Everything posted by ISX

-

Melt down maybe?

Well 1500 will definitely do it. If it's a continuous knock I would definitely tear it apart and see what happened. Post some pics of your findings

-

Melt down maybe?

What all do you have for gauges or chips or stuff like that? What was all their max readings if you do have some?

-

Voltage out of Fuel Pump Relay

The electronic control module (ECM) enables the lift pump by sending a signal directly to the lift pump. The ECM fast-duty cycles the lift pump on and off during cranking, and it enables the pump once the engine has started.Lift pump is turned on for approximately 5 seconds when the keyswitch is first turned on. With the hood raised, it is possible to hear the lift pump running when the keyswitch is turned on.The schematic of it shows constant 12VDC supply. It is not variable, but the ECM can turn it on and off. Pressure drop can be a number of things from the VP44 using it and the pump not being able to keep up, having a weak overflow valve, or having a clogged fuel filter. This is assuming your fuel pressure sender is post fuel filter.

-

Overhead Console

The dash either looks exactly the same or not I haven't traced my wire to see where exactly it goes. I didn't think there was that much to it. I take it the truck didn't have the temp probe in it? Might be hard to track one down at junkyards, maybe not though. Stealership probably wants $50 for it. I don't know where Mike got this, nor does he seems like lol, is there a brand or anything on that at all Mike?

-

Overhead Console

Depends, dobienut. If it is a 98 truck, then you got all the MPG stuff and all that and have the issues like mike is talking about. If it is a 97, it has temp and direction and thats it. If the dash is the same as yours, it's a 98 with all the MPG stuff.

-

Overhead Console

Take the headliner from that truck too

-

Overhead Console

As far as I can tell, they are interchangeable. The temp sensor is on the beam to the left of the drivers side headlight. You can see the white connector. The sensor is just a a black stub, looks like the top of a spark plug kinda, only black. http://forum.mopar1973man.com/attachment.php?attachmentid=1085

-

Clutch not disengaging..

Yeah, the south bend bearing and the new one were both sealed ball bearings. I did see the crappy needles in the stock flywheel the other day. They are not bad, they just run out of grease so fast that they end up rusted and disintegrated. There are a lot more needle bearings than ball bearings in one of them and since they are needles, they have much more surface area. This equates to a very strong bearing, but, if they run out of grease, then you have problems. U-joints are the same way, stockers do not have any grease certs in them, so unless you take the driveshaft off and pack grease in there, they will do the same thing, as mine did last summer.

-

Damper

Stick 2 bolts into 2 of the 4 damper bolt holes opposing each other, so if you were to number them, put the bolts in holes 1 and 3, then put a breaker bar or something in between them to bar the engine over. Obviously you will have to leave the bolts out a little bit. You might try and find 2 longer bolts with the same thread so if you bend the bolts doing this, it won't matter. It won't always bend them, but it can, and if you used the damper bolts, now you have 2 bent ones.. You can also get a flywheel barring tool that goes into a little hole on the bell housing and uses the flywheel teeth to bar the engine, this is the preferred way but you have to buy the tool to do it.

-

A Shopping trip to Boise, ID

Geeeeez! Well go for 2 months then I am gonna have to save that pic so I have something to compare to if I ever get my own house. Right now I could only go a week at a time eating the same thing all the time. You guys really got it made

-

engine coolant flush

If I drive long enough it goes to 180-190, bouncing off the two.

-

Boost leak!

Alright I did some physics searching. Mike is 100% right. So you take your compression ratio to the 1.3th power, then multiply that by the total amount of pressure (boost + 14.7).Whats interesting is monatomic gases have a constant of around 1.6, like helium. So if you somehow had a helium engine with the same 17 compression ratio and 0 boost it would be at 1367.8psi, or 1030 if you make it 1.5 for heat reasons.

-

Boost leak!

Whats the 1.3 for? You doing something for altitude? As far as I can tell, you just take 14.7 and multiply by compression ratio and thats your no boost cylinder psi. Add boost to 14.7 and multiply by ratio for your boosted cylinder psi. :shrug:Hmm, or is 1.3 the constant for air compression.

-

A Shopping trip to Boise, ID

Nearest traffic light is half an hour away lol. Don't ask me how this little town got a college on it. From where I am there is a gas station a mile west, or if you turn right out of my apartments, the next gas station is maybe 30 miles away. Half the town is probably just college kids. Population is 1354. I do have a NAPA within rock throwing distance, so I got one up on you Need to get some fish in that pond! I can have bonfires anytime here too lol. My poor truck hahahaha, yes it looks like its suffering on that marble floor I think if I were you, I would stock up on food for a month and spend all my timing going up that mountain I saw across the street and to the left? of your house. Every time I drive into town, I feel like I am wasteing time that I could have spent doing something like going up that mountain lol. Maybe I will do a drive through video of this town, after I clean my windshield

-

A Shopping trip to Boise, ID

I will make a vid tomorrow of my daily trip. You guys will laugh so hard, basically the reason I like watching these vids so much. You will see what I mean tomorrow ---------- Post added 05-25-2010 at 12:19 PM ---------- Previous post was 05-24-2010 at 08:17 PM ---------- Alright here you guys go. The weird loud noise is my sunglasses sliding across the dash with every turn I make, put armor all on too think yesterday So now it should be obvious, so make more vids mike! lol http-~~-//www.youtube.com/watch?v=A3ui1DCGm2E

-

Clutch not disengaging..

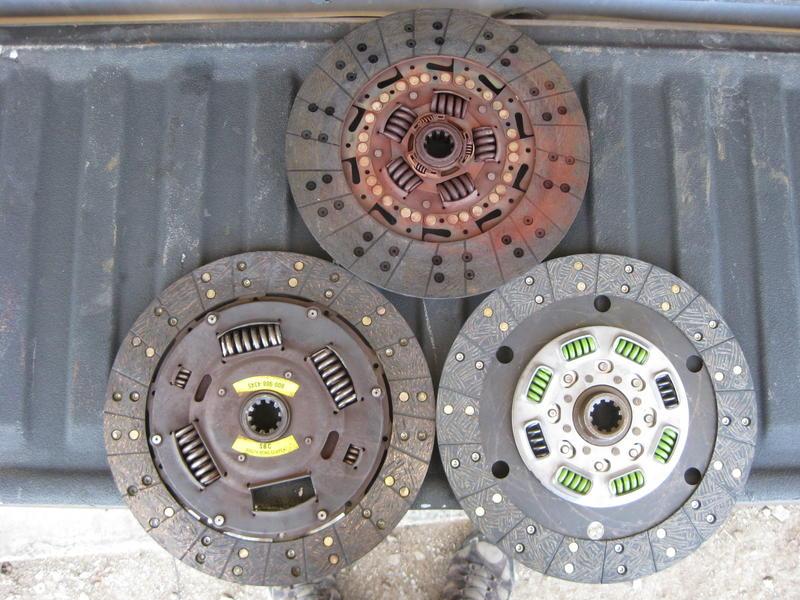

I noticed that too. Thinking maybe the stock clutch had a weak pressure plate so they made up for it with surface area. I wonder if the aftermarket clutches have to use a smaller surface area to keep the clutch from grabbing too good.. I mean if it can grip twice as much torque with less material touching, I am thinking if it had the same amount as stock, it would grab unnecessarily hard. Not sure though.

-

A Shopping trip to Boise, ID

I've just been watching it over and over when I get bored to simulate me driving down the road and not having to waste fuel. I did test the limits yesterday when I went back to college on 1/8 tank. If I was going downhill or slowing down, it was going under the red on the gauge. I did 55 the whole way and the last part I was getting a little worried, so I bent the drivers side mirror in to gain anything 0.00001mpg lmao. Keep adding vids! The only thing I was going to tell you was how lucky you were to be able to drive on all those roads

-

Dropping the 47re (a618)

Thats the only pics I could find with 10 min of searching. Someone on here with the 47RE would have to take a pic to get anything better. Maybe you got it figured out by now

-

Dropping the 47re (a618)

http://dodgeram.info/tsb/1994/21-24-94.htm That help any? I'll keep digging. Only other thing I can find is the second pic in post #4, still not very good but not sure what exactly you need help with. http://www.cumminsforum.com/forum/94-98-powertrain/254445-tv-cable.html

-

UH Huh, like this will ever be possible?

So how about you take advantage of the heat to create steam. Have like a little half piston in between each regular piston that has a lot of the heat localized to it, inject water into it and it will create steam instantly. Have it set up so it pushes each piston to TDC on the compression stroke. So it would be like a 2 cylinder engine with the 2 pistons 180 degrees out of phase from each other on the crank so that when the steam piston pushes down, it pushes the diesel piston up on it's compression stroke. So that takes care of some of the lost heat, takes care of all the power lost during compression stroke. I think it would have to be a slow diesel, like those Lister diesels that have huge strokes. When the steam exits, have it drive a turbo using a special turbine. Got you all thinking now don't I! Just another crazy idea that won't work that I came up with in the last 5 min :lol:I guess if you had it super perfect, the water injected would take enough heat away to almost remove the need for the radiator. You would have to get really perfect with everything. Get every degree of heat to that steam part. Actually the exhaust is really hot so theres plenty of heat, use the exhaust and the heat from the rest of the engine. Hmmm

-

Dropping the 47re (a618)

Well I had to give you a hard time somewhere along this transmission expedition lol. I actually haven't driven mine in 2 weeks now. But I don't think I coulda done what you did any faster, probably twice as long knowing me. I mean it took me 12 hours just to put mine back in, and all I have is 3 things on the trans to hook up, a crossmember and driveshaft If I had some big tires for the creeper, I could probably have ran over all the tools a little smoother.

-

Clutch not disengaging..

I got the second one down (NMU70279-01) on here. Stock hydraulics, well new stock hydraulics now I will go look at the box today sometime, south bend has so many on their site I am not sure which one it is. I know it's Con O but that doesn't seem to be specific enough. I have maybe 4 more tapes than that Had to keep changing because the camera glared on the newer ones. The south bend one is the only broke one, the stock one is fine, I have the pressure plate and flywheel for the stock one still, stashed away. It just wouldn't hold the power at all. The turbo would light and so would the clutch ---------- Post added at 11:56 PM ---------- Previous post was at 11:52 AM ---------- Finallllllly got it back together. I wasn't going to stop til it got done tonight, almost midnight but, I wanted to see it move Everything is perfect, shifts nice, everything. Little bit different clutch feel, gonna have to break it on for a while and see how it changes. Took me about 12 hours to put it all back together Think Mike does it in 1/4 the time, maybe less lol. I take my time and make sure everything is perfect 10 times. Took me 40 min to fill the trans from the top, now sure how to get it so it flows down faster than 1 quart every 10 min. One thing though, I drained all the oil from it from the drivers side, lowest bolt on the PTO, and it drained like an oil pan when I took that one bolt out. I always did it from the passenger side and coulda sworn I had to take all the PTO bolts loose and break the cover loose to get it to drain, and I talked with Guesswho512 who said the same thing when he did it on his passenger side. So next time you guys drain, try the drivers side

-

Manual trans swap.

As far as which one will hold more before you need to do the things like GuessWho512 said, it's a tossup. They will both hold about the same amount before you start messing stuff up in them. It really just comes down to whether or not you want to shift the extra gear. Now as Mike said, parts are hard to find and therefore expensive on the NV5600, so if you do plan on turning it into something with 500+HP and all that kind of thing, you will have to fight for parts with it. If you treat it right and don't plan on modding it to high heaven, you shouldn't be breaking parts on either trans and they will both last a very long time.

-

new injpump, head'n out on a long trip

What upgrades are you curious about? You seem to be pulling some decent numbers for mileage already. The exhaust and air filter do let it breath easier which you may have noticed. One thing though, ditch the K&N and get a BHAF, K&N's have terrible filtration characteristics. http://forum.mopar1973man.com/showthread.php/18-BHAF-filters... Your posts can be as long as you want, the more info you give, the more help we can provide

-

Clutch not disengaging..

I have the box for the SBC and everything, I put it in. The stock one wouldn't hold it at all.Alright heres some proof.The stock clutch is 12 1/4", the other two are 13" upgrades.