-

Anyone here run Gloshift gauges?

I've gone through a few of gloshifts gauges over the years. I got maybe 2 years out of my last one. When I bought my truck, it had a boost guage, trans temp guage, and the pyrometer, all gloshift.. All failed within the first year of owning the truck, but they were "cheap", so I bought new ones to replace them. When I bought a new boost gauge, it rattled upon installation, so I sent it back so they could "test it". They told me nothing was wrong with it, that it was the location in the intake elbow that was causing it to rattle, and I would be charged more for shipping it back to me. I refused to take it back, so they charged me the bull crap restocking fee and I only got some of my money back. The guy was a double, but I was young at the time, so I didn't really stand my ground. All in all, horrible customer service, cheap quality. My second set of the other gloshift gauges failed a couple years after replacing. I've had a isspro fuel pressure gauge installed shortly after I bought the truck 10 years ago, and it still works great, and that's without a snubber valve on it...(I need to get that installed) It may cost more, but it's worth it in the long run.

-

Replaced track bar, steering wheel is now "off"

I know when I changed my track bar 6 or so years back, just a non adjustable moog, it was longer than the one originally on the truck by a solid inch. My steering wheel needed to be re-adjusted as well. Re-replaced the moog 2 years back, no adjustment needed.

-

Rino lining or line x rocker panels and outside lip of wheel wells

For whatever reason, it keeps flipping the picture upside down, but oh well I did mine about 8 years ago, line x, with the protective uv coating. It's held up well for the most part, but the prep work is definitely a must. I had them redo a bunch of it last year because they didn't do a good job of prep work (the plastic cap along the fender well for the liner, they just went right over it instead of removing it to spray to the metal. But they fixed it free. Ended up having to peel it all off to do it right. The guy even said he remebers the truck, and that they've come along way since then, and that they used to cut corners.....really?? Make sure to check it periodically along the top and bottom to make sure it is not peeling away from the metal of the truck. Mine was also doing this in spots along the wheel well. If you have them do it, ask about warranty, and what they do for prep. The store near me is lifetime warranty, but the one in Spokane is not.

-

Head Leak

Thanks for everyone's help. I'm hoping this will buy me a few years, maybe even more. The head should hopefully be the next big thing to be done.

-

Head Leak

So I got to sealing it this weekend, and so far, it is holding. Crazy how much oil was sputtering out of there, enough to leave decent size spots on the ground. If it starts leaking again, I'll take the water pump and fan off to get at it better, because those things were a hassle to get around. Does the fan come off easily by just removing the 5 bolts that hold the bracket to the block?

-

Head Leak

Would the ultra black rtv work just as good? Or just the ultra grey?

-

Head Leak

Well I'm hoping som RTV will be enough for now. I dont really have the time or place to tear the whole front of the motor down, nor the confidence really, especially pulling the cam out. And being without my truck isn't an option either atm. But if it doesn't work, only one choice left... Plus a head gasket leak that will have to be addressed sooner or later.... But I saw from others who were leaking from. The same place same the same thing about the gasket, it some how gets pulled inwards and then they develop a leak.

-

Head Leak

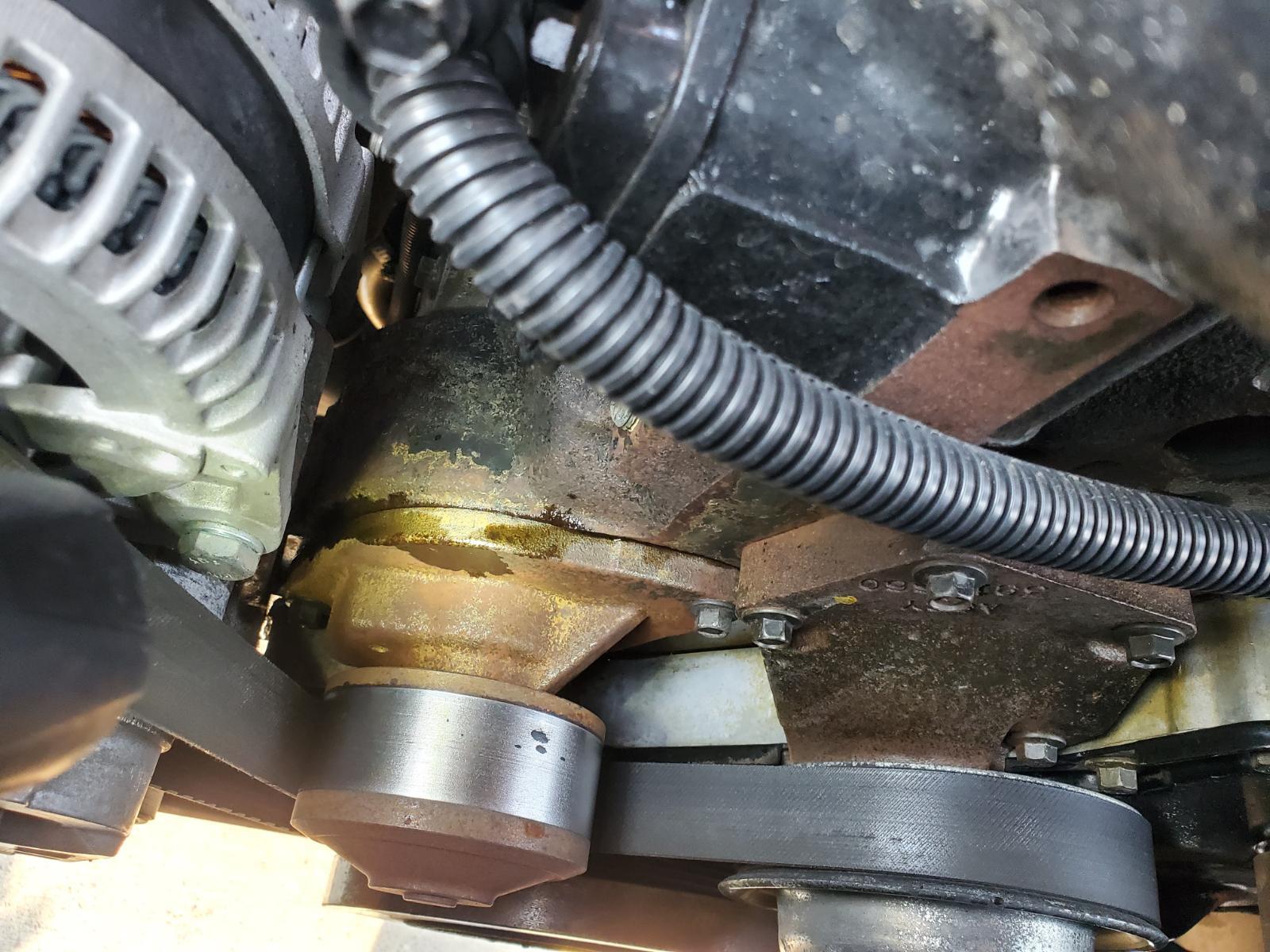

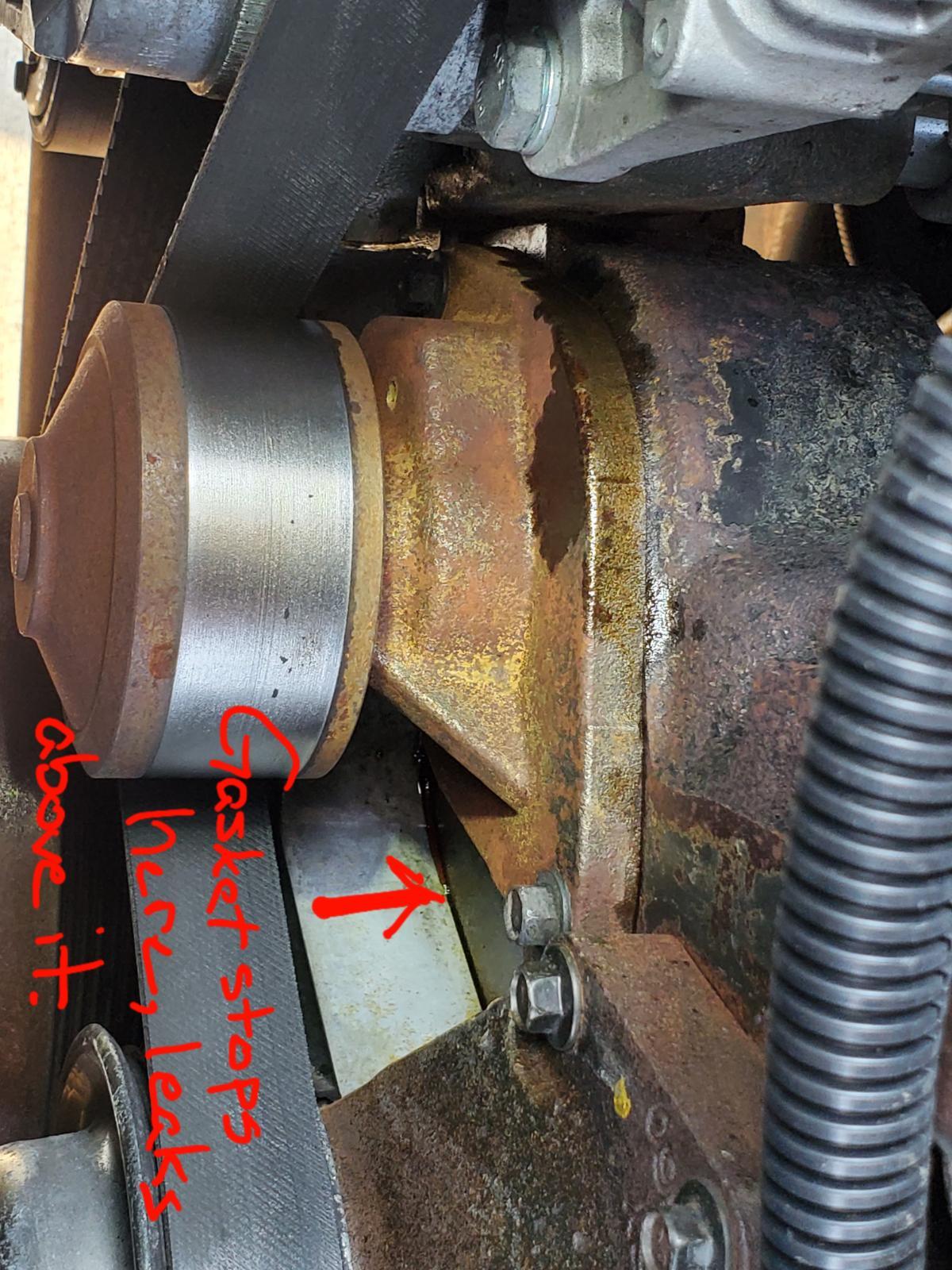

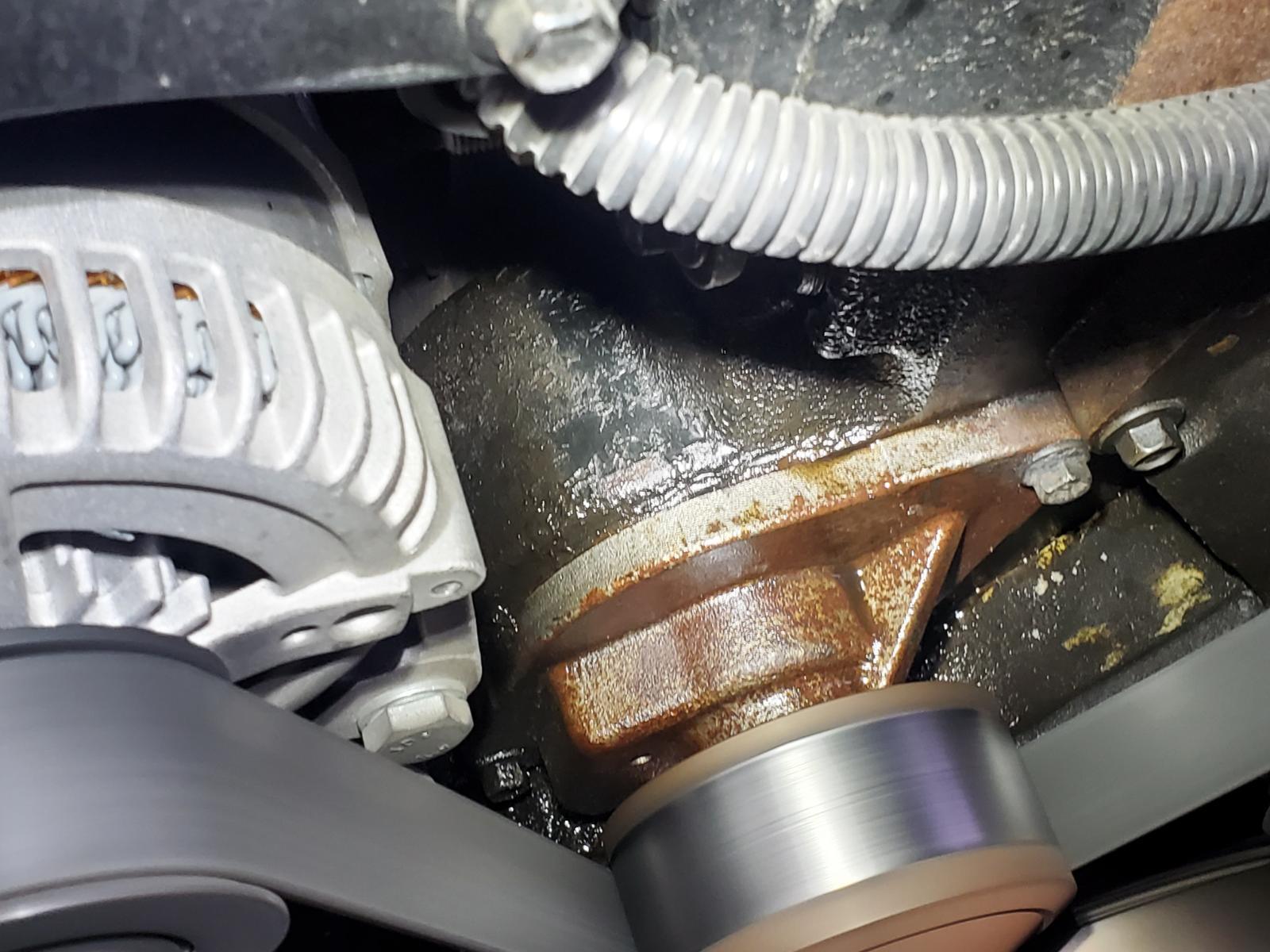

So I finally got a day to clean the front of the engine off. Greasy! And I think I found the leak.... Just underneath the water pump. Close to the fan pulley. Went for a 3 mile drive and it went from clean to this.... Why does the orange gasket just stop abruptly here? The oil is coming coming from above it... And the wet spot on the water pump is oil....is it being blown up there from The fan? There isn't an oil gallery behind behind water pump right? Could I maybe get away with caulking it for a time? It seems to be leaking more than I did now that it's all clean.

-

Head Leak

So I've been keeping an eye on the leak, and it's definitely got worse, it will have a half dollar wet spot on the ground in the morning. What's weird, it seems to be coming from around the water pump? I don't recall an oil line from there. But I cleaned off, drove 10 miles, and looked, and there was oil sitting on top of the water pump, and that was the wettest area...here are a few pics.... And this is after I cleaned and went for a drive.... It looks like it's seeping from around the water pump housing? Everything around and above it is dry....

-

Head Leak

Must be the year of head gaskets, because mines leaking as well, but im trying to hold off a little longer so I can be without the truck for a time. But I'm not sure if I'm leaking from another spot in the front as well? There is a plug that is underneath the thermostat housing that seems to be wet, even after driving a while. I know it's leaking above it, but that evaporates during the drive, while from the plug down, it doesn't. I can't tell if there is coolant leaking from the waterpump as well. I wipe it clean, start the truck, and I can see coolant coming up around between the pump and block, but that could be trapped coolant that is coming up between the two due to the engine vibration. On top of this, I wiped the area down last night, and when I went for a drive and came home, checked again, and it seems like I have a oily film that was sitting of the housing of the water pump? Not much, but not green like coolant. Could I be getting some oil to come out from the head as well where it is leaking coolant? Is there a oil gallery there? (Passenger from) No oil in coolant, no coolant in oil either (just did oil change sunday) The gear case is wet with both oil and coolant below the water pump, and seems I'm leaking a little oil on from the gear case next to where the fan bolts to the block... I went through some of the bolts on the gear case and found a least one that was very loose, so maybe that's contributes to some of my oil leaking issues

-

Blown Head

Your first head gasket blew because of a lack of coolant changing?

-

Steering Issues/Cold Weather problems

@TractormanI can turn the steering wheel a little then it stops. I hang my head out the window to see tire movement, the tires barely budge. I'll check the mountings around the hydroboost, see if something needs tightening up. Go from there. As far cold goes, Idaho is kinda on the edge of this polar vortex. I'm a few hours north of moparman, and we haven't hit zero yet this year, suppose to start warming back up into the 30s by mid week

-

Steering Issues/Cold Weather problems

I can't say with certainty that the hydroboost is free and clear of debris, but the powersteering pump is brand new, and I bled the crap out of it before reconnecting the return line. It only hums and buzz' when it drop to single digits. Other wise it's quiet. Only time I've hear synthetic being a issue with seals is when you've used conventional oil for the life of a vehicle and then decided to change to synthetic. Even then, I didn't really see that problem on my 93 Dakota. @Tractorman, so what I'm understanding is that the weak powersteering pump issue is normal? Maybe the relief is just set lower or something?

-

Steering Issues/Cold Weather problems

Pumps not even a year old, was it just garbage from the start? I'd think the synthetic would work just fine, would there be a difference between normal and synthetic fluid that would affect the way the pump would work? I haven't replaced the steering box, just the powersteering pump. The humming lingered for a bit, probably 5 min. plus, even after a short freeway drive. About 8° F this morning

-

Steering Issues/Cold Weather problems

I'm sure most of us are experiencing cold weather one way or another, and so I'm curious if you have had any problems related to steering/ hydroboost issues. Whenever it gets to the low teens or single digit temps, I start the truck in the morning, and fires right up, and you can hear and feel loud humming vibrations in the cab. It gets loud if I touch the brakes or turn the steering wheel, and you can definitely feel it vibrating through both. I figure something maybe with the hydroboost. It had been doing this for years, and I thought maybe a new steering pump would fix it, but it didn't.(needed to be replaced anyway.) Anyone else experiencing this issue? Going to the steering issue: I replaced my steering pump last spring with the one from genos. From day one, it felt under powered....but I thought maybe it would get better with time, maybe a little air in the system, despite a thorough bleeding and following the steps to get the air out.(also new lines to and from the the hydroboost. Even disconnected the return line from the steering box to get ALL the old fluid out.) Sitting in my truck now, operating temp and all, I cannot physically turn the steering wheel while the truck is standing in place, the tires won't budge.(265 75r 16 Michelin Defenders) I have to be moving ever so slightly to get some assistance to turn the wheels (increasing rpms does nothing to help either.) Does this sound right? this issue isn't because of cold weather, but it probably makes it worse. The pump has Redline full synthetic powersteering fluid in it. Here's the pump. https://www.genosgarage.com/product/BORG-800328/power-steering-pump