Everything posted by kzimmer

-

Intermittent starting problem 1998 dodge

eBay, double din, with a die grinder.

-

Intermittent starting problem 1998 dodge

Could the starter have a dead spot?

-

5 speed

That doesn't sound right. Any vibration in the driveline? Does it get worse with speed? Maybe a bent driveshaft? Loose/worn trans mount?

-

The crf450ish random question thread.

I'm not sure what situation got the 400 amp load, or if those gauges were hooked up properly. Or if they are accurate. However, I did blow my fusible link once. And it was because after I'd had taken the grid heater off a couple times, I wore out the insulating material where the lugs bolt on to the grid studs. The funny thing is it didn't do it right away. Maybe a week or two after I touched it. I must have had barely a little bit of insulation between the grid heater frame (ground) and the power cables, and it finally broke over and shorted, at least partially. Might be worth checking. Also might be worth checking inside the grid heater to see if part of the element is touching ground anywhere. Also those current indicators, is that the value it showed after the fusible link blew? If so, that just shows current got to a maximum value before the link blew. I put my fluke clamp on ammeter on my grids and measured max draw a while back... But I didn't write it down. Wish I did.

-

The crf450ish random question thread.

If this is the case, then you want an alternator field disconnect. Install an auxiliary relay that energizes when the grid heater activates, and wire the alternator field wire through a normally closed set of contacts on the auxiliary relay. The grid heaters will never go through the alternator again. I can't buy this theory. Its just a heater element. The only way it can increase in current draw is for the resistance to be lowered. The element, if anything, would increase in resistance if it were damaged. This would lower current draw (and associated heat). It would take some pretty heavy foreign contamination to decrease the resistance. What I could buy, is that a lot of trucks with not so healthy batteries and/or battery connections will have a slightly higher resistance connection to the batteries than the alternator. Electricity will always follow the path of least resistance. Under the extreme electrical load of the grid heaters, a poor battery and/or connection will demonstrate a decrease in available voltage. The alternator, which is by design at a higher potential, coupled with the possibilities of a storage system (batteries and associated connections) that may not be at 100% working condition, will take more and more of the electrical load as external conditions worsen. A disconnect of the alternator field should prevent the grids from raping the alternator of maximum power either way. I'm very curious to find out if that slows down alternator diode failures.

-

Testing Injector Pop Pressure in the real world

See! I'm not crazy. Haha.

-

Testing Injector Pop Pressure in the real world

Either that or more fuel. I always thought retarding timing aids in cold starting (to a limit of course). When I still had the 7x.014's in, I noticed cold starts improved when I upped them from factory to 340 bar. 7x.013's at 365 bar were brutal. Down to 330 bar and it's not bad. Except I still have a problem where the longer I leave the truck, the harder it starts. Issue is compounded with colder weather. Gotta be air getting in somewhere but I don't have a clue. No visual fuel leaks. Assuming I can resolve my starting issues, I think these 7x.013's will be happiest at 330-340 bar. I'm likely going to take them out one more time, set to 340 bar, and put on a better set of copper o-rings. These were generic from a local parts store and might not be helping the situation. I measured them and they seemed ok... But meh. Good to rule it out.

-

Testing Injector Pop Pressure in the real world

Excellent! Well not good that your truck is starting hard, but good that we are seeing common data.

-

Testing Injector Pop Pressure in the real world

Ugh... Tempting, haha. Every time I work on something on this truck without fixing an oil leak I feel guilty. Can you force your truck to stall? At 365 bar I could force a stall fairly easily. The odd time by accident. At 330 I can't even force one, no matter what I do. Maybe once, in an extreme situation that's almost impossible to recreate. Especially since the pop may have settled to 320ish bar anyway.

-

Testing Injector Pop Pressure in the real world

Mine settled from 365 Bar to 350-355 Bar. Seems like a good bet that you'll drop 10 Bar after setting. Makes me wish I reset mine to 340 instead of 330.

-

Testing Injector Pop Pressure in the real world

Very interesting. There seems to be a plateau that occurs somewhere between 330 and 350 bar. A lot of this info jives with mine. I never recorded idle state rpm in gear like you did, but I saw the same thing with the naked eye.

-

Cold... Very cold

Negative. Always RPM on the tach when cranking, no CEL, and after it fires it runs great and starts great after immediately shutting off and restarting. I guess this is pretty old and I haven't updated. The issue got a little better after re-popping injectors to 330 bar from 365. I had a couple small fuel leaks. The issue was (is) air in fuel. I replaced every single fuel line and fitting from tank sump to VP inlet. Introduced a much better pre-filter strategy before my Walbro pump to cut back on possible air. It's much better now, but the longer it sits, the more I have to crank to start it, especially when cold (-32 celsius last night). Still a bit of air getting in, very slowly. Not enough to keep the truck down, but enough to piss me off.

-

Custom Quadzilla Tuning R & D Thread

I really don't like that wormhole.

-

Custom Quadzilla Tuning R & D Thread

I wouldn't hook it up. I'd leave it sealed up. I think with proper tuning, wastegates on single turbos are a logical falsehood. I mean if you couldn't control fuel properly based on boost then it's necessary, but with the control we have it's a no brainer.

-

Quadzilla install question

To be honest, I think the control pod should be discontinued. This tuner needs the app.

-

Custom Quadzilla Tuning R & D Thread

Haha, for the amount of fuel I could probably find one here!

-

Custom Quadzilla Tuning R & D Thread

That's why I got second gear lockup. Sooooo much better. I still want a manual though.

-

Custom Quadzilla Tuning R & D Thread

Yep.

-

Custom Quadzilla Tuning R & D Thread

Neat! I'm working the next 10 days (ish) in a row, but I would definitely like to test it after that.

-

Custom Quadzilla Tuning R & D Thread

Possibly. Sounds fun and dangerous.

-

Testing Injector Pop Pressure in the real world

I've personally noticed a very large fluctuation of EGT's during idling this winter. Nothing recorded. But with different combinations of ambient temp (and subsequent IAT), and ECT, I've seen it float around quite a bit. Not saying this is the case 100% for you, but it makes sense that it could be a little inconsistent.

-

Testing Injector Pop Pressure in the real world

I had mentioned when I first went to 365 bar that it sounded like my idle got a little noisier, a slightly more pronounced rattle. If you've ever heard an injector on a pop tester this makes sense. Pop any given injector at 280 bar, and then 365 bar, and they definitely sound different.

-

Custom Quadzilla Tuning R & D Thread

If I'm understanding this correctly, the quad is not in any sort of control in your situation. I saw similar results with mine at 365 bar, although I have an automatic. The addition of factory anti-stall will likely add complication to this. I believe we have basically found the upper end of pop pressure being tuneable with the Quad. To fix these starting and off-idle issues will likely require ECM program changes that we can't do.

-

Custom Quadzilla Tuning R & D Thread

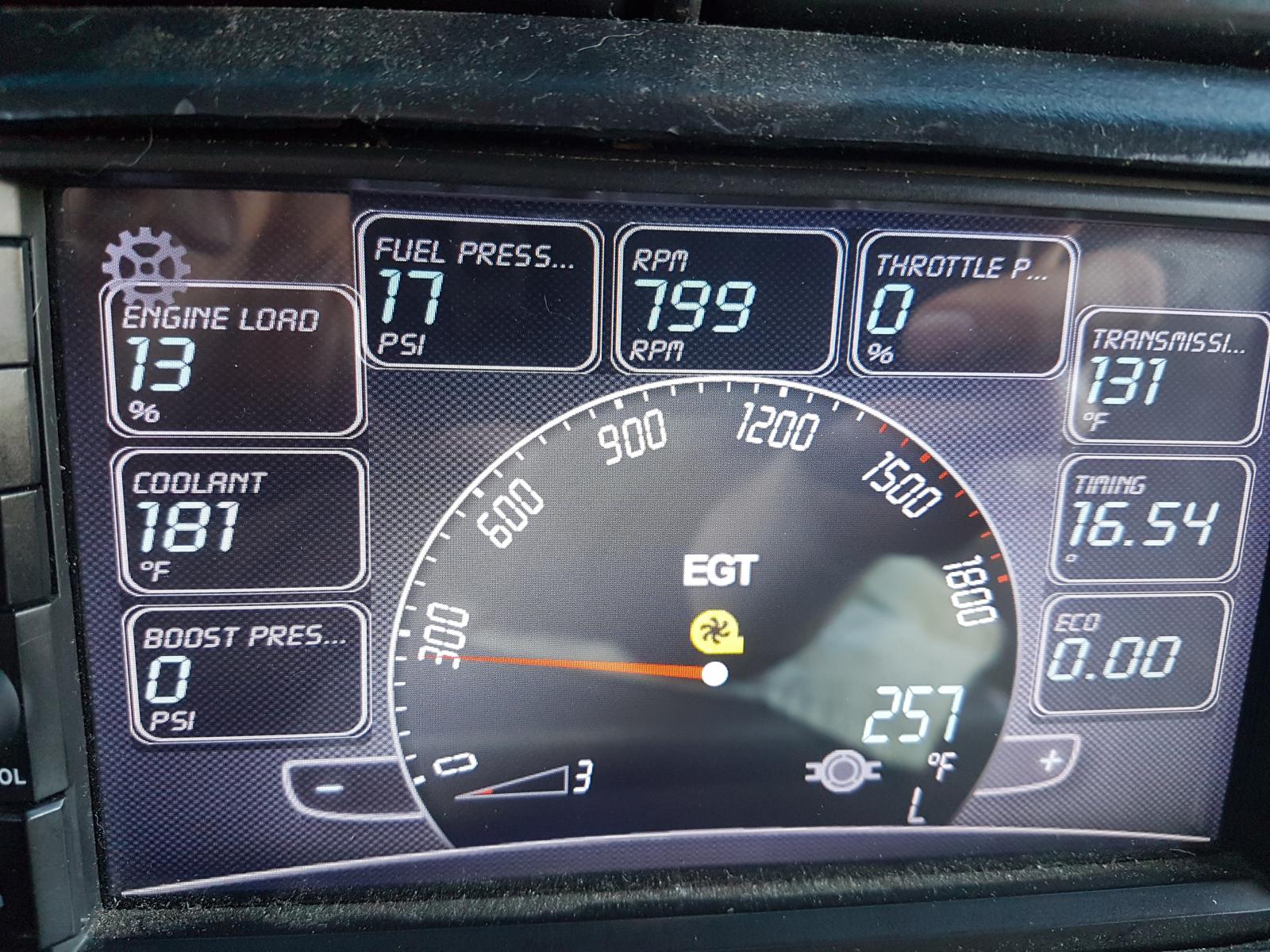

Here's mine after almost 1 hour of city errands today. 16.54°. It's cold outside! Looks like I need to crank up the fuel pressure regulator a hair as well.

-

Switched to Quadzilla iQuad!

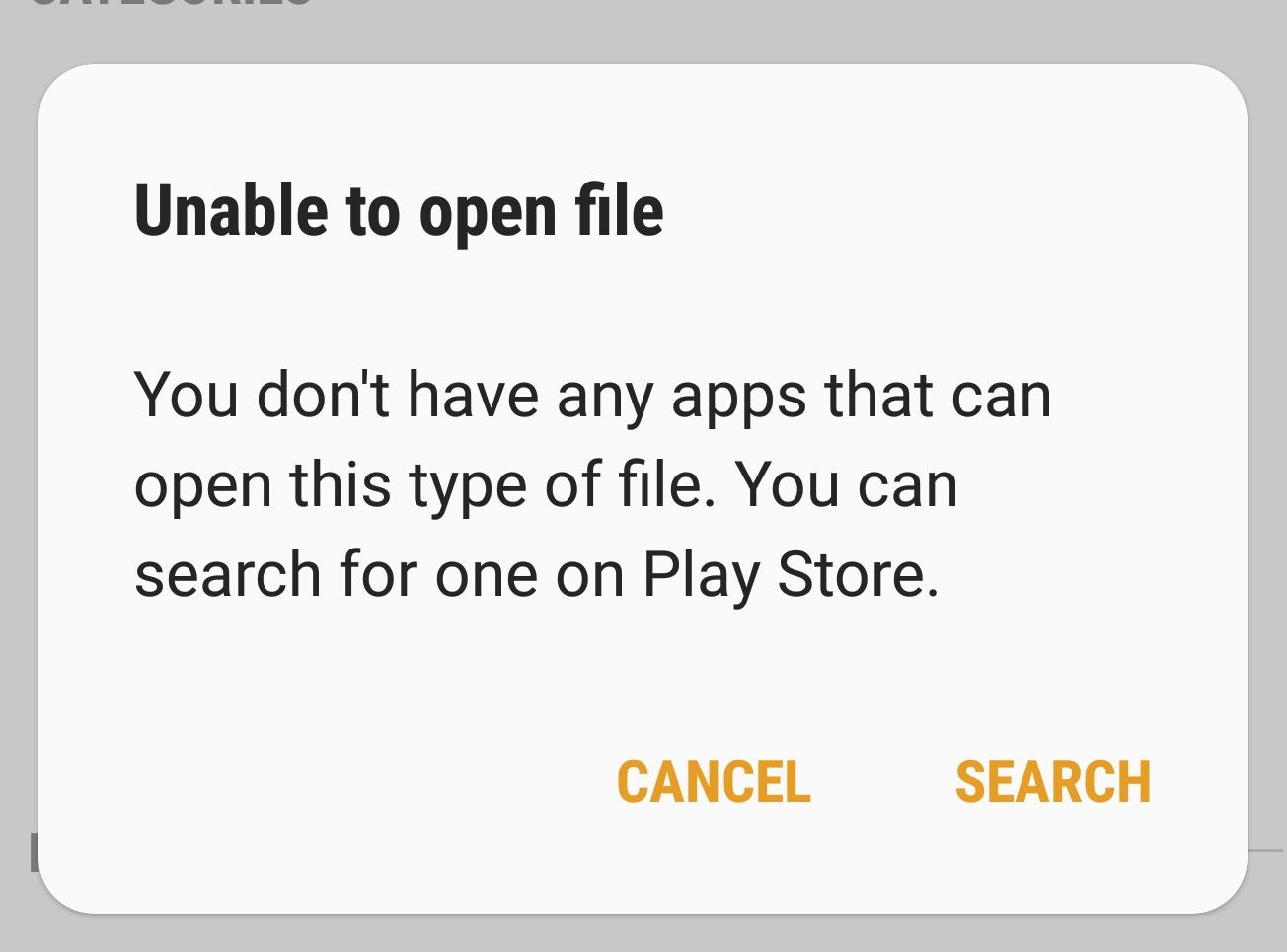

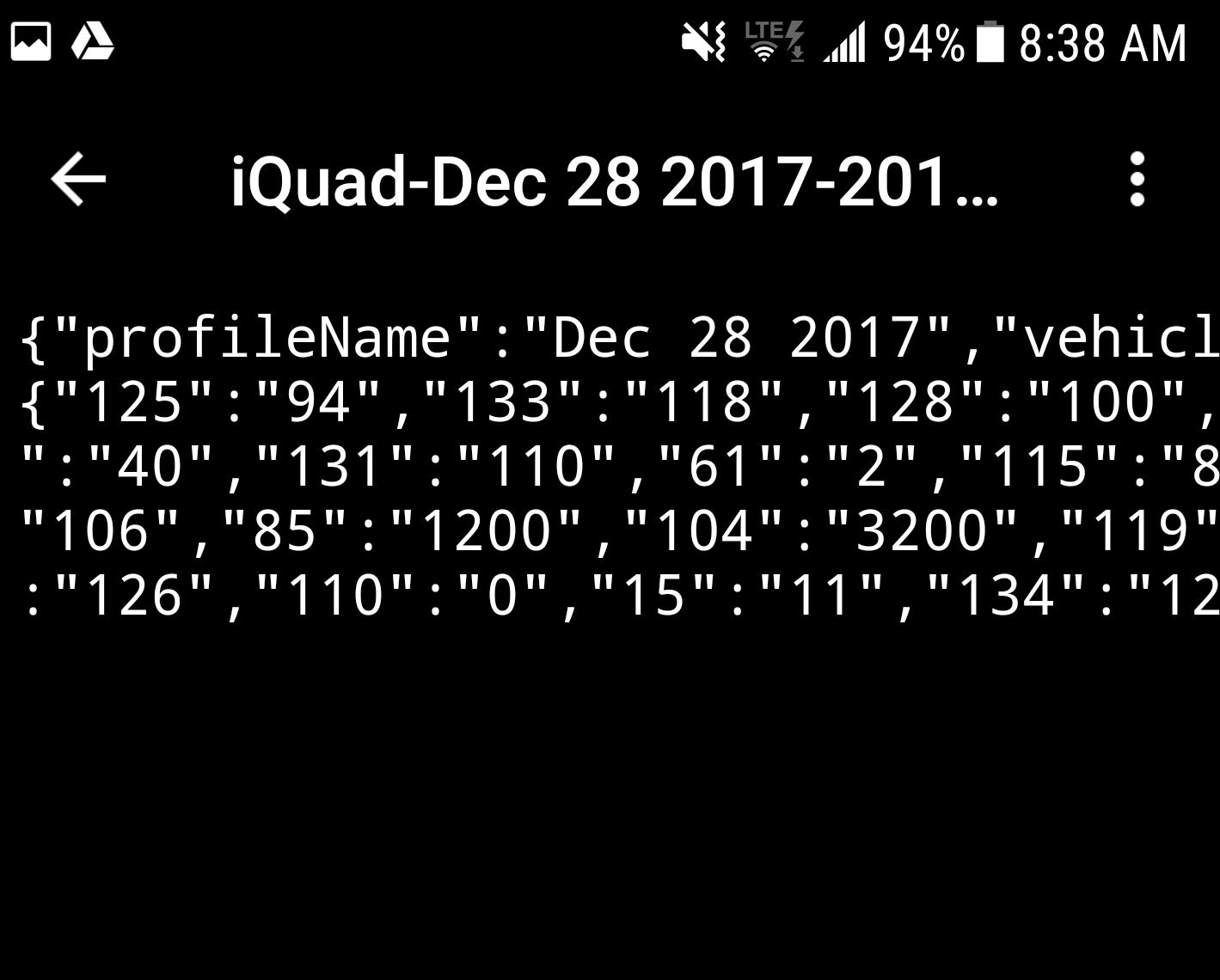

@Dieselfuture @Brignac@Me78569 I use a Samsung Galaxy S7 whenever I need to datalog. If I just click on a tune in my download folder, it will tell me this: Here's what I do. I made a Quadzilla/Tunes folder on my Google drive. With the Google drive app on the Samsung device, send the tune file to Google drive. I usually open the app first, and actually go right to the custom tunes screen for good measure. Then minimize with home button open and go to the Google drive app. Click on the tune. It should open something like this: Click on the 3 dots in the top right corner. Then click open with. And then pick then iquad app.