Everything posted by bjytech

-

Nv4500 rebuild time

This morning I was on my way to work not even a mile from home I let of the throttle to slow down for a curve and the I heard a pop then I got the lovley sound of a great missing teeth, limped her back to the house in second and just finished taking it out tonight. I found that what happened is the main shaft 5th gear washer broke and a piece got between the main shaft 5th and country shaft 5th and took a chunk of gears out of them. Anyone have any ideas what would cause that washer to break up into many pieces? On the bright side I have it down to where I can pull the transfercase and trans out by myself in less than a hour and a half

-

difference between dpf and def

There is still a DPF with the use of DEF and the DEF is consumed. Like John said the DPF traps the particulates(carbon) that come out of the engine in the exhaust stream, then once it collect so much it will run a regen injecting extra fuel into the exhaust to get the temps up in the 1100°F range to clean the DPF out. The DEF is part of the SCR system, it is injected into the exhaust stream in a decomposition chamber that is right before the SCR catalyst, when the DEF is injected into the decomposition chamber is reacts and turns to ammonia, then in the SCR catalyst the ammonia and NOx react and form water vapor and nitrogen.

-

Odd Vibration

I've been looking at the cooper S/T maxx for my next set of tires, I have Nitto terra grapplers on now and with only 10k miles on them they are at 50% tread, so I'll probably be buying tires sometime next summer.

-

Gaming...

I'm the same way, been playing America's army: proving grounds and battlefield 4 lately. My steam is bjytech

-

Tach & Speedo inop.

Is the alternator charging? if not you have a problem with the engine speed sensor, if the PCM doesn't get a signal from the ESS it doesn't know the truck is running. Check the gap between the ESS and the engine damper quick easy way to set the gap is to use a business card between the ESS and the damper.

-

New BHAF options!

I wouldn't mind having a nice air box to go with a filter like this, I have a amsoil air filter right now just out in the open, if I remember right the filter I have is about half the size of a regular BHAF but flows a little more and filters the same and cost right around $70 regular price iirc. I think a air box looks better under the hood than just having a filter laying there.

-

injector power rating

Yes it it.

-

01 dodge speedo doa

I don't think you have a bearing problem, I think the tone ring just moved out of place, after looking at some others the tone ring should be right up against the ring gear, but from your pictures it looks like it has a pretty good gap there. If you had a bearing problem it would be seen on the ring an pinion gears not the tone ring. The tone ring is just pressed onto the carrier from what I see.

-

01 dodge speedo doa

Well I just tried to take my sensor out to get you a picture but it's stuck in there pretty good so I just left it alone before I broke it.

-

01 dodge speedo doa

its been a while since I've had my diff cover off but I'm pretty sure the tone ring teeth are supposed to be squared, it looks like your's got wore down pretty far against something at some point, it should also be fairly centered in the hole for the sensor to get a good reading.

-

Almost done! Need a little help

Have you tried following the wire back the other way to see what the other end goes to?

-

Help....Know just enough to be dangerous and having problems

P1693 is a companion code so there's more in there that you will see once you read the codes with a computer.

-

HE351ve install / retrofit 2nd Gen Cummins

On the Cummins ISX's that have the VGT turbos, I know it uses the following for controlling the turbo. Intake manifold pressure Intake manifold temp Engine load Exhaust back pressure (in the manifold) Turbo shaft speed Turbo compressor intake temp There could be a couple others such as the TPS and fueling rate that play in as well but I'm not sure about those, and of course there are times the ECM will control the turbo/whole engine very differently than normal like when it runs a re-gen or is in engine warm-up operating mode on a cold day.

-

2015 truck pull

It was at the Holmes County fair

-

2015 truck pull

I placed 5th, 302.55 ft, the track was hard and really dry plus the sled seemed light, top 3 trucks had a pull off because they all had to stop in the dirt pile at the end.

-

2015 truck pull

Pulled my truck tonight at the county fair, there were a total of 5 trucks in the workstock/2.5 class I pulled in. I was the only one that drove my truck in. At least 3 if not all 4 of the other truck were 2.5 trucks.

-

oil in coolant, no coolant in oil. bad cap, next test?

For something Like that I prefer genuine cummins parts, pulling the oil cooler out is pretty straight forward, just a bunch of bolts to take out. Back when I blew a head gasket on my truck I pulled the oil cooler out and plugged one hole and put a blow gun with a rubber tip in the other and while blowing pressure in it I submersed it in a tub of water, I didn't get any bubbles though.

-

p7100 12v Fuel system upgrade

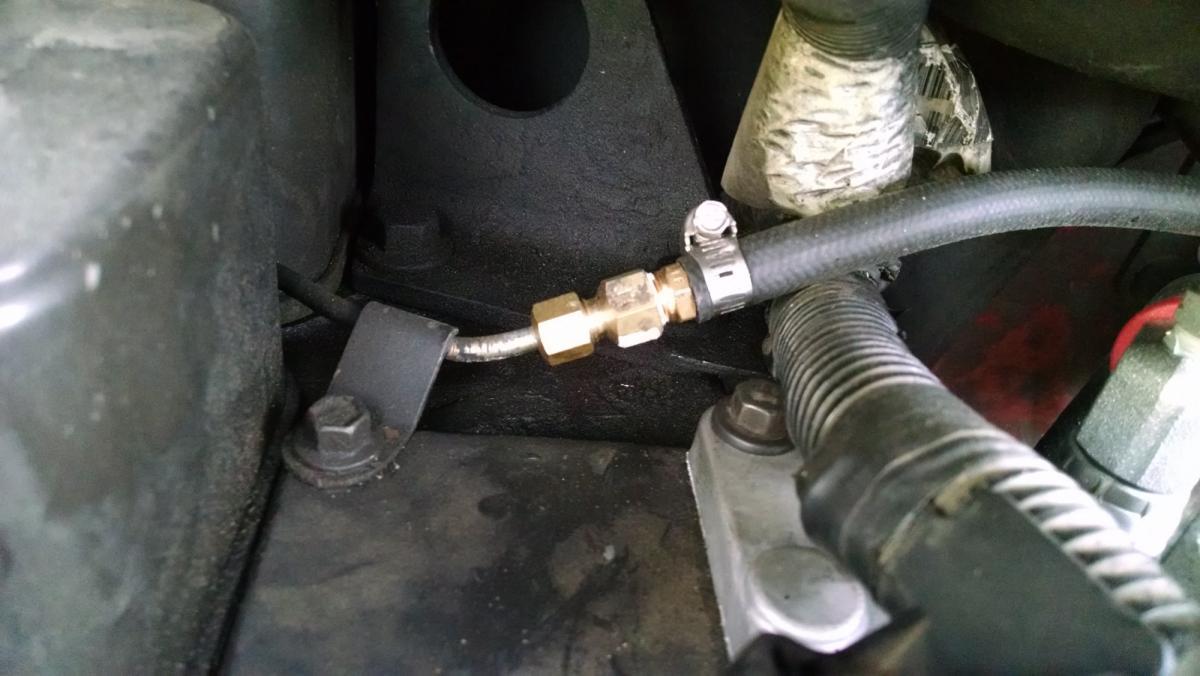

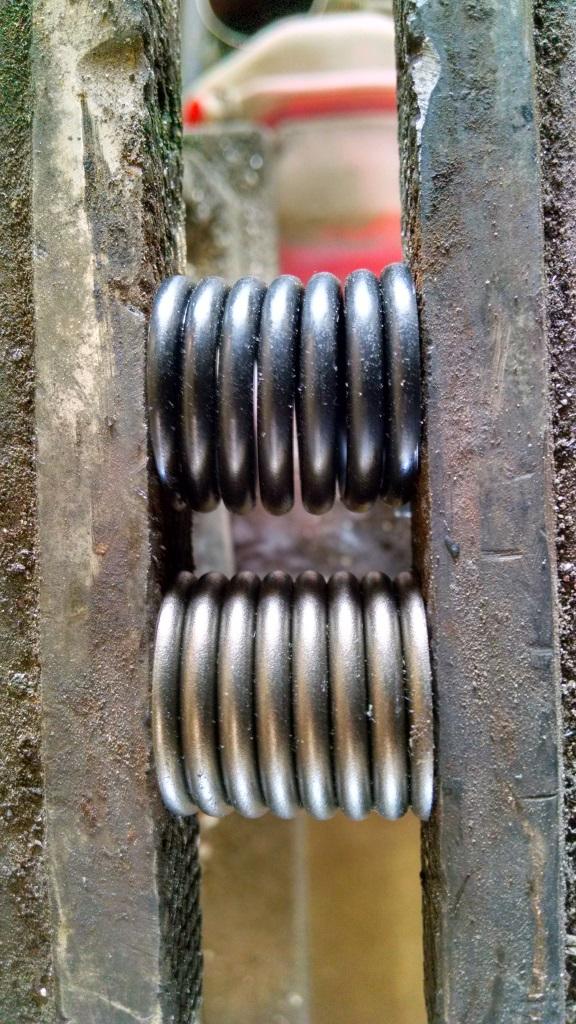

After reading the fuel system threads that Cowboy and Dauntless89 (thank you both for the info) have posted over on cummins forum I decided to do some work to my fuel system since I have been having some issues with fuel supply since going to bigger injectors. What I did was run new 1/2" supply line from the fuel tank all the way up to the injection pump. At the tank I have a G&R diesel sump with integrated return (return unused atm) with a 1/2" NPT to 8jic push lock onto the fuel line. From the tank it goes straight to the lift pump where I have a 1/2" NPT 90° with another 1/2" NPT to 8jic push lock onto the fuel line on the fuel inlet, and on the fuel outlet I have a m14 to 8jic 90° push lock. Then it goes up to the filter housing which I changed out from the 97 style canister filter housing to the earlier spin on filter housing. I drilled and tapped the ports on the top of the filter housing out to 3/8" NPT and drilled the center of the filter thread adapter out to 3/8" as well. (didn't get pictures of that though) On the filter housing I have a 3/8" NPT to 8jic in each port and have tight 90° 8jic to 1/2" push lock with 1/8" NPT ports tapped in them. On the clean side of the filter I have my fuel pressure guage sender in the 1/8" port and on the "dirty" side of the filter I have a 1/8" NPT to 4jic onto a 4jic 1/4" push lock that goes to the injector return line where I cut the steal line and used a 3/16" compression fitting going into a 1/4" hose barb. then to the filter housing. At the injection pump I put a m14 to 8jic adapter with a 8jic to 1/2" push lock into the hose from the filter housing. Besides the fuel line upgrades I also upgraded the spring in my stock lift pump to a 973-1 comp cams valve spring. Here it is side by side with the old stock spring. (this is the original lift pump the truck has had on since the factory 18 years ago) After these upgrades with NO other changes I my fuel pressure at idle went from ranging in the 5-20psi range to holding steady at 25-27. and at 3000 RPM (no load) it holds 45-50psi under WOT conditions I have yet to see it drop any lower than 37psi. I can definitely tell that I was starving for fuel before the upgrades, I have better response, better spool up, less smoke, and more power (according to the butt dyno) than before. I had planned on doing some things to the return system as well but after seeing the results I got from these upgrades I feel for my current setup I don't have to worry about my return system for now. All the hose and steel fittings came from Vulcan performance, the black fittings came with the fuel sump, and the brass is from the local hardware store.

-

NEED TURBO OIL INLET FITTING O RING

The fitting is m12 iirc so it's probably metric

-

NEED TURBO OIL INLET FITTING O RING

It looked like a regular sized O-ring to me when I had that fitting off changing turbos. You should be able to find one that will work just fine at any hardware store. quickserve doesn't give any dimensions on it but the cummins part number for that O-ring is 3037236

-

From 24 valve to 12 valve

For the KDP I take the fan off at the mount on the engine (four 10mm bolts) save the one behind the pulley for last as the fan will have to move out as the bolt comes out. Then take the bolts out of the fan shroud and pull the fan and shroud up out(put cardboard or something between the fan and radiator first). once that is out of the way you get a nice amount of room to remove the damper and front cover.

-

From 24 valve to 12 valve

I think you are thinking of the "attitude adjuster" from Attitude performance products.

-

From 24 valve to 12 valve

I've only seen one 2 wheel drive truck try to pull that I can remember, all it did was a one wheel peel at the start line, if it had a limited slip differential it might have got going but i don't know.

-

From 24 valve to 12 valve

I just tend to forget about it really, I like running for how smooth it seems to make things. I don't know the autos to well but since it does it in both forward and reverse I would think it could be from the torque converter. I'm sure other with more knowledge in that area will chime in. The pulls I've done so far my truck was right around 350hp so its not that powerful, shifting really isn't possible when pulling with a manual, I just put it in 4wd low range in 3rd gear and let her rip.

-

From 24 valve to 12 valve

I put a quart in sometimes, I noticed it quieted the pump down a noticeable amount.