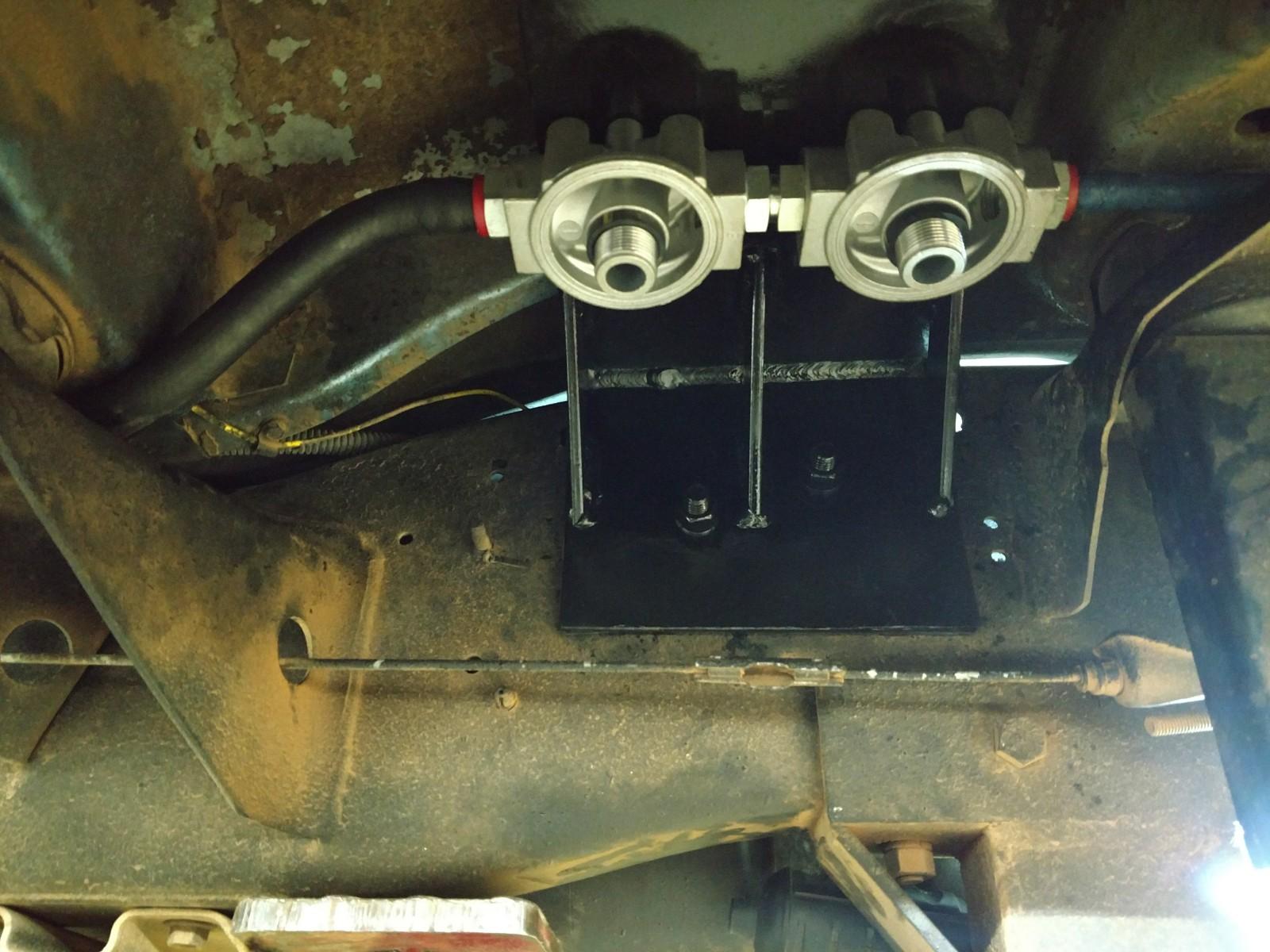

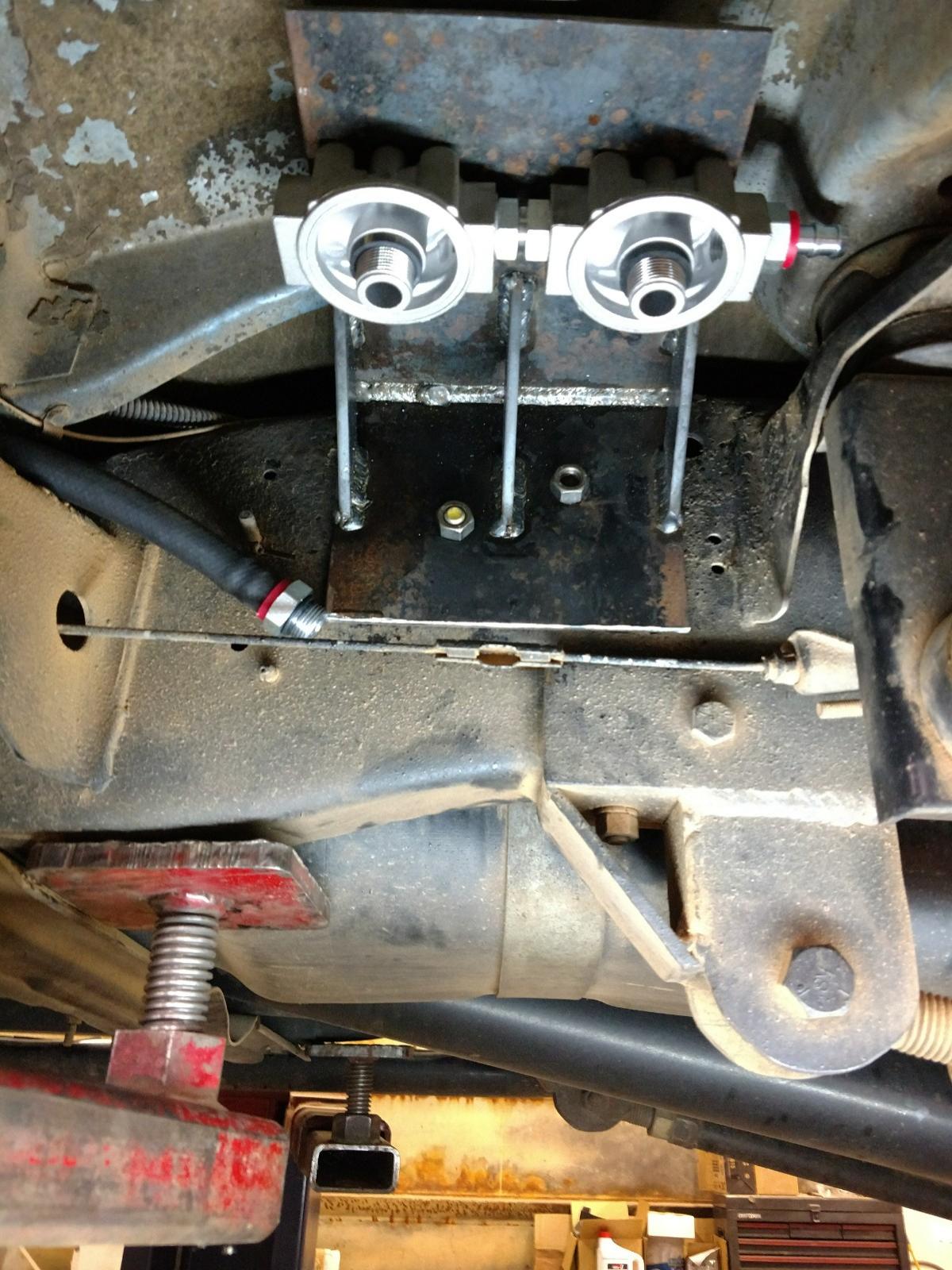

Started building the fuel system tonight. I ordered 2 filter heads, a Donaldson water separator, Donaldson 3um filter, 10 ORB to 10 ORB adapter, a 3/8 pushloc to 10 ORB fitting and two 1/2 pushloc to 10 ORB fittings. I started with a 7.5" wide piece of 3/16 AR plate, cut two sections, and butt welded them together. I then drilled the holes for the filter bases and where it'll mount to the frame (We'll get there) Then it wouldn't be mine if I didn't brace it with some 1.5" x 1/4" strap. Then I really braced it - FYI it'll hold all 220lbs of me against the frame with 1 tight bolt, so two filters should be fine! Here's where it mounts to the frame. Those were both existing holes, so no structural integrity taken out of the frame. (1/2in bolts BTW) Here you can see where the fuel line will run from the pump into the filters. BTW the closest mount to the camera is the rear cab mount. Here you can see where the Fass is mounted. I'll make a new bracket for the A1000 when I order it. Here's the bases and the mount mounted to the frame. Mounted with the filters Here's a shot of how low the filters hang. They should be very well protected by the frame and traction bar mount. Last picture. Now some of you may think this thing is rusting apart, but I swear all of the rusty color on the cab is diesel mixed with road base!

-

Advice before purchase

Unless he changed it, your dad's is an 11.5" AAM axle

-

Teardown and Rebuild

I'll try it without and if it works, great. If it doesn't work as well I'll pick one up. Text me your address and I'll get at least the actuator ordered asap so you can start playing with it.

-

Valve Spring seller?

Be very selective about who you buy it from. FYI Hamilton is NOT where I'd recommend.

-

junk in bottom of fresh oil containers.

@AH64ID should have some thoughts on this. IIRC it could just be part of the additive package and isn't a big deal. John will know more though.

-

Teardown and Rebuild

@Me78569 you're killing me

-

Skid Steer Surge

Sorry @Wild and Free I must have submitted the reply before typing my question!

-

Skid Steer Surge

So I got some work done on the skid steer this weekend. I replaced all of the fuel lines (many were cracked) I pulled the radiator and fan assembly back and removed the timing cover - The belt has been replaced, so that's a good sign. I also played with the governor adjustment a bit and it didn't make a difference with the loping. I set everything back to where it was though. @Wild and Free do you know much about hydraulic pumps / valves? I haven't dealt with them much. I did notice that the loping does continue while driving the machine, but if I use the boom / tilt cylinders the lope goes away while they're being used. Does that sound like a relief is sticking or adjusted improperly?

-

Valve Spring seller?

^^^Listen to that. Even then, if the stock one is fine - leave it alone.

-

Teardown and Rebuild

HOLY MOTHER OF PRICE TAG!!!!! https://www.aeromotiveinc.com/product-category/fuel-pumps/mechanical/ If it was a competition truck, maybe but for me that's a bit high. If the A1000 will be reliable, I'll go with it. - You have any info on its reliability at 50psi or so?

-

Teardown and Rebuild

I've been running like a chicken with my head cut off! It's sad when "Work" is where you get some spare time haha. I'll text ya back when I'm off work. I'll look that pump up too, sounds interesting.

-

Teardown and Rebuild

Spill the beans!!! Did you click the link and go to page 12 of the PDF? This is the cruise control stuff.