Everything posted by Silverwolf2691

-

2012 Range Rover...... not foreign to me but a right POS

LR = Land Rover RR = Range Rover (90% sure on this one)

-

Isspro fuel sender

3/4 inch to half inch is what i have too. Cant seem to upload a photo from my phone. Possibly too big? Server error -200.. I think one of the fittings is loose for the fuel leak. And an oil leak from my vacuum pump..

-

2012 Range Rover...... not foreign to me but a right POS

@JAG1, Large amount of intake manifolds are plastic. Valve covers too. All post 2003? Hemis, LS motors, the EcoDiesels (dont start me on those. Had one. No issues but stupidity abounds with those motors), most of the V6's from Dodge I think.. All plastic intake manifolds. All in the name of thermal efficiency, weight, cost, and emissions. Unless I'm missing some sarcasm...

-

Isspro fuel sender

Could it have been too loose? If the belt was rounded off on one side only, could that have meant that the belt was skipping over the pulley teeth?

-

Isspro fuel sender

Cant see the photo either. The belt tension is definitely loose on the GDP Fuel Boss pumps. Never had a belt thrown in 4 years/18k miles. GDP also says their belts should go like 50-75k between changes. Speaking of.. I need to check where a fuel leak is coming from around the fuel pump.. might be the hoses, might be fittings, don't think is the pump halves seal. Especially since I have my first pull of the year tomorrow..

-

I'm Back, Finally! And I have some good questions/ topics

@dripley, I had both issues with my ram 1500 I had before I had my 2500. From what I remember when I researched it then, the CTM controls the timing of the wiper motor based on the signal from the multifunction switch. My 1500 would have them start in the normal park at the bottom of the wipe path, set to intermittent and would make one full pass then stop after starting back up the windshield. Also only had one of the 5 intermittent settings, didn't matter the position on multifunction switch. The other symptom I was having was the wipers wouldn't park at the bottom of the windshield. If you turned them off in the middle of a wipe that was where they stayed, similar to turning off the ignition mid wipe. only way for it to park was to put it to constant low or high then all the way off, no stops. @Stanley, I don't remember what extra was controlled by the highline CTM, but I seem to remember the overhead trip computer and possibly keyless was with it. You shouldn't have to swap any wiring in the doors if you have power mirrors already. Also you might have the plugs already if you had an SLT with no power mirrors. Unless you had one of the base base ST trim levels with no power anything. My 2500 was nearly an SLT+: overhead computer, power seats, keyless entry, power locks/windows, but no leather/heated seats/power & heated mirrors. All the plugs were there so just a matter of getting required items to plug in and I was set. Also, yes, that is your base CTM. Seems I over (under?) stated what was controlled by the base CTM.. http://starparts.chrysler.com/tsb/en_us/dto/pbd2/08/00/22/080022dc80c84c7a.pdf According to a quick look with professor Google, you cant swap base and highline. Apparently, dodge got picky with the wiring harnesses. if you had a base you cant upgrade because unlike the doors and some other areas, the highline wiring is just not there. https://www.cumminsforum.com/threads/central-timing-module.556384/ this guy did a cab swap, didnt end the best because of the CTM https://www.cumminsforum.com/threads/1999-st-with-no-security-ctm-issue.2056105/

-

I'm Back, Finally! And I have some good questions/ topics

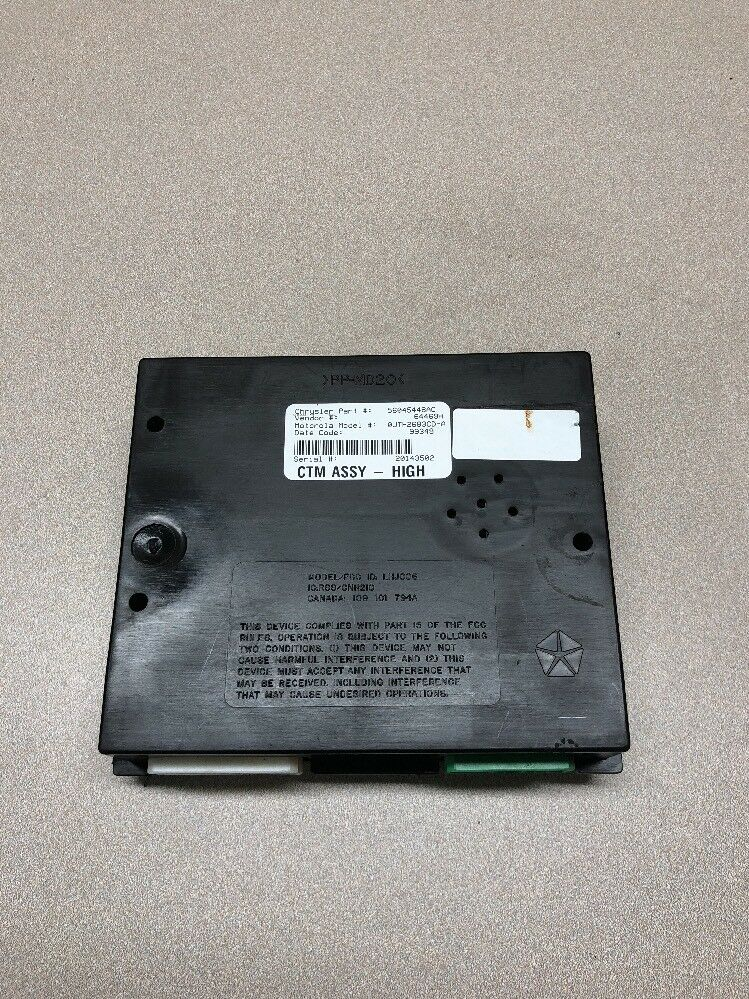

I goofed on the photo.. those are bcms I believe for newer trucks. this is the high line module for a 2001. This should be a base ctm. previous post's photo I believe is also correct for the base ctm only.

-

I'm Back, Finally! And I have some good questions/ topics

If i remember correctly, as long as the part numbers matched you should be able to swap them without issue. There is the base and highline ctm. Pretty much if you have a non power anything truck its a base ctm. Anything more and you get the highline one. The swap is just a connector or two and two screws (i think). But its behind the right hand side of the knee bolster, behind the plastic.. its not hard to get, but it was just one of those position is so awkward it makes it hard to do. If you can get to it, base ctm is small, highline is much, much larger. In attached photo, highline (approx, pictured is a dakota) is the "60 day warranty" photo. Base is below it. This is what i remember from 6-7+ years ago.

-

I'm Back, Finally! And I have some good questions/ topics

From the link you posted, it doesnt come with the vents so you would have to reuse your old ones. This sounds like a bad CTM. Its a bit of a pain to change due to its location but if you have the dash out, you might get to it a bit easier

-

I'm Back, Finally! And I have some good questions/ topics

My brothers truck received an LMC dash and bezel. Felt good coming out of the box, Pattern was an almost match. The color was like 1 shade off if I had to nitpick it, but tbh, its not really noticeable. The bezel looked damn near identical to the factory original one. Fun fact, when you drop some pieces of the cracked original dash they can shatter like glass, and sound similar too. I have pretty much the same headlights MoparMan does, projectors from Retroshop. By the time I priced out a sport upgrade/relay kit for my brothers truck recently, it was within range of the projectors. Don't get me wrong I love them, but I feel like their long range punch just isnt there. Could be a product of my surroundings, lots of tight, winding, no shoulder, car-and-a-half wide middle of the woods type roads that could be bouncing so much light back that it visually drowns out the long range light. Depends on what you are looking for, they have the clear and smoked versions not sure about the amber ones. I like my OEM amber ones and I just put leds from lasfit in them. They light up speed limit signs at night because they are so bright. I've used 1AAuto. The actual 1AAuto brand mirrors are good, I'm not the happiest with the other brand that they had. Got a set with turn signals and first rain we had one of them was filled with water. Didnt return then because I was out of the warrantee period, I waited to put them on.. Have a BlueTop box, no issues with it. Never had a RedTop. Supposedly the guy who owns BlueTop used to work with RedTop, bit foggy on that so take with a grain of salt. Not sure on the power locks, but depending on what the wipers are doing depends on what it is.. are they parking in the middle of the windshield when on delay? My previous ram 1500 and my current 2500 both had and have that issue, CTM took care of it on the 1500, havent fixed it on the 2500 yet. How was dealing with DOR? I have their track bar. Didnt have the issues most were complaining about back almost 4-5 years ago. Not sure about the sway bar mounts..

-

Front end popping noise

To be honest, I've only had a few instances of wheel bearings going bad, but I've never had them make a popping noise. Near constant grinding, howling, thumping, growling, yes but not popping.. Unless because sounds are subjective when it comes to cars, that we are talking about the same thing. If it was a "true" popping noise, I hope you replaced the u joints on the axle shafts. but usually those are a slight crunching when turning in 2wd, and loud crunching popping noises when turning in 4wd.

-

VP44 Injection Pump Teardown - How it Works

@Mopar1973Man, when you took the pump apart, did you see the ziptie in the banjo bolt hole while setting up that photo? I want to take one of these into work and hook it up to one of our test stands and see what happens when you spin the input or just see what happens in general

-

VP44 Injection Pump Teardown - How it Works

The one next to the supply inlet? I thought that was the entire reason for the recommendation over the past what, nearly decade?, for the 14+ psi inlet number that MoparMan had discovered.. The supply goes right past the overflow valve. The other thing is i cant imagine that vane pump pushing that much.. we wouldnt be able to run normal air dog or fass pumps. The air dog 220 is 220 gallons per hour not gallons per minute. 220 gph is about 3.5 gallons per minute. Other thing is the open area of the vane pump doesnt look very high capacity. (I'd like to amend previous paragraph, its late and an interesting night at the fire dept monthly meeting/annual vote, i misread the flow figures from mopar-muscles post. Read gph as gpm... ) https://www.cumminsforum.com/threads/bosch-vp44-101.1839897/ Looking at some of these schematics, maybe we are both wrong because the first one shows the over flow valve is only on the return for the distributor needle valve...

-

VP44 Injection Pump Teardown - How it Works

Thats why i suggested the vent valve. Open from 0-5 psi for example, then closes above that. That leaves the check valve that is already there to take care of eveything else. No wiring (beyond making it run after shut down) no thinking about it. Problem is my company wouldnt make a single valve for a price that people would like. But we are proud of our quality and tolerancing and thats why our customers keep coming back. Btw, @LorenS, nice job on the hydraulic schematic.

-

VP44 Injection Pump Teardown - How it Works

@Dieselfuture, nice rx7. And 12s @ 112 mph is nothing to sneeze at. Usually tuner/imports i dont like because of the fart cans most use for the exhaust. But rotarys (especially with a race port or bridge port) and neon srt4s get an exception in my book. Both just sound awesome. @W-T, I dont know why but the forum "sentence" on my post was supposed to be a link with a whole bunch of teardown photos but i copied the address and no hyperlink.. Man the reality check of forum posting is a bit wierd.. its 10p eastern at time of posting but for a bunch of you guys on mountain (8p) or pacific time (7p) are just sitting down to dinner, finishing dinner, or what not.

-

VP44 Injection Pump Teardown - How it Works

Disassembled A Bosch Vp44 Injection Pump - Page 3 - 2nd Generation Dodge 24 Valve Powertrain - Mopar1973Man's Dodge Cummins Forum ^ The article/forum thread I was referencing earlier @W-T, this is what I was referencing in my post about the extra return port. (would have the port in the top side (engine side) of the skinny and deep chamber, that way there is flow across the whole psg) Supply is the right boss and ofv is the left boss. Where the zip tie is coming out of doesn't seem to be closed off (via psg) to the area below it in the skinny and deep chamber. But it seems like there would be no flow circulating in that area because the ofv would bleed any extra flow and pressure off before making it into that area. Essentially making a deadheaded area. I just don't know what pressure this is actually at, whether its at lift pump (~14 psi) or vane pump pressure (100-300 psi). I'm just going to put this here.. I could be totally wrong about this.. I only know what I know due to searching on the web, looking at the disassembly thread, and watching the YouTube video I posted earlier. If I am wrong, I apologize in advance and am willing to be corrected. @Me78569, taking what you said into consideration as well, I just feel like the inlet port and the vane pump are limiting factors.. we have a 3/8-1/2 inch line and we feed all that fuel into a 6mm (I'm guessing) hole in an m10 threaded banjo bolt adapter that goes into the pump. There's only so much that is gonna be pushed through that small of a hole. The vane pump also moves what visually looks like a small amount of fuel. The smaller cousin of this is a vp30, its a 4 cylinder pump instead of 6 and used in the UK. Those have been tuned for 4-6k rpm (i think) by the tuners across the pond. However they are used on smaller engines so that plays into everything as well. IDK, I'm just frustrated that the vp44 is just passed over with everyone just saying "..the vp44 is just going to die on you and leave you stranded and cant make power. Just ppump it.." my brother has a ppumped 24v that he bought that way and yeah the pump is turned up a bit and has some size bigger injectors than stock, but if its below 40°f outside it doesn't like to start, even cycling the grid heaters. mine will only start protesting if its below 10°f and no grid heaters, even then its a slight stumble and then full running. My truck is also a lot more drivable in the rich parts of the town I live in because I can turn my power down, my brother has to drive with an egg under his foot to not cloud everything in soot. There feels like there could be more potential left in the pump, but I'm sure it was given up on due to lack of interest and/or funding or client base.. Jeez im starting to sound like a rotary (Mazda) owner.. from factory tuned to a razors edge. But lack of care and knowledge on the owners part has caused them a lot of problems. The diehard guys are looking for more power and it essentially boils down to: bolt ons; max of like 15-20hp gain. [wire tap tuner] Want more? well turbo or supercharge it, but your engine life just got cut by a significant amount (greater than or equal to like 50% or something along those lines) [Monster pump mike vp44] . After that it becomes make your own billet rotary motor [the never been made, to my knowledge, billet vp44].. I wanted a Mazda rx-8 when I was younger, research yielded that my 19 year old butt couldn't afford it if it popped a motor.

-

Front end popping noise

^^ This. There's a way to use the steering to force the bearing out too. Need something to fit between the stub shaft yoke and the axle housing. Round bar stock or an extension on a socket has worked. A friend helps here.. hold in place on the yoke, start engine, turn the steering wheel into the "spacer" so it pushes the bearing out. Even on semi rusted stuck bearings they popped right out.

-

Front end popping noise

Usually a grinding feeling/sound with a slight vibration. Its harder to feel in my opinion in these trucks i think because of the weight on the front end, at least compared to my cherokee and 1500 i used to have

-

VP44 Injection Pump Teardown - How it Works

I have hard the same thing.. if i had to guess its the vane pump. No engine turning, no fuel moving (usually)

-

VP44 Injection Pump Teardown - How it Works

and here I am trying to figure out why the vp44 cant fuel for high rpm power.. most people say that the plungers cant fill fast enough, but they are supplied with 100 to 300 psi of fuel inside so I dont think that is it, at least not totally.. Then theres what @Me78569 found with the quadzilla testing, that the ecu is putting out a full stop runaway protection signal to the vp44 after 3500 rpm. I swear theres a market for something similar to the smarty but able to futz with other things besides fuel and timing. Turn off or raise overboost code limit, raise runaway protection rpm, stuff like that.. But if I had to guess Smarty has a monopoly on the obdII flash style tuning. Meaning cease and desist sales of said fictional programmer.. Sorry, slight sore spot from the piles of limits that people say about the vp44.. Alright off the soap box.. I would say it would be better to have a second return port above the larger opening where the timing tone wheel is. I say this because the ofv is only shortly down the inlet so only half of the board would see moving fuel for cooling. I'm referencing a few photos of the vp44 disassembly article that @Mopar1973Man did.. how to achieve this i dont know off hand.. but i might have an idea.. My work has a vent valve. Essentially its a poppet with the spring on the down stream side keeping the poppet off the seat. When the pressure gets high enough the poppet closes and blocks off the flow. If it was set up to shut off above say 20 psi you could flow after shutdown then when it builds pressure in the timing chamber after startup (if im understanding/remembering how it works correctly) it would shut off flow and keep pressure in the vp44. On shut down the valve opens and allows flow for cooling.

-

VP44 Injection Pump Teardown - How it Works

I might be able to help slightly with that.. Fair warning, 25 mins long and not in english but the auto translate for closed captions works well enough.

-

Isspro fuel sender

51506 Custom Fuel Pressure Regulator (fuelab.com) (was supposed to be a link) Just incase you continue down this route, I believe this is the part number that I got, except I got mine through summit I think. I can double check when I get home. Fair warning, moderately expensive.. I think it will be a bit easier to order on summit than their new website.. Really confusing on how to select your options for a "custom" regulator from them. Just need the 10-25 psi range.

-

Isspro fuel sender

@Red Rambler, I have the GDP Fuel Boss as well, hooked up all mechanical. With the check valve/fuel pressure regulator that they sent me I was barely pushing 14 PSI driving down the road. I had to nearly tach out the rpms if I wanted much more in terms of PSI. I have since replaced the check valve/regulator a few years ago now with an actual fuel pressure regulator from fuelab. I have it set a bit higher than I should at 22 PSI, but it never moves from there unless the fuel is low (1/8 tank or less) and after being run for a while, so warmed up fuel being thinner. Only other time is when its really cold, my gauges start reading a couple psi higher than usual. (Southern New England winter, 5° above in the daytime/-10° at night is a deep freeze for us). I never liked the brass check valve because that's what it is, a check valve. Granted add a bit of preload to the spring and it wont open right away but its not designed as such and I think that's why we get fluctuations and what not from that set up. Spring design isn't correct for relief service and/or force balances/area shift are out of whack with the poppet. I work at a company that specializes in microhydraulics (smallest insert in my group is Ø.187 OD and more stuff goes inside) and our pressure relief and check valve divisions are different, partly from order volume vs cnc machines, but also because the math for the different designs is somewhat different.

-

Squeal and jump

When we rebuilt the t-case in my brothers jeep i believe we used a master kit from jbconversions.com. You have to look under np241c though.. There is a build guide in the article section on here i believe. The only hard part is there's 2 different input bearings across the years. And not a lot of info about what has what. One is a single row bearing, one is a dual row bearing. Its not hard to do the rebuild, should be a weekend if you have the rebuild and all the tools Ive had to look for the same stuff because the rtv on my case failed and its starting to leak between the case halves, so if im taking the case apart with 210k on it, i might as well rebuild it. Especially since i ground the 4x4 synchro, or something, badly when i sled pulled last.. @White wondee what year and what tranny/tcase do you have? PTO port on the side of the tcase is an NP241DHD. I dont know what differences for rebuild parts it takes but i have found some. I think its in regards to the planetary, thats where a PTO would engage if you had one. Torque King/Quad 4x4 is good stuff but their prices are high.

-

Truck shakes at 55-65mph, Grinding/vibration when coming to stop as well.

@YeaImDylan, it would be easier to swap on a wastegated 12 cm^2 housing.. It starts getting complicated when you start swapping around turbines and housings, Because you need a new housing with a new turbine wheel. My thread on turbo options has some more info on the turbo you have. @dieselautopower, is the 12cm^2 housing available separately for a 73.4 turbine?