Everything posted by Silverwolf2691

-

Dash Indicator Light Replacement

Leaky88, dont know what color you picked for the illumination lights, but you will have issues with certain colors showing. If its blue, your needles, redline, and red tick marks will not illuminate well if at all. Any other color besides a blue or green and the regular tick marks might not show up. Just want you to be aware if parts of your gauges dont light up like they used to. There is a way around the above issue but its labor intensive and is a bit of unknown territory. You can use stage lighting gels and cut them out to match the color you want and keep what you need, but you need white leds to illuminate it. For reference: https://www.cumminsforum.com/threads/diy-changing-gauge-cluster-color-using-lighting-gels-lots-of-pics.455003/

-

Help, looking for comparable trucks for sale… insurance co is not even close

yikes. That's almost watching the needle fall as you drive territory

-

Dash Indicator Light Replacement

@Leaky88, do you have the green odometer or an LCD display similar to a calculator? I swear I've seen in the crossover years (98-99) that the odometer is different than the green ones like most others have. It would also make sense that the owners manual only shows one row of digits and no Cruise indication on it, and Trip is in the "wrong" area. I wonder if when Dodge went to the green vfd display, that they also swapped those indicator bulbs to LEDs. I would only need the 7 illumination bulbs, a high beam bulb and turn signal bulbs, and one other I think, cant remember where, to convert my cluster to LED. Also what would have the reasoning on the green cruise like stanley's vs the amber cruise like mine and dripleys when in the odometer area? Especially when my 2001 1500 I used to have was green but my 2001 2500's was amber..

-

Help, looking for comparable trucks for sale… insurance co is not even close

US $23,461.70 for your trucks selling price, US $22,770.00 for the v10. (as of 07/06/21) V10s get about 9-10 mpg (26.13-23.52 L/100km) whether towing at max or just driving on the road. Was looking into getting one, but I liked the Cummins better. And there is less aftermarket power upgrades available for the v10. Biggest thing is they are choked down on airflow in and out. 488 cubic inches likes to breathe and in factory form they breathe through a straw.

-

VP44 1998.5 Eyes Burning, Bad Mileage Help

Whelp, that explains a bit more. Learned something new this morning. That explains partly to mostly why too advanced can/does cause the bucking/surge in cruise state.

-

VP44 1998.5 Eyes Burning, Bad Mileage Help

I need a refresher, the vp44 has 0-30* of timing, is that before or after top dead center? Because when I think advanced, it's after top dead center...

-

Head Leak

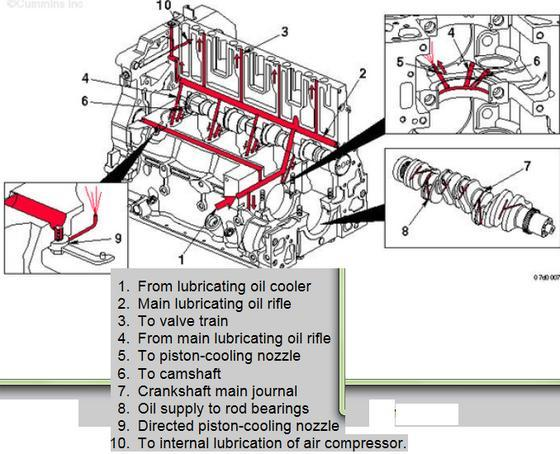

On that last photo, the oil spots look spotted like they were splattered onto the fan hub bracket. The closest oil gets in that area is the timing case below and the oil cooler that the filter is attached to, but that's behind everything. You cleaned the area, but I think it might time to wipe down the side and front from top to bottom. Get everything dry and oil free then go for a drive to see what's leaking and where. Another thing you could do is stick the phone camera down in that area, just above the water pump, and snap a photo. You would be amazed at how far liquid moves when on an edge. I don't know what's behind that pipe plug, I think its coolant because there isn't any reason for the oil to be there. And the rockers get oil up from the cam or "oil rifle", forget which. Wanted to design a billet wet block Cummins, was doing the research and needed to figure out how oil and coolant are moved throughout the engine. Best approximation in photo.

-

Quadzilla timing and sled pulling

Morning Everyone, I downloaded the tune builder to play around with it and see if I can improve my sled pulling tune. Well after re-reading the how-to for tuning and having the visual of the graph for the low PSI timing reduct, I realized I had the the functionality of it backwards. I thought at 100% load it would be pulling all of the degrees you specify, not what it actually does, which removes timing based more load. I've read that tuning guide, and some of the other ancillary threads that Mopar1973man put up, and it never clicked/sank in/stuck as to what it was doing. So that leads me to how all of this relates to pulling.. When I am sitting at the line spooling up, all it is is to bring rpms up. There is no way to put a load on the engine like an automatic without slowly releasing the clutch. Because I am not running a clutch meant for sled pulling I don't sit on the clutch. Its a rapid, smooth-ish release to try to minimize cooking the disks. So I go from a light to moderate load to 100% and nearly full throttle in less than a second. This kind of negates the low psi timing reduct in this situation. So that kind of leads me to a couple questions: How low can you pull the RPM timing max sliders? During regular driving my truck likes being down in the 8-11° range when taking off, but that's at 12-1500 rpm, not 2200-2750 rpm. My 397 foot pull I have a data log of. When I took off, I was spun up to 2300 rpm then got pulled down to about 900, then got some boost and fuel and the rpms shot up to 3200-ish. I don't remember what tune I had for that one but timing bottomed out around 11. Depending on how my truck continues to behave, is it worth keeping the low psi reduct or just pull the timing sliders down as a whole and put the reduct to zero? Or am I overthinking this? End goal is to get a decent amount of take off power without dragging the motor down while I save for a pulling clutch. I attached the data log for the 397ft pull I had back in October. The video is on the last page in need help deciding on a turbo thread or on YouTube. 10102020.xlsx

-

VP44 1998.5 Eyes Burning, Bad Mileage Help

My brother had a similar issue with the smell and burning eyes with his truck. Turned out his ppump needed an overhaul. Needed machining too apparently. Dont know/remember on what but I think it was in the governor spring area. If the VP44 failed advanced or retarded, not sure which, I think retarded, it could also have the unburnt smell and the lower power like you described. You might have joined one of the unlucky few to have a VP44 fail without a engine code. Depending on the state of your lift pump when you swapped it and if/how long it couldn't produce the proper amount of fuel, it might have munched the timing piston. Injectors are another possibility, popping too low due to wear and tear. When the engine is at an idle can you tell us what the engine load is? It's the readout just above coolant temp in the photo above. At an idle, if its below 5% you should start looking for new injectors. If its around 0-1, you need injectors pronto. the other sign with out the scan tool is your idle speed. If its higher than like 875 ish RPM, the injectors are shot and need to be replaced. This is end stage though, you wouldn't know they were going bad prior to the raised rpm unless you had a scan tool

-

VP44 1998.5 Eyes Burning, Bad Mileage Help

Just remember to subtract your altitude's air pressure (14.7 at sea level) so ~4-5 psi with that 18-19 psi, if you are at sea level.. With pressure gauges, you have 3 types: psia - absolute pressure, includes the pressure of the atmosphere in the reading. This is what the MAP sensor is reading. psig - gauge pressure, 0 psi is atmospheric pressure, anything else is above atmospheric pressure. this is what our boost gauges are. psid - differential pressure, pressure on one side of something against the other side. Usually upstream and downstream of a filter. This is part of how DPFs know when they are getting full.

-

Turbo Help

not adding info buttons but changing the names from say: TPS pump maximum to Wiretap maximum TPS/max throttle TPS pump minimum to Wiretap minimum TPS/min throttle Minimum pump tap fueling percentage to off idle wiretap pump low boost scale psi to wiretap boost minimum/boost low limit (not attached to the phrases, open to suggestions) Just saying make it a bit more user intuitive as to what you are adjusting. Also, to be clear, I wasn't asking if you specifically could do it, just if it was easier than doing a program redo like you mentioned in the thread I linked above. I don't know programing, so I don't know what simple to ask for but is actually program breaking or start from scratch paths there are.

-

Turbo Help

To the best of my understanding: Max load offset is your "tip in" timing pull while moving. When you transfer from cruise state to performance state, you need a timing pull to help spool the turbo up. Low psi timing reduct is your acceleration timing pull to help spool the turbo from a stop. Uses TPS and boost to calculate the pull. Also only used in the 0-10 psi range. nothing like a 10 page dig for that lol. Slightly off topic but I think that those two settings are the biggest wall to anyone who is just starting out with the quad. That and the verbiage used to describe the settings. @Me78569, I know you haven't worked with the quad for a while, and adding info buttons to the app is a major restructure, but what about just changing the names of the settings? (the white text you click on to open the field to enter your numbers) I have a couple ideas for changes but not for everything.. Unless it was intentional to get people to slow down and actually look at/into what they are changing...

-

Turbo Help

Half of the timing but maxes out at 50% Throttle. For example, low psi is 5*, scaling is 50%. When you accelerate, you will pull 2.5* of timing max by 50% throttle.

-

Help, looking for comparable trucks for sale… insurance co is not even close

FB marketplace for the Northeast is all over the place. 11k to 25k. If its over like 300k miles or rotted you are down to the low end. Under 150k and clean its 20-25k.. and proper "clean" around here is zero rust. If it starting to show rust people still ask 15-20k depending on milage. People are brutal on both sides in regards to rust with second gens around here.. When i was looking for my truck there was a 94 with 400k miles but not a clean panel on the truck, nearly fully peeled clear coat, black paint was now grey, and the lower part of the truck was nearly gone.. still wanted 4 grand for it.

-

front ball joint time

Being you are land locked, what humidity went with that? Northeast is in a heat wave, the metorlogical definition of above 90* for 3 days.. cooler than a lot of you but still, but its only about 90* but with 70* dew points.. Only gone as far as Florida and Virginia for south and up to Maine for north. Never been out west. Curious about how the climate is out there.. My brother went to Vegas and it was 110-115 but he said you never felt the sweat because it evaporated so quick. Back on topic.. All this and the joints are neither parallel nor inline with their counter part. Exaggerated it looks like this I believe: / \ I I Supposedly they are also not much larger than a cj7's ball joints. Because of the fake kingpin like design i believe that is part of the reason that the lever under the tire for up and down movement is a false indicator for the top (i think?) Ball joint.. @Mopar1973Man (<-- cant delete.. sorry Mike!)

-

Turbo Help

Those are similar to what my truck likes. Need a bit more and faster timing pull with timing reduct and scaling, Especially with a larger turbo. The cruse is whats best for your truck, i have 4.10s so i have to add a lot of timing to my truck to get good mpgs and low egts on the highway.

-

front ball joint time

Currently have Synergy ball joints but they are discontinued i think. Still going with no play after 5 years now. Next round will be EMF ball joints, rebuildable on the truck, and adjustable. $510-ish from Genos includes all 4 plus all tools (minus the press) to install and adjust them. @dripley, you might have caught the tail end of good moog stuff. Any second gen 2500/3500 that has the slip on style brake rotors are known for munching on ball joints. Seems to come down to the design of that version of the Dana 60. (Unless you are like Mopar1973Man and build around longevity of parts). https://www.cumminsforum.com/threads/interesting-info-about-00-02-ball-joints.475650/

-

Need help with tune or injectors

I have the setup but the rubber coupler from turbo to tester is too short to hold on very well. Blows off between 10-20 psi depending on what i use to tighten the clamps. (Screwdriver or ratchet)

-

Turbo Help

You can still get it to run but its gonna take a bit of tuning with the quad and probably the boost elbow.

-

Turbo Help

He351w is different than the he351cw from a later 3rd gen. (Same wheel sizes/not true after digging up @LorenS's thread. He341 compressor wheel with he351cw turbine) but 12cm^2 exhaust housing with 5 bolt flange instead of the he351cw flange. What are you running for tunes with the quad? At full spool at max level are you seeing a slight hazy trail of smoke? Also because i have to do this as well.. have you checked for boost leaks? I know it takes a large amount to cause this amount of boost loss but it doesnt hurt to check

-

Head Leak

If I remember correctly, the OE Cummins head gasket had an issue with the front corner where the thermostat is. But they revised the gasket and corrected the issue. I think there was not enough sealing in that area in regards to the gasket material. Been a while since I did mine. FWIW, mine leaked directly above the oil cooler and below the thermostat area.

-

Turbo Help

no adjustable elbow from the looks of it.. also from what calibrated says its a 64/67/9. Or 63/67/12... The video on their website says 63/67/12.. The product description is vague as hell too, but does mention a 9cm^2 housing..

-

Brother's truck, drivers door functions and brake lights dont work

Luckily it was an easy fix. Under the dash where the large bolted in connector is, there is a second smaller "normal" style connector that had come loose. that fixed everything but the brake lights. Turns out he blew the fuse under the hood. Such a simple fix for the windows that cost him an inch of water in the truck..

-

WHERE TO DRILL A CC/SB 4WD 2500 2001 FUEL TANK FOR A SUMP? WHAT BRAND?

I stand corrected.

-

Turbo Help

Yeeeaaahh.. you should be seeing a lot more boost. 25psi is stock HX35 range. Before spending money try clamping off the wastegate line. Then get an adjustable boost elbow or similar.