Everything posted by edcasey

-

01 problem with injector pump I think

I'm in Springfield but I have a very good friend who lives in Conway. I make frequent trips up to his family farm to pick up loads of rock. If you need a VP44, contact jkidd who is a vendor on this site and CF http://www.dieselautopower.com/. Jacob is a great guy to do business with. I paid $1000.00 for the pump and got an $80.00 rebate after 60 days so the total price was actually $920.00. His pumps are re-manufactured by Midwest Fuel Injection http://www.mwfi.com/. They replace all electronics and do all of the Bosch updates. The only way they wont accept a core is if it was in a fire or if it is disassembled.

-

01 problem with injector pump I think

I wouldn't be surprised if you also picked up some fuel mileage. My mileage increased 1.5 to 2 mpg with a new injection pump. I figure in just under three years the money I save from the increased fuel mileage will have paid for the new VP44.

-

opinions wanted please

I have the PSC version of the DSS. It's definitely worth every penny. Very easy to install and has good instructions. http://www.pscmotorsports.com/tech/install/sb100-installation-instructions.pdf

-

Help! The wifes truck died and thru a 1689 code

Were you able to restart the truck after it died or has it not been able to start? Mike has a write-up on common VP44 error codes here:http://mopar.mopar1973man.com/cummins/2ndgen24v/vp44-replace/vp44-error.htm

-

Straight Pipe Exhaust - 2001 4x4 2500

When I installed my MBRP 4 years ago, they sold a straight pipe with a muffler case around it. It looks exactly like a diesel muffler from the outside but the inside is just a straight pipe. It works great to get me through inspection. I did a search and can't find the MBRP version but did find this one; http://www.sourceautomotive.biz/shop/products/Sneaker_Muffler-458-13.html .

-

cummins diesel conversion on chevy truck

Have you been to this forum http://www.4btswaps.com/forum/forumdisplay.php?14-Cummins-6BT-5-9-Conversions . It's actually a site dedicated to 4bt swaps but they have a board for 5.9's. They should be able to give you a lot of help.

-

Overhead resets every shutdown

That's right Mike. The IOD (fuse 12) is the battery constant to the overhead. Fuse 11 provides power when the ignition is on to the overhead. If fuse 12 is blown, your radio wont hold station programming, power mirrors wont work, dome light and cargo light wont work.... Also Howie, check your right and left visor / vanity lights. They are powered by the same wire (from the IOD fuse) that provide 12 volt constant power to the overhead.

-

Unexpected results from new VP44

Thanks flman. I actually switch pumps daily. I've gotten in the habit of switching the toggle switch position before I put the ignition key in.

-

Unexpected results from new VP44

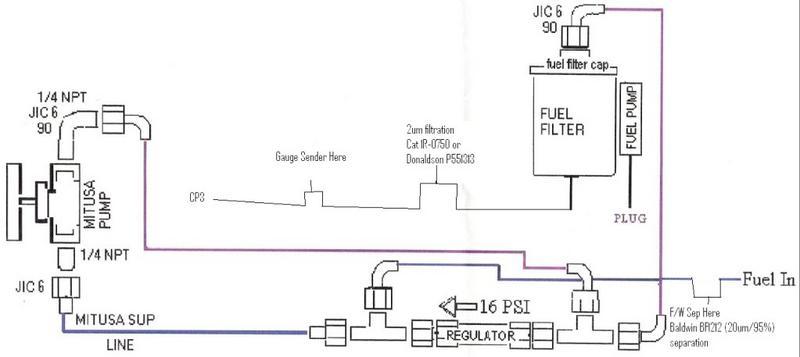

I'm really disappointed to here about the HP150. When I saw your writeup on CF it looked like a good alternative and your workmanship was impressive. I even PM'd you about posting it here. I was told to replace my stock pump with a Walbro 4 years ago by several RV delivery drivers who came into my RV dealership. I knew nothing about Walbro but for under $200.00 I bought two of them keeping one in the truck as a backup. Several of the delivery drivers had over 100,000 miles on theirs and one of mine is approaching 90,000. I think a prefilter is a huge help for longevity along with using the correct type of regulator so the pump isn't fighting against it's own pressure. 392's will exceed 100 psi without a regulator. As far as the relay causing a code, I haven't had a problem. The Fass and AirDog systems also use the original pump wire to trigger the relay and they don't throw a code either. It is a little confusing because some trucks will throw a P0230 when their pump is failing because the circuit is out of range. You wouldn't think a 160 mA draw would be enough to prevent the code but I have never got one. It would be interesting to find out what the parameters are for the ECM to throw a P0230. Maybe Mopar1973Man has some information about this. When I first installed a Walbro, I installed a return manifold into the fuel fill because that's what everyone told me to do. When I redid my fuel system I did give some thought to re-plumbing the return to a tee before the suction side of the pump. Opie's mechanical pump is plumbed that way; But I decided just to use the return manifold because it was already in place. I like your idea of a solenoid. That will make things easy to operate. I get quite a few questions asking why not run both pumps at once. A single 392 will pump 80 gph at 14.0 volts and 15 psi of pressure. That's way more fuel than my VP44 requires and my pressure never drops more than 2 psi. I use my truck to pick up wholesale campers all over the Northeast so having a second pump in place offers a lot of peace of mind and could potentially save a lot of money due to tow bills or lost time. A lifetime warranty pump is nice to have but having to wait to have one sent (even overnight) could cost hundreds of dollars. Buying a new $100.00 Walbro pump to replace a failed one is actually cheaper for me than waiting for a free replacement. I also like your idea of mounting everything on one plate to make service easy. I've read that emulsified water is harder to remove so the water separator should be on the suction side of the pump like on Fass and AirDog systems. The nice thing with your setup is you'll be able to run better filters than both of those systems.

-

Code P0753 troubleshooting

This is a writeup I did on another forum last year. I've pretty much abandoned other diesel forums so I thought I would post it here. A few weeks ago my truck suddenly decided to stop shifting and got stuck in 3rd gear (limp mode). It wouldn't up-shift or down-shift. I was able to manually down shift to second but it wont shift automatically and it couldn't be manually shifted to first. I checked for codes and got a P0753 which according to the manual is: Trans 3-4 Shift Sol/Trans Relay Circuits - An open or shorted condition detected in the overdrive solenoid control circuit or Trans Relay Circuit. I started threads on two forums asking for help troubleshooting the problem. I got several responses including replacing the overdrive solenoid, the governor pressure solenoid, pressure sensor, PCM.... I really hate throwing parts at a problem so I decided to do some research and start troubleshooting. I'm definitely not an expert at automatic transmissions but I have been repairing electrical problems for 20+ years. Using the 2001 service manual and information I found through Google searches I was able to fix the problem myself. What the P0753 is basically telling you is the electrical circuit responsible for shifting the transmission into overdrive isn't working. The circuit is actually very simple. Battery power goes through a 20 amp fuse to a relay than to the overdrive solenoid in the transmission and than to the PCM. The PCM controls the overdrive solenoid by turning on and off the ground allowing current to flow. You, of course, want to check the fuse first. Than swap the transmission relay and the horn relay (they are identical) and hit your horn. If it honks, than the relay is good. The next step is to check the circuit after the relay. You just pull out the relay and insert one probe of your multimeter into the slot shown in the picture. This is the slot that sends power to the transmission. Next, you want to remove the center (white) connect on the PCM. The PCM is located on the firewall behind your air cleaner. Just push down on the tabs that are located on top of and under the connector and pull the connector out. Turn the connector over to see the pins (holes). They are marked with small number. Touch the probe to pin 21 but be careful not to jam the probe in and damage the pin. Set your multimeter to Ohms and get a reading. It should read about 31 ohms. It shouldn't read open like mine does. This tells me my overdrive solenoid circuit is open some where. It's more than likely the solenoid itself but could be the wires or the connector on the transmission. My next step is to remove the transmission pan and filter. The overdrive solenoid is located under the filter. The filter is held on with two T-25 screws. The govenor solenoid body needs to be removed first. Its held on with four 11mm bolts and two T-25 bolts. The overdrive solenoid is actually part the of the transmission control solenoid assembly which also contains the torque converter clutch solenoid. The transmission control solenoid is held on with three T-25 bolts. Also, disconnect the wire that goes to the connector. There are also two zip-ties that need to be cut off. I wanted to see exactly what was wrong with the overdrive solenoid so I removed the black plastic cover that's over the solenoid coil and the problem was obvious. The coil wire was broken. I got a new transmission control solenoid from a local parts store for $111.00. I'd hate to see what a Dodge dealer would want for it. The new one also comes with the wires. I tested the new part just to be sure. I'd hate to get it back together and find I have a bad part. The overdrive solenoid and the torque converter clutch solenoid are identical and both tested good at 31.4 ohms. I put everything back together. I used the old wiring harness because replacing it requires removing the valve body. I couldn't see doing the extra work to replace a harness that is good. The final steps included a new filter and 8 quarts of fluid. I took it out for a test drive and it works perfectly. Total cost was $153.87. Just a few additional notes on this problem: When the PCM detects a short or open circuit in the overdrive solenoid circuit it shows a P0753 code and places the transmission into "limp home mode". What that means is the PCM shuts off the transmission relay so no power goes to the transmission. This is actually what causes the transmission to stick in one gear. This caused me some headaches while troubleshooting this problem. If you look at the wiring diagram below, you'll see the transmission relay secondary circuit receives power from the PCM (through the same wire that provides power to the alternator field winding) and than the relay power returns to the PCM for a ground. When the PCM detects a P0753 it shuts off the ground for the secondary circuit. This stops the transmission relay from closing and the transmission goes into "limp home mode'. The other thing that caused me some confusion is the 2001 service manual shows pin 86 on the transmission relay as receiving power from the PCM and pin 85 being the ground back to the PCM. This is backwards from my 2000. I don't know if it's a mistake in the manual or if they switched it for 2001. Good luck with your repair. I hope this helps if you ever have a P0753. __________________

-

New Lift Pump Q's

I really, really hate to give a CF link, but this guy did a great job with his Fass vs. AirDog writeup. http://www.cumminsforum.com/forum/3rd-gen-performance-parts-discussion/163170-fass-vs-airdog-you-decide.html

-

01 problem with injector pump I think

If you need a new VP44, one of the vendors on this site, Jkidd, has the best prices available. I saved over $100.00 compared to the next lowest price. His pumps are from Midwest Fuel Injection. They have an excellent reputation and they replace the electronics on every pump along with all Bosch updates. He's a great guy to do business with.

-

Unexpected results from new VP44

Hey Anton, The bypass valve is the same as this one http://www.speedwaymotors.com/Hilborn-Primary-By-Pass-Valve-Brass,317.html except I got mine from Glacier Diesel. It's the same bypass valve they use in their Fuel Boss setup. They also sell the return manifold http://www.glacierdieselpower.com/product.aspx?pf_id=38112RM that is installed in the fuel fill hose to return the unused fuel to the fuel tank. The bypass is adjustable by removing or adding small shims. It only takes a couple of minutes to change them. Once you have the pressure where you want it, you wont have to touch the bypass again. The Walbro 392's are gerotor pumps. If my older pump ever fails (almost 90,000 miles now), I'll open it and take pictures. The nice thing is these pumps wont allow any flow if their not being powered. So the pump that is off acts as a check valve when you run one pump at a time. I choose to wire my pumps to a relay so the pumps gets nearly full battery voltage. The 392's draw less amperage than the stock Carter so you could hook a single Walbro to the original ECM wire but there will be more voltage drop than using a relay.

-

01 problem with injector pump I think

What is the fuel pressure at wide open throttle?

-

No tranny lock up in od!

Wild, he wrote 1765 in two posts and 1756 in the last one so I'm not sure which is correct.

-

No tranny lock up in od!

Ahh...Having a jumper in place changes things. Removing the relay and installing a jumper wire can cause a 1765 but it should have done it right away. But seeing you ran it for quite a while without a code it doesn't seem likely that it's the problem. You could temporarily install a relay in the trans relay spot just to confirm. You could use the horn relay if you don't have the original relay handy. Your ECM definitely isn't fried. It's the PCM that controls the relay and produces the code. The ECM isn't involved. The PCM also has an internal voltage regulator that controls voltage to the generator field. We'll have to wait to see if your alternator is functioning correctly.

-

No tranny lock up in od!

The 0500 indicates a problem with the vehicle speed sensor. Sometimes this will appear if you spin the rear tires on ice, mud..... The P0622, P0743, P0753 and P1765 are all related problems. The P1765 indicates the circuit from the PCM that triggers the transmission relay to close is not producing the correct voltage. This circuit might be open or shorted. The same circuit also is used to excite the alternator field. Because the voltage is wrong to the alternator field you get a P0622. The P0753 indicates the transmission relay isn't closing which is caused by the PCM trigger circuit not functioning correctly. The P0743 tells you the torque converter circuit is out of tolerance. This also makes sense because that circuit gets power from the transmission relay which isn't closing. So basically, the PCM signal that closes the transmission relay and powers the alternator field isn't functioning. This causes the transmission relay not to close. Without the transmission relay closing, the governor solenoid, lock-up solenoid and overdrive solenoid all do not get power. If this is a hard failure your truck will go into "limp mode" and will be stuck in 3rd gear. If the truck shifts normally, than it's an intermittent problem. Have you tried to clear the codes to see if they will come back? Did someone remove the transmission relay with the ignition on? Is your alternator gauge showing 14.0 volts or so with the engine running or is it showing battery voltage (12.6 volts or so)?

-

its beat to death but i gotta ask , lift pump issues uhhg

The STK 1001 is FASS's version of a Draw Staw. It's basically a 1/2 tube that you install in you fuel tank to avoid the restriction of the stock fuel pick. You must install one if you have an in-tank fuel pump. Is FASS recommending this with both pumps or just the 150? AirDog only requires it with their bigger pump. Installing the STK 1001 will require dropping the fuel tank or removing the truck bed. Not a huge deal but it will add to installation time. Both pumps will pump much more volume than your injection pump requires. The excess volume is returned to the fuel tank and wont harm anything or cause a code. The fuel heater in the stock fuel canister will only keep the stock filter from being clogged by gelled fuel. It wont do anything to prevent the two Fass filters from gelling. But I would keep the stock fuel canister if it was me. The FASS 150 system does have a 3 micron filter available so filtration isn't an issue but the FASS 95 only has a 10 micron filter available. Also, water separation isn't very good with the Fass at just 50% free water separation (emulsified separation is unknown) it's not very effective. If you keep the stock filter canister, you can use a Baldwin PF 7977 which will give you 5 micron filtration and separate 99% of free water and 95% of emulsified water.

-

Thankful for a fuel pressure gauge!

I know exactly what you mean about the fuel pressure gauge. Last year I stopped at a gas station in Augusta Maine. Within a few miles I noticed my fuel pressure was down a little. By the time I got to the New Hampshire boarder, my fuel pressure gauge was reading 5 psi going up hills. I thought for sure my fuel pump was dying because both my fuel filter and prefilter had less than 500 miles on them. But sure enough, after a few minutes of troubleshooting, I figured out my in-line prefilter was clogged. I always carry an extra so I replaced it. This was a 140 micron screen that got clogged in a very short time from one tank of bad fuel. The funny part is there was absolutely no change in engine performance. Without the gauge, I wouldn't have been aware of a problem and would have kept driving with very low fuel pressure.

-

Most linked thread on the Internet. Need a good laugh...

Some of you may have seen this before but because I've read that the thread in the link below is the most linked thread to date on the internet. It's on a Ford Explorer website but really has nothing to do with them. It was open for over 9 years and has over 460,000 hits. The first post has been edited but originally the person who started the thread asks: "How do I get Herculiner off of my hootus ". He posted this as a serious request for help removing Herculiner from his manhood and his buddies are absolutely merciless. They make up song and videos (post 264) and radio stations even play parodies about his problem. You can even buy "I got Herculiner on my hootus" t-shirts and coffee mugs. I found it years ago and someone reminded me of it today and it's still funny to reread. http://www.explorerforum.com/forums/showthread.php?t=18595

-

Another lift pump question

Are you getting the 8 volts when you bump the starter or when you turn your key to the "on" postion?

-

Best online spot for OEM lift pump and Oil question

I think you hit the nail on the head with the in-tank pump. When it fails it's way more labor to replace than a frame mounted pump especially if your not close to home when it fails and you have to pay to have someone else do it (my trucks rarely give me trouble unless I'm more than 500 miles from home:banghead:). For under $400.00 you can get a Raptor 100 or 150 with a lifetime warranty that is very easy to install or replace in the event of a failure. The only draw back with the Raptor (or AirDog) is in the event of failure you would have to wait for a replacement to be sent to you. Than again, if your local Dodge dealer is like mine, they stock only common replacement parts and would have to order an in-tank pump if you needed a replacement one.

-

its beat to death but i gotta ask , lift pump issues uhhg

Ranger, have you been to Mike's (Mopar1973Man's) website? http://mopar.mopar1973man.com/ He's got a lot of great info that can answer most or all of your other questions. It's the best source of information about 24 valve CTD's on the internet.

-

its beat to death but i gotta ask , lift pump issues uhhg

Hey Ranger,Welcome. If you don't mind ordering a pump, Jkidd (one of this sites vendors) has some great deals and is an excellent guy to do business with. With the mild mods you have, a Raptor 100 would be plenty of pump and would save you money (list price is $389.00 American). This is a very reliable pump with a lifetime warranty. The installation is easy and you don't need to add a Draw straw to the fuel tank. If you run a Baldwin PF7977 filter in your stock filter housing, you'll get excellent filtration and water separation for less money than the Fass.

-

Still hearing stock lift pump after Raptor Install

The Raptor will pump for 2 seconds when you turn the forward just like the stock pump. It seems like that is what you are hearing..? You absolutely shouldn't hear the stock lift pump because the wire from the ECM that powered the stock pump is now used to trigger your Raptor relay so the stock pump has no voltage going to it. Whether you remove the stock pump is totally up to you. It wont hurt anything to leave it there. I choose to remove mine. If you do remove it, just remove the pump itself and not the mounting plate. The plate actually covers a hole in the block that was used by older models for a mechanical pump.