Everything posted by The_Hammer

-

springs or leveling kit

@Wild and Free That's how I do it as well.

-

springs or leveling kit

Something to remember is that it doesn't take much lift at all to make an adjustable track bar a needed upgrade. Also, the ride will be rougher unless you install some extended control arms. This is due to the steeper angles of the control arms caused by the axle arcing back towards the cab. I'm running 2" coil spacers and needed an adjustable track bar to center my axle up. I'm also going to build some new control arms to push the axle a 1/2" foward of the stock location. Bottom line is that you can dump some money quick getting things set up right, even with just a couple inches of lift. This is how it sits with spacers and add-a-leafs.

-

Buying 2005

I was on my phone and it sure as **** looked like a DTC lol. Looking at it from a PC I can tell it says ROUGH now. I'll be over in the corner if anyone needs me.

-

Buying 2005

It was checked for a bad injector, hence the cylinder balancing test. #3 is a little low. P0617 is "starter relay circuit high", I couldn't find a P00617. I can't make out the last four characters after that code.

-

Cowboys Head Porting Endeavor

I've got just under 300k on mine, hopefully it will be in spec when I finally replace the head gasket and stud it.

-

Did the power steering pump mod this evening and

I don't do any serious off-roading with my truck, especially since there really aren't any places to go around here. I drive a mix of payment and gravel, the roughest stuff is down at Matagorda with 20+ miles of shoreline to drive on. It gets pretty bad at times, wash outs and dunes. One thing I'm really liking about about the 315/75/R16 Goodyear Duratracs I'm running is that they balance out VERY well, just as good as a stock size tire. I had some 37x12.50R16.5 Goodyear OZs on while I was saving up for some 16" rims and the Duratracs. Those things balanced like complete **** and shook the whole damn truck, I couldn't wait to get them off. They were cheap though ($250 for the set) and got me to work and back though. I can only imagine how fast they would destroy all the steering components if left on the truck.

-

Cowboys Head Porting Endeavor

How many miles on the engine?

-

Cowboys Head Porting Endeavor

Looks good man. Are you going to have the head resurfaced while it's off?

-

Teardown and Rebuild

So what was the cause of the knocking? Don't feel like digging through 30 pages to find out lol.

-

Front end

Yep . People want big trucks but don't want to spend big bucks.

-

Quadzilla is Back??!!!

I'm still trying to figure out where to plug one in at.

-

Front end

There's a shop in a town about an hour away from me who builds all kinds of abominations. Want a progressive rate coil spring lift? Weld two sets of springs together with a couple of u-bolts thrown in for good measure. Custom made track bar? No problem! Some scrap pipe with nuts welded in the ends, some all thread, and more scrap pipe welded on the ends of the all thread and your good to go. It makes my head hurt just thinking about it.

-

Front end

Measurements? Angles? Pft. That stuff is for people who lack mad skillz brah. Everyone knows you just slap on a 16 " lift, cut the front spring buckets, tilt the axle forward, weld em' back on, then bolt on a killer set of quad chrome steering stabilizers and slam a couple monsters for a job well done. Newton's third law:" For every action, there is an equal and opposite reaction". It is one of the most basic concepts of physics, yet is apparently the most difficult to comprehend judging by some of the things I've seen. Proper suspension geometry is what I'm after on my truck. The 2" coil spacers I have lifted the front enough to pull my axle about an inch off center towards the driver side, and almost the same distance back towards the cab. The adjustable track bar allowed me to center the axle back up, which, combined with eliminating the play in my wore out stock track bar, corrected my steering issues. I'm planning on replacing the spacers with 3" lift springs and building a set of extended control arms that will push the axle a 1/2" forward of the stock location. Ultimately I would like to do a long arm or possibly a long radius arm set up for a better ride. Sometimes I wish these trucks had leaf spring front ends. Lifting my old 82' K5 Blazer 6" was stupid simple. A raised steering arm and dropped pitman arm brought the draglink angles back to stock. A simple sway-bar disconnect extended things back to stock as well. Too bad the stock ride sucked though lol.

-

Transmission Oil Cooler Line Replacement

The side of the transmission doesn't use regular 1/4" NPT (national pipe tapered) threads, it's actually NPS (national pipe straight) threads. This is the adapter you need for the transmission http://m.summitracing.com/parts/fra-481670-bl Then just pick your choice of barbed AN fitting. The cooler has barbed fittings, the hoses are held on with hose clamps. The heat exchanger fittings are No. 8 male JIC.

-

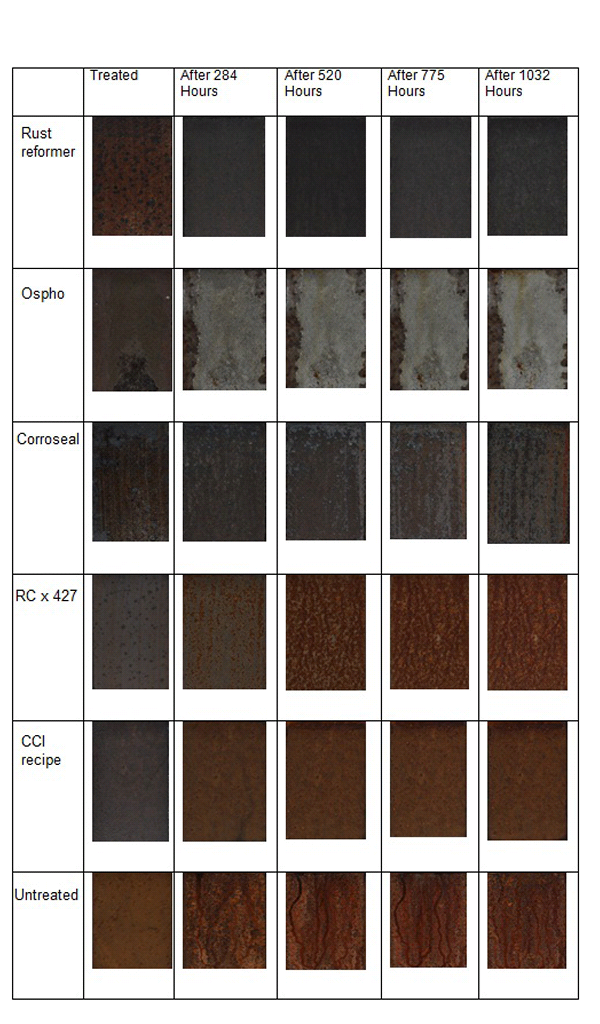

Time to kill some rust!

Found this interesting study on some rust converters by the NCPTT which can be found here. Below is an excerpt. "The five chemicals chosen for this study are listed below. The chemicals were chosen to represent each of the major types of rust converters. The chemicals in each category were selected based on their popularity in the commercial market place. The goal of this study is to provide the end user be it home owner or museum conservator with the knowledge needed to make an informed decision when selecting a rust converter. Rust-oleum® Rust Reformer® is a tannic acid based rust converting product. It also has an acrylic vinylidene chloride copolymer additive. Tannic acid acts as a chelating agent while the copolymer creates a protective coating. The product has a pH of 2.13, falling in the mid-range pH of this study’s converters. Rust Reformer® has a relatively thick consistency, and is blue-ish white in appearance. OSPHO®, manufactured by the Skybryte Company, is a phosphoric acid based rust converting product balanced with dichromate and wetting agents. OSPHO® is by far the most acidic rust converter of those tested. The product’s pH is 0.08, and is a thin, translucent green liquid. Corroseal® is a rust converting product based in gallic acid. This converter is composed of gallic acid, ethylene glycol and acetate. It is relatively acidic, both generally and in comparison to other tested converters, with a pH of 1.50. Corroseal® is creamy white and has a thick consistency Intern Anna Muto applying rust converter to test samples. RCx427 is a product of Enviro-Safe Services, Inc. that uses oxalic acid as the rust converting compound. Like Corroseal®, it also incorporates ethylene glycol in the chemical composition. Oxalic acid as an active ingredient—a compound that exhibits different physical properties after conversion. Instead of causing the iron oxide layer to darken, it instead turns a light gray. Of the tested rust converters, this product is the least acidic with a pH of 3.11. RCx427 has a thick consistency and is a blue-gray color. The 10% Tannic Acid solution stands out from the other rust converters in that the solution is not commercially available but must be prepared. However, a survey of metal conservators done by conservation graduate student Rose Daly indicated that the “CCI Recipe” for tannic acid solution was used more often than commercially available rust converting products. As such, it was deemed important to include in the study. The preparation method outlined in the CCI Note “Tannic Acid Treatment” was followed (CCI Note, 1989). As directed, 2.75 mL of phosphoric acid was added to lower pH to 2.39, and fell into the mid-range of acidity in this study’s converters. The solution is thin and appears a translucent, orange-red color. At the end of the accelerated weathering only the samples treated with Rust-oleum® Rust Reformer® showed no or only slight signs of any failure and no active corrosion. This research was completed in the summer of 2012, afterwards the results were presented at ICOM CC Metal 2013 in Edinburgh, Scotland. The results of the study were also published in the conference proceedings. Click here for pdf of paper."

-

Front end

I needed an adjustable track bar, otherwise I would have gone the Lukes link route. An adjustable 3rd gen track bar conversion isn't any cheaper.

-

Time to kill some rust!

I wish I could get my hands on the stuff my old work place used on salt water disposal tanks. They would refurbish some ratty old steel tanks that were covered in sheets of rust that were over a foot long. They would knock all the loose rust off then spray it with a reddish/brown epoxy primer, wait a day, then paint it. There were tanks out in the field 5+ years later that were still rust free.

-

Time to kill some rust!

Have you tried sand blasting? It was another idea I was kicking around.

-

Time to kill some rust!

Well the current plan is to remove as much of the rust as I can with a wire wheel, weld up the holes, apply a couple coats of Rustoleum rust converter, and hit it with some Rustoleum primer. Once I have the funds available I'll spray on some bedliner.

-

Super B Update

That's how it is here. There are HS kids driving Ford Raptors and new Ford and Dodge 3/4 ton trucks rolling on 40's. All because mommy and daddy lucked out and had a gas well drilled on their property. It wouldn't bother me except that they act like complete dickheads.

-

Did the power steering pump mod this evening and

Great write up Cowboy! @Mopar1973Man I see people upgrading their gears because the stock ones are "wearing out too fast". That's normally caused by poor steering linkage geometry from a lift and large tires. I had a buddy with an 02' Ram 2500, 18" of lift, and 44" boggers. He kept trashing gear boxes until he added a ram assist and a custom built tie rod with heim joints, after that he never had an issue.

-

Front end

On a stock height truck I'd go this route. If it's lifted I'd go with a DOR adjustable track bar here. One thing about DOR is to make sure the part is in stock before ordering. People have had issues receiving their "not in stock" orders in a timely manner. It is a VERY well made part that (to me) is a much better option than a 3rd gen conversion. For ball joints check here. I'm about to order a pair myself.

-

Super B Update

I hear ya man, times are tough lately.

-

Did the power steering pump mod this evening and

I already replaced the seal, the old one had a sloppy fit and was completely wore out. I'm eventually going to do a rebuild, would you mind sharing your way of dealing with the BB's?

-

Can a man just get a break?

My gray water line is plugged up now, I blame you OP Jk (My grey water line really is plugged though)

.thumb.jpg.fca947f9d2810360be8189f93912c04c.jpg)