Everything posted by wil440

-

Need a sanity check.. changing careers

Diesel here is now £1.60 a litre or £7.25 per UK gallon, our gallon is 4.55 litres whereas your gallon is 3.78 litres Yesterday and today I've used £135 of diesel, I charge £1.00 per mile travel but yesterday was a right pigs ear of a day, I got a call midweek to fit a battery to a Bobcat skidsteer, the site is 50 miles away from me so because I couldn't get to see the battery decided to get a genuine Bobcat battery on the machine serial number, bound to fit. Gets to site yesterday, pulls the brand new bobcat battery out of it's box, fits it and tries to start it and nothing..... voltmeter..... nothing.... zero volts, pulls it back off and it isn't the easiest battery in the world to get to, voltmeter again zero, pulls the lids off and NO ACID at all bone dry battery, box says in big letters "warning hazardous liquid do not tip" and all the rest of the warnings you'd expect, Calls the Bobcat dealer and it turns out after some digging someone somewhere did not put acid in this battery, this was shipped from wherever it was manufactured in a sealed box and should have been shipped wet so yesterday I couldn't bill for, I had to find a generic battery last night to fit this morning, Bobcat rubbish will be going back Monday for a credit, but on the travel and 1 hour labour yesterday I'm out £150 at least. Having next week off which is the first time I've had any time off in 2 1/2years, I don't work on site every day but I am sort of on call 7 days a week to the company that I do repairs for I was 60 last Tuesday and my wife surprised me with a trip to Finland to stay in a log cabin in the wilderness to see the northern lights, leave early Tuesday morning Russian invasion of Ukraine will certainly increase all fuel prices and it will have an impact on the cost of living but that's nothing compared to what Ukraine is living through

-

Need a sanity check.. changing careers

Sorry I got to this late I had a grandad in the 60's that had lost fingers in a rail mill years earlier but he fixed and saved stuff, me from the time I can ever remember I sucked it all up like a sponge, he died in 72 when I was 10, my uncle sort of took over and I remember him driving 30's and 40's cars and fixing them Fast forward to 1978 and I'm leaving school at 16 I had a lot of interviews for apprenticeships, Nation Coal Board was one ... mining underground, A crusher manufacturer was another..... Terex Pegson I chose a HGV truck apprenticeship and then did light vehicle and heavy mobile plant, I have done heavy mobile plant for over 40 years, I turned 60 last tuesday and would not change a thing, you fix a Cat 777 everything else is easy Point of this is YOU know when you find the right, I have hated the 5.00am starts, I have hated the pressure when I worked for Finning the Cat dealer here, I have hated working nights etc etc etc but never hated what I actually do Once you find it you'll know

-

Brakes - Check your hardware too

Mine is drum rear so different but I adjust the shoes first, I do prefer to remove the drums to check everything first and also to check there is no lip on the very inner edge of the drum, if there is I grind it off so the shoes can be adjusted very close to where they need to be before messing about through the backplate, also once the lip is gone it's possible to slide drum on and off to get the shoes settled in the right place. Once the shoes are adjusted if the park brake pedal is still going to far I adjust the cables/splitter/equalizer

-

Brakes - Check your hardware too

I have to check my rear drums as the parking brake definitely need adjusting and it's time I had a look in the drums, I have shoes Fronts need looking at too as pulls slightly to the right, these are no problem as I've got spare calipers, pistons, seal kits, sliders and bushes, and maybe 90 sets of pads and no that figure is not an exaggeration The Jackal 2 used by British forces uses Ferrari Tractor axles and brake discs with 3. 2nd gen Dodge Ram calipers per wheel, I used to supply the Company that built them with brakes got a few left over

-

1998.5 47re auto hard OD shift

Ahh that's something I didn't know, so highly possible it's just a calc that puts the LU light on in 3rd

-

Injector Brand Choice

I plugged in this morning I took pictures of my Modis screen but when uploaded to here they are upside down, right side up on my phone ?? There is the factory options for tyre and and axle BUT there is also a custom tyre count option, just guessing but would this be revolutions per mile ? Mine is set for the biggest tyre on a 16" rim and the tyre count is 400 as the pic shows this cannot be right, I haven't used the custom tyre count as yet, tyre calc online say my revolutions per mile are 615, so I'm going to set it at 615 and see what happens. There does not appear to be an option to set the axle ratio but if the tyre count is changeable I guess you could get to the correct overall for the speedo

-

Injector Brand Choice

I can't remember what the biggest tyre was but you are probably right about 33" I also can't remember how many axle ratio's there are or whether that can be just inputted as any figure or just the factory ratio's If this 4th storm in a week here calms down I'll go plug my Modis in and see what I can see, the only thing is my truck is 98.5 so might be different who knows at least you might know then if it is worth giving away beer or not

-

1998.5 47re auto hard OD shift

That's what I thought as I've never felt it happen but I moved my quad screen a little closer to me so I could pay a bit more attention to the little LU light and it does light when in 3rd with OD on, It was very brief and I'm not saying that the convertor actually locked as it was so quick and I never felt a thing and it then went straight into OD and then LU once revs were right

-

Sway Bar Diameter ??

One the left side, the side that's up against the frame, is that a gap I can see, they should have some crush and I would expect to see a gap, maybe an 1/8th or so bracket to frame with the bolts just hand tight or just up to the bracket then as they are tightened there is the crush, if there is no crush then the bar will move in the bracket yes it has to turn in the bracket a little but that's it and if they were rubber bushes they would be somewhat squashed If you installed the bracket and it sat right close to the frame before tightening they are too loose, and with those nylon or whatever material they are bushes they sometimes cause an annoying squeak when first fitted as they are tight, WD40 usually sorts this out then they wear/bed in after a while Put a good lever in between the bolt head and the bar top right of your picture, if there is any movement they are too loose and as tractorman says a shim between the bush and the frame will tighten it up nice

-

1998.5 47re auto hard OD shift

I actually witnessed 3rd LO today, only noticed for a very short period of time on the quad screen, never seen it before and didn't feel a thing, with OD on my truck spends no time in 3rd LU, I doubt it was actually in 3rd LU as it was so fast I don't think the trans could have executed the change, I think the PCM commanded 3rdLU for a split second but then decided on OD

-

Injector Brand Choice

My truck has 315's not quite as tall as a 35 IIRC, auto, I tow most of the time and when not towing I'm in a 30mph limit for the most part, I turn off the OD so 3rd lockup and use this a lot I like the look of my truck it's just right with the ally wheels and 315's not too big as needing a lift but enough, I do tow into some boggy places so prefer some thread 3rd OD and my final ratio to the ground really suits our speed limits here in the UK as it will go right down to just below 30mph without dropping out of LU and at 60 I'm at 2100 to 2200rpm with OD still in reserve for downhill, when not towing I don't really care and neither does my truck it just does what it says on the tin ( I only use 3rdLU in a 30 limit) If I drive my truck like the above EGT's are low and I'm not too bad on MPG (did a test 2 days ago but due to this storm we've had haven't had a chance to refill to calc MPG) If I leave my truck to decide the gear it needs as in leave the OD on then I can see EGT between 900 to 1100 towing this is not all the time this is just either on grades or passing or just putting a Jap pickup in it's place which I do quite a lot There are more ways to skin a cat and while @Mopar1973Man is right I get the same end result, I just use OD as OD Not quite the same as a manual though but I guess 5th instead of 6th is about the same Yes a Snap On Modis ( not sure if it's called that for you) can change axle ratio and tyre size, I did the very same for a friend of mine that had a ABS light come on on 3rd Gen 1500 hemi that had a PCM meltdown, He fitted a same year same truck PCM but tyre and axle ratio was wrong, soon as I connected and looked at stored against tyre sizes and axle ratios job done..... was dreading an actual ABS fault TBH.

-

Something to mess around with

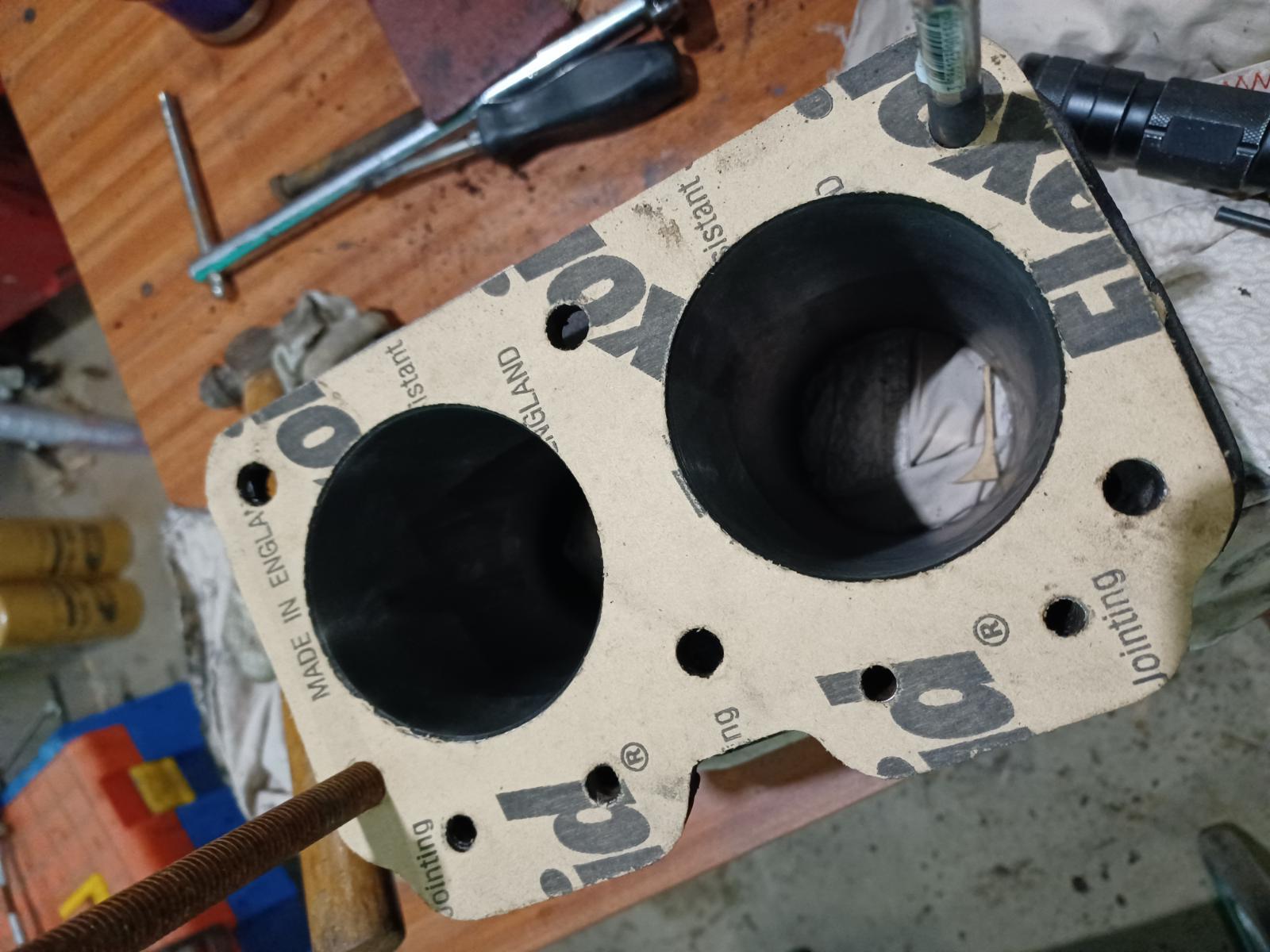

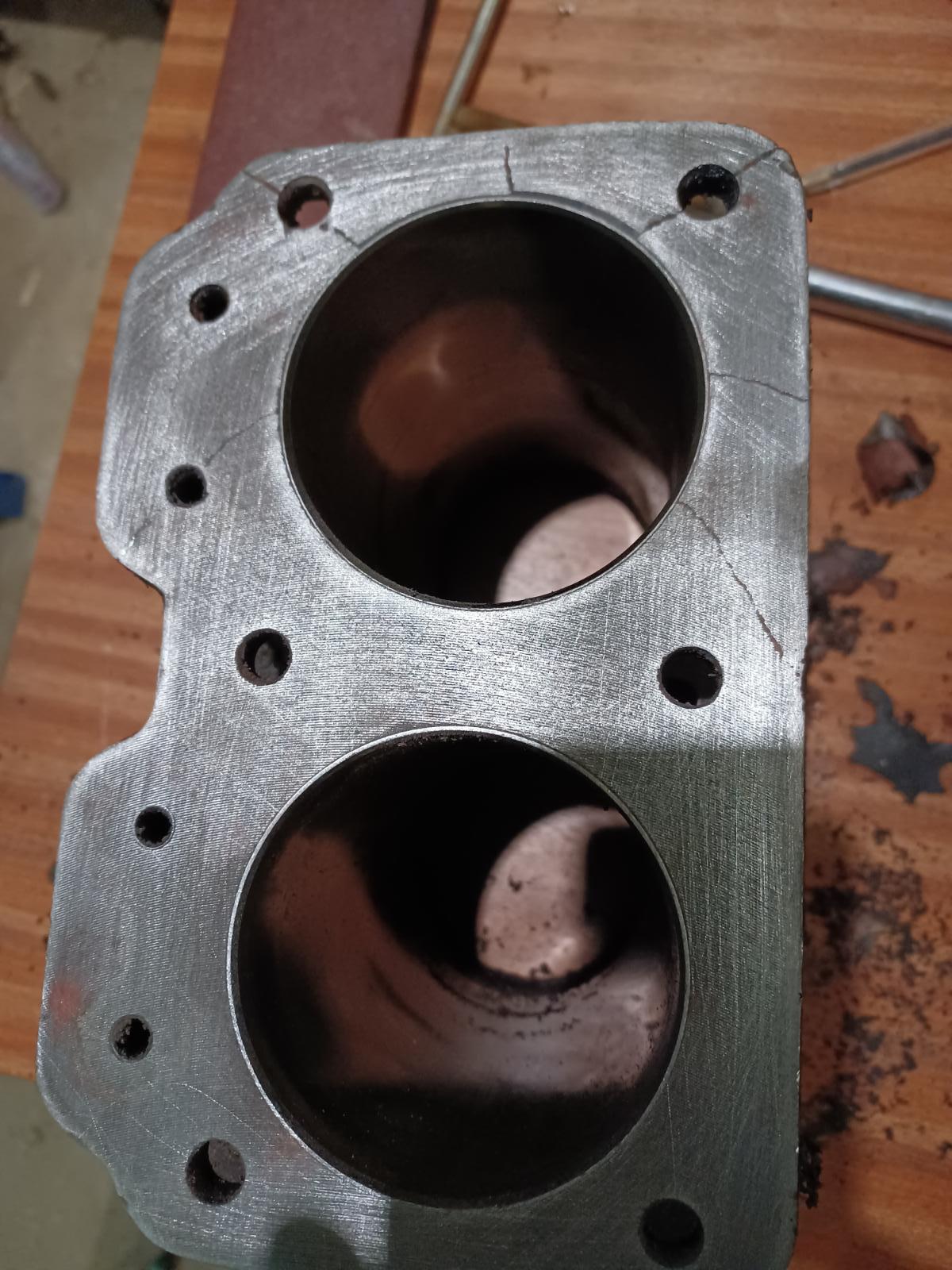

I learnt something today, while looking at the original manuals for this rotavator I was looking at the parts part and there were 2 different barrels, one for petrol/VO (vaporizing oil) and one specifically for "Lamp Oil" does say anything about what the differences are/were, if it was bought as just petrol there was just a thin gasket under the barrel, if VO there were 2 thin gaskets either side of a spacer shim to raise the barrel and lower compression. Here VO, TVO and lamp Oil were alternatives after the war as the gov increased taxes on petrol but not on VO/TVO/LO TVO here was very similar to Kerosene I know a guy that has a WW2 Cat D8 that was at Omaha beach head, he's restored it and takes it back every year for the anniversary to the very same place it landed, he's a self employed welder and has a low loader truck this also has the pony motor and he's told me it's a ~~~~~ to start Also when I worked for Caterpillar at Desford they has one outside the offices, they "restored " it but on closer inspection they just painted it, it didn't run..... cheapskates Got the barrel cleaned/honed and a base gasket made, note the gasket paper is MIE Got the valves out of the head, cleaned, lapped them in, refitted and got the barrel and head refitted Tomorrow.. adjust the valves clean and inspect the carb then see if I can get a tune out of it

-

what controls the "wait to start light"

Search in articles here is the link to the WT mod Engine ECM, on the drivers side of the block,, the one on the passenger side firewall is the Powertrain Control Module or PCM so not this one New ECU not available, repair what you have if possible, ASC will sort you out, never had to use them YET but that's where mine would go if it failed and I'm in the UK, company of choice for the guys on here for ecu/pcm etc

-

Something to mess around with

Not done too much today though as the UK has just had a once in 30 year storm, 80mph winds where we are, record broken at the Needles on the Isle of Wight at 122mph, not wind like you guys get as we don't get Hurricanes, just a winter storm but a bad one at that This was the whole of the UK from tip to tip and left to right, no route into South Wales as the 2 road bridges over the river Severn closed trains not running and some planes having to divert to the EU to land

-

Something to mess around with

Me too, when I started work in 78 there were quite a few older guys in the workshop at least 2 were over retiring age which was 65 then so these guys would have been born around the time the Titanic sunk and starting work around 1930, these guys would have been easily working on stuff from the late 1800's. I have known guys who worked on steam Rustons which were rope excavators but were steam driven, one guy I worked with operated a diesel rope excavator when I knew him but he worked steam way before, same guy same quarry he started as a pony man, ponies were used to haul tubs of granite out of the quarry which were hand loaded, quarry upgraded to a steam winder and the engine was still there when I started, he then changed jobs (same quarry) and became a "getter" he would drill a hole at the top of the face with a steam and later air drill and get the drill steel down a ways then tie a rope to it and over he would go with a long bar "getting " all the loose granite down, this had to be done before the next set of holes were drilled and blasted, all year, 6 or 7 days a week I have the shareholders meeting minutes from this quarry dated 1898, it's just up the road from where I live, I worked there from 1978 until it shut in 1994 or 95, still carried on working for the same Co just at a different site, I left in 2004 and now they have reopened the quarry where I started work. I used to go to another quarry (same Co) Groby Quarry maybe 8 miles away, that site had a long wooden shed close to the weighbridge, inside was a steam compressor and compressed air was piped everywhere on site, when I started it was powered by an electric motor but the steam engine was still in it's original place, after that site shut it was removed to a local museum and restored Bit of History GR - Groby & Charnwood Granite Co Ltd, Groby Granite Quarries, Leicestershire Opened in 1832 just to the north of the village, the first quarry at Groby was connected to the Leicester & Swannington Railway by a standard gauge line which, like the L&S, was built without Parliamentary authority. The junction at Glenfield was via a turntable into a loop siding, but in 1865 the Groby Granite Company took control and laid a conventional junction. The present quarries some distance beyond the village are a more recent development, and the line latterly was some two miles long. The original engine shed and wharf were opposite the old quarry, but a shed was later built at the newer quarries. At least ten steam locomotives (mostly Hunslet 0−4−0 saddle tanks) have worked on the line over the years, and these include a Robert Stephenson 0−4−0 tender loco dating from 1833 and an 0−4−0 vertical boiler tank locomotive which was known locally as the "Groby Coffee Pot". The two steam locos which survived until recent years and the diesel which replaced them are included in the locomotive list. In 1966 all rail traffic from Groby ceased when British Railways closed their branch from Desford to Leicester West Bridge, and all production now goes by road. There was also a 2ft 0in gauge system in the quarries which was of considerable length. The original locomotives were a pair of Hunslet 0−4−0 saddle tanks named JUNIOR (596 of 1893) and SEXTUS (652 of 1896). These were replaced by three Hunslet 0−6−0 saddle tanks named NONUS (992 of 1909), SEXTUS (1021 of 1910) and JUNIOR (1417 of 1921) which were scrapped after the system was abandoned in 1943 in favour of road transport. Pic is Groby Quarry, from 1962 Fowler Loco, the tipping ramp where the truck is tipping into the wagons was still there in 78 You could go into the quarry, find the stonemason and tell him what you wanted, granite kerbstone, granite cobbles for streets, dry built fireplaces, take it away and add cement and job done 1/2 way out of the quarry was a pumpmans hut, 10ft square hole 8 ft deep cut into the granite with a steam pump, one guys job to look after it, same right at the bottom There were carpenters shops, welding shops, fitters shops etc not been used for over 20 years but just looked like everyone was on a holiday other than the dust Well thank you I may have a bigger problem than the stuck valve, pulled the barrel off today and the baseplate is cracked, it has been repaired before and doesn't do much other than seal the crankcase to the barrel base, there is another gem close to me for sale so might just drop a offer on that, seller says it doesn't turn over, or just make a new gasket and try it Pictures of cracks Now this was not leaking and the baseplate is flat and none of the pieces are in anyway loose, probably going to make a base gasket and try it, HG is copper so with a Anneal that will be fine

-

Something to mess around with

Good to see people interested in old stuff, I have a lot of Whitworth spanners never used them in years, Foden trucks had a lot of whitworth, where I started work from school they had a fleet of these from the late 60's still got the tools as I never throw tools out. Checked the serial number on it and it's 1963, 1 year younger than me

-

Something to mess around with

BSW is British Standard Whitworth https://en.wikipedia.org/wiki/British_Standard_Whitworth wrench sizes are bolt diameter not AF and neither metric or AF is close to most Lamp oil engines were common here, the intake and exhaust on a Howard Gem that runs on lamp oil are sort of together, the petrol version has 2 gaps to isolate the heat from the exhaust, lamp oil engines were started on petrol then once warmish switched over to LO Tractors were often the same but the fuel was called I think TVO as in Tractor Vapourizing Oil, used here and in Australia it's made out of paraffin or Kerosene to you https://en.wikipedia.org/wiki/Tractor_vaporising_oil Also take a look at hot bulb engines it's a 24" tiller to a depth of 9", I used one of these rotavators before I left school at my part time job at a garden nursery nearly 50 years ago, It was used to rotavate tomato houses after cropping and a big area that was used to grow trees, these areas would be like concrete but it never struggled at all, it was the master of me that's certain

-

Something to mess around with

Bought a Howard Gem rotavator over the weekend and collected it yesterday, sat nicely in the bed of the truck with the tailgate down, It was put into a shed in the 60's and never touched since, got it under cover and on trestles, turns over ok but one exhaust valve is sticking down a little, this one must have been open when it was parked Got the cyl head off last night going to pull the barrel and check the rings today Scored a set of tyres off of ebay that arrived yesterday Engine is a 810cc Jap 4 stroke petrol, doesn't look to be the VO engine which runs on lamp oil which I'm presuming is paraffin, all nuts/bolts are BSW sizes (time to dig all my BSW wrenches out)

-

Anyone use solder seal wire connectors?

Get a box of Deutsch connectors, the DT range, fully reusable except the terminals, they are waterproof and easily used, just a 90 deg small pick to pull one wedge out, small seal pick works great but I have the original Cat brass handled pick that was supplied maybe 30 odd years ago by Cat Genuine Deutsch crimps are expensive here, not sure about USA but I have a pattern set which work great Boxed kits range from silly money right down to $20.00 or so, comes in 2 pin, 3 pin, 4 pin, 6 pin, 8 pin and more Most kits come with steel connectors but for added corrosion resistance and better conductivity Cat do loose male and female terminals that are gold plated, last time I bought some (50 of each IIRC) they were £1 per terminal, expensive but boy do they last and in the harshest conditions imaginable and if they do corrode it's a few seconds to disassemble and renew the terminals. I do a lot of electrical work on heavy mining equipment and never use anything else, I have solder equipment but rarely use it and the times I go to machines with beacons/lights/ seatbelt warnings etc not working and there's a corroded crimp causing the problem https://www.amazon.co.uk/Connector-Waterproof-Electrical-22-16AWG-Motorcycle/dp/B082WWDJV6/ref=sr_1_11?adgrpid=1188572967731455&hvadid=74286010557315&hvbmt=be&hvdev=c&hvlocphy=162514&hvnetw=o&hvqmt=e&hvtargid=kwd-74285945616902%3Aloc-188&hydadcr=4619_1948898&keywords=deutsch+connectors&qid=1645176657&sr=8-11

-

Front bumper top pad

Finally got around to refitting the top pad, none of the plastic clips survived so just drilled it at every clip and bolted it on, the thing won't fall off again as the only bolts I had that wouldn't have needed massive body washers behinds the bumper were 10mm Cat bolts, the best thing about these nuts/bolts is they will come undone even after years

-

High Fuel Pressure AirDog150

It's the return from the pump that really increases my FP when restricted slowly with a brake pipe clamp, didn't check what the head return did when restricted as mine all factory and not easily compressible to restrict Mine draws from the basket and both returns go back to that, I have made a filler neck return but not got around to fitting it, my fuels temps are around 80f this time of year after say 40+ miles towing and might get to 100f in the summer, but as I've said before my LP moves a LOT of fuel and after testing return flow last summer I know my truck does not puddle hot fuel around the basket

-

High Fuel Pressure AirDog150

Not familiar with any electric LP as I have a mechanical pump. Has this pump got a dedicated return back to tank, my mechanical pump has, it uses the original fuel supply line and my return from the cylinder head is what was the original return line so I have 2 returns, only asking as when I was testing my mechanical pump, if I restricted the pump return from the regulator fuel pressure went way high and if I had carried on it would have got that high it would have bust my 30psi gauge bearing in mind with a mechanical LP the more rpm the more fuel. Correct me if I'm wrong but it was all fine until it was fitted to this new to you truck ?? Is it possible that "if" the pump has a dedicated return that it might be restricted somehow as in a soft line kinked or maybe a steel line kinked or if it uses the basket something is restricting the return there or it uses the small return at the rear of the cylinder head and it's just not big enough ?? If it has got a dedicated return line disconnect it and run it into a bucket then see what psi you have It could well be that the gauge is reading wrong but other than restricted return lines or smaller return lines from one truck to another I can't see how a relief spring actually grows from one truck to another to increase FP from one to the other, this is assuming I've understood that your fuel pressure has increased ?? And I can see around 22psi ish at anything over 2300rpm, doesn't bother me as I never go over 2300 anyway

-

1998.5 47re auto hard OD shift

My tow tune didn't really get much over 20psi boost where as the test tune builds over 30 psi, tow is higher timing figures, test is lower, I'm going to add timing to my test a little at a time and well just test Yes, I recently went back to stock to test differences, won't be doing that again, slow noisy and just not nice, In fact I remember posting on here when I first got the truck "before quad" that I preferred my 3500 gas truck as it was more refined

-

1998.5 47re auto hard OD shift

agree 100% as I said I'd read stuff and just got so bored with it all I just couldn't be bothered so left my towing tune as it was and never even clicked on edit fast forward to this week, little bit of time, watched the vid on here then built a tune from scratch looking at the tow tune I have and other peoples threads/tunes etc trying to understand what did what and why and how. I messed with it for a while whilst keeping within recommendations for timing and no studs and ran the tune yesterday for the first time but only local and without trailer Today trailer on and off to a Concrete plant only 16 miles away but motorway and on the way back I took a different route that has a couple of good grades I think 1. timing needs to be higher across the board, going to add 1degree and see 2. fuelling is low but this was one of the reasons for doing the tune anyway ..... diesel here is £1.50 per litre or higher but there is no haze or smoke at all so I will be going up on fuel a little at a time It runs ok, not as much power as my tow tune, EGT's are low and I saw maybe 900f on a steep grade in 3rd LU, this grade has a sharp corner right at the bottom so 25mph is about the limit at the bottom and it goes for around a mile ( I know it's not a grade like some in the USA but it is the steepest near me) Coolant temps are ok maybe 3f higher at 195 when pulling hard, not sure yet if this is an actual coolant temp increase or just because I was in it harder to test again, we'll see and test more

-

1998.5 47re auto hard OD shift

I took the truck for a quick test this morning, seems to run ok, boost way higher than what it is on my tow tune. 20ish on tow tune to over 30 max on this test tune, run not long enough to spend much time looking at EGT, coolant temps etc but egt may be higher, timing might be a little low Got to take my trailer to a job tomorrow so real test time