Everything posted by Tim Waldo

-

no crank, no start (jump the solenoid wire, starts and runs fine)

So it is going to take more diagnostics on circuit B, there was no voltage through A at all.... I put in a push button to get by for now (I actually wanted a push button as an additional layer of security) I am pretty sure the ignition switch just bit the bullet. So by chance do you know where the bypass is for the clutch bypass is? Always a good to know. THANK YOU for the schematic. Tim

-

no crank, no start (jump the solenoid wire, starts and runs fine)

So, 2000 RAM, 5 speed. I have bypassed the signal wire and jumped to 12v and engine starts, I have checked all fuses and relays (to best of my knowledge), I also jumpered the clutch safety switch which did nothing.... Wait to start light still works as expected, what would keep the 12v signal from making it to the starter? I know I can just put a push button in to bypass but I want to make sure this isn't a bigger picture issue. This literally popped up outa no where, stopped at a store, and when I got back in it wouldn't crank, I had to roll start it, luckily was on a slight slope. Thanks in advance. Tim

-

New IAT, temp goes above 293, watch it drop on the code reader

Yes painful to the extreme, the shop did not help matters ANY... Vette your shops if you are going to trust your truck with them.

-

Transfer Case Shifter Linkage Rod Bushings

That is AWESOME... will remember for future reference.

-

Transfer Case Shifter Linkage Rod Bushings

SO... I broke down and called a local Dodge dealer... they looked it up for me. They had to look from the transfer case side to even get the grommet part number... but with it I was able to find THIS. https://torqueking.com/product/10589/qu10589-transfer-case-shift-linkage-grommet-or-bushing-for-dodge/?dfw_tracker=64486-3171&cmp_id=17998788702&adg_id=&kwd=&device=c&gclid=Cj0KCQjwmvSoBhDOARIsAK6aV7jyF49S_6OWbRI5zVCtBeIdLBKnFGmzPpYmHND-6rXCilird-QUf90aAhtrEALw_wcB

-

Serpentine Drive Belt - What is the best

-

New IAT, temp goes above 293, watch it drop on the code reader

SO... finally got my truck back at the first of August and though I no longer trust the shop, this is what I THINK happened. VP44 died, was replaced... started throwing codes for the IAT almost immediately.... New VP44 was replaced as a failed rebuild, upgraded the VP44 and ordered injectors and tubes and a new IAT sensor installed 2nd VP44 with new injectors and tubes, still through IAT codes and melted a 2nd IAT sensor Sent to a shop. They found cylinder 5 in some state of disrepair (this is where I loose trust in the shop) I don't know if the cylinder had a hole in it or what. (shop ordered the wrong long block first and installed it wondering why truck kept throwing a crank position code) Shop corrected the long block issue and installed a 2nd new long block, with new injectors and then there was drama with break in oil (they put full synthetic in it for break in and post breakin) never got me the warranty paperwork and eventually I contacted the remanufacture shop, got specific directions on breakin oil and started that process over and ended my relationship with the shop. Currently breakin with DINO oil is complete, and I have my truck back again (after $14k repair bill).

-

Transfer Case Shifter Linkage Rod Bushings

The shop that was doing the work on my truck got a DORMAN replacement and it didn't work at all. The kicker is I'll find something specifically listed as a replacement for a 2000 dodge but then when you look in the details it is for 2002 to 2005 or something like that.

-

Transfer Case Shifter Linkage Rod Bushings

I just need the bushings for a 2000, 3500. I'm not trusting what I am seeing online. Where would you guys purchase?

-

AC drain issues

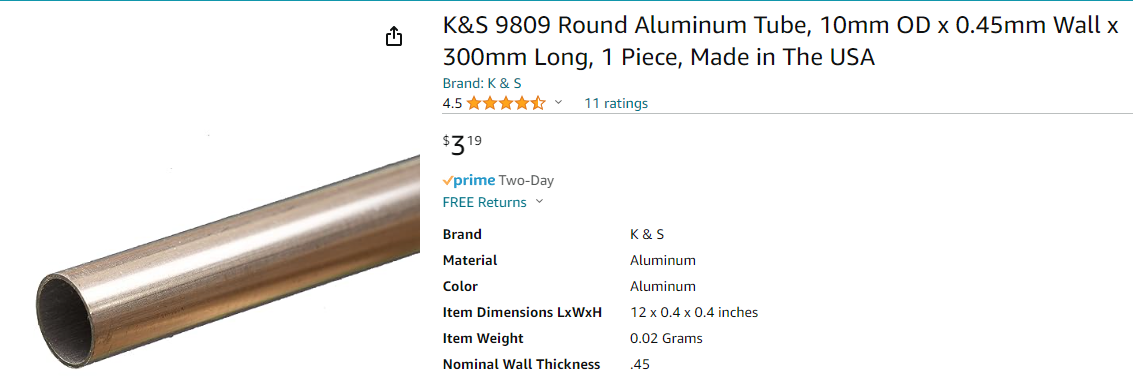

So final repair. 10mm OD aluminum pipe , two wraps of electrical tape, some rubber fuel line and some plumbers putty.

-

AC drain issues

So I ordered this tubing, it was not actually 10mm OD, it was 9 by my meter (cheap plastic from harbor freight).... SO cut it in half so I have 2 6" pieces and tried one for size... it was way loose... I marked it for depth about an inch and half pulled it and cut it down a bit more. I then got the electrical tape and played with how many times to wrap it to get a snug fit (about twice) placed it in the hole and extended with a bit of tubing that I had that would fit over and zip tied the tubing to the frame to secure the tube a bit more. Going to make a 100 ish mile round trip and see how it works. If anyone were going to order similar tubing from amazon I would try 11 mm OD. OR go with the 10 and know you'll need to add something to take up the gap. Total metal tube length was 4" when I was done. Photos later.

-

AC drain issues

THANK YOU... that is exactly what I needed. Yeah, prior to this I had a foot long piece of water hose clamped to mine. I am VERY frustrated with the shop because I am SURE it happened on their watch and they are totally denying anything happened. I'll let you know how this goes...

-

AC drain issues

The problem is, where you have a nipple sticking out past the firewall.. if you look at my photo, mine is recessed into the firewall... looks like it has been cut or broken off. If you could verify I would REALLY appreciate it... I miked the ID at 3mm, someone confirming would be AWEESOME. I actually ordered some telescoping tubing from amazon in hopes one of the sections would fit inside of the pipe and I'll cut it off and epoxy it.

-

AC drain issues

I can't get to it that easily, maybe if I had a lift.... had to contort pretty heavily just to get the photo.

-

AC drain issues

This is the problem, the pipe that stuck out is now flush, if not recessed a bit.... honestly looks cut to me but the shop owner was like my guys would NEVER do that... and I'd swear it was sticking out almost 2 inches when I sent it to them for the engine work.

-

AC drain issues

Nope, no cracks that I can see, though can see where the water has been leaking from the firewall back into the cab. Any idea what the inside diameter of the tube is? I'll just get some aluminum tubing that is just the right size and epoxy it in.

-

AC drain issues

so you think it was cut rather than pushed back? insert the tubing INTO the metal tube? there isn't enough metal sticking out to put tubing around it and clamp. Or do I have bigger problems and it has cracked my HVAC box?? I've only had the dash off once to put a new heater core in and don't remember how it looked, actually I don't think I moved the HVAC box at all during that process.

-

AC drain issues

As you can see, the tube is recessed, I believe it was pushed back while it was in the shop getting the engine replaced... https://photos.app.goo.gl/xGfBWrPxEVdmixyd9 https://photos.app.goo.gl/KU7x3hpmXF5rNfCP9 https://photos.app.goo.gl/GXqZCPGzihAunuQW6

-

New IAT, temp goes above 293, watch it drop on the code reader

so maybe it wasn't my mechanic dropping something into the intake? 5 and 6 get un-naturally hot? Taking a lot of factors into consideration, I bit the bullet this morning and started the shop on the rebuild process... still $$ well spent. water pump and belt tensioner are easy replacements.

-

New IAT, temp goes above 293, watch it drop on the code reader

I looked at your rebuild kit... I don't speak rebuildereese , so I don't know what half that stuff is... can it all be done with engine IN or engine out? I mean I get pistons and rings... but wrist pin bushings??? I'm lost.

-

New IAT, temp goes above 293, watch it drop on the code reader

@Mopar1973Man you are just making me feel like the lottery winner for the worst cummins engine... I am torn over pay them to do it, do it myself or just throw in the towel and buy a 3rd gen..... literally new batteries and tires in December, new trackbar and steering stabilizer days before the first VP44 change and then injectors... and now a GOOD VP44.... so about 5k in already.

-

New IAT, temp goes above 293, watch it drop on the code reader

I asked the shop for specifics on which valve was burnt... based on your response... I'll let you know what they say. as for their quote, did the prices seem correct ?? Should I go for the new long block?

-

New IAT, temp goes above 293, watch it drop on the code reader

Ok.. got the NEW VP44 installed and working.... SO it was time to take it to a shop because it was eating IAT sensors... This is the email I requested from the shop. Suggestions on next steps? I mean if I go with the whole block at 13k I basically have a new truck... and all the issues of original truck (cracked/missing dash, dents, dings and messed up paint)... They could not give me any information on if the mobile mechanic did anything to mess the engine up, they did say he failed on best practices of doing a compression test when he replaced the fuel injectors and that one step could have possibly saved the engine. 2000 Dodge Ram 3500 Performed a compression test and found that vehicle had noticeable misfire. 1-410 2-415 3-410 4-450 5-125 6-400 Noticeable problem with cylinder 5. Took apart and found that Cylinder 5 had burnt valve, walls was scored and has caused damage to the piston. Rebuild short block and fix the cylinder head would be $11700.00 + tax 1 year warranty New long block which will have a new cylinder head would be $13200.00 + tax with a 5 year warranty.

-

New IAT, temp goes above 293, watch it drop on the code reader

DT, I've got a couple of posts all tied to my VP dying in January... the IAT did NOT show up until after he did the initial work. Had to pull the VP44 and send it back to the company that sold it and then he put in the 2nd VP44.. I am presuming that he dropped something in the intake, so that wouldn't have been originally posted... just the end result of following the path... I didn't pull the original IAT sensor until after the 2nd VP44 was installed... thought gee , how odd that it is melted... put the new one in... continued to throw codes... pulled the new one out and it was melted as well... then I started digging and found a post where someone had a similar issue..... Truck gets delivered to a diesel shop tomorrow and MAYBE by Wednesday I get an answer.

-

New IAT, temp goes above 293, watch it drop on the code reader

Will do...