Everything posted by NIsaacs

-

Nv4500 fluid service

This should be fine. https://r.search.yahoo.com/_ylt=AwrgDmku8J5bh0sA6l1XNyoA;_ylu=X3oDMTByb2lvbXVuBGNvbG8DZ3ExBHBvcwMxBHZ0aWQDBHNlYwNzcg--/RV=2/RE=1537171631/RO=10/RU=https%3a%2f%2fwww.amazon.com%2fMopar-4874459-Synthetic-Transmission-MS-9070%2fdp%2fB009G9QHX0/RK=2/RS=hE9L4aXGUbwWXGBbR65cqb.9bwE-

-

Weird issue with brake pedal feel and PS pump

Installed the same filter in my '91 today, D-250 no hydro. I drained the pump out of the pressure line, turned the wheel lock to lock several times to purge the steering box and refiled, no flush. I started with a new quart of fluid and used 26 ounces, so it is a smaller system then the '01.

-

Power Steering Pump

Rock Auto shows several. When I used one of the numbers (351790) and crossed it to Napa it showed a NPS7200 but has a question mark for my '01, so....?

-

Oil Pressure and oil type

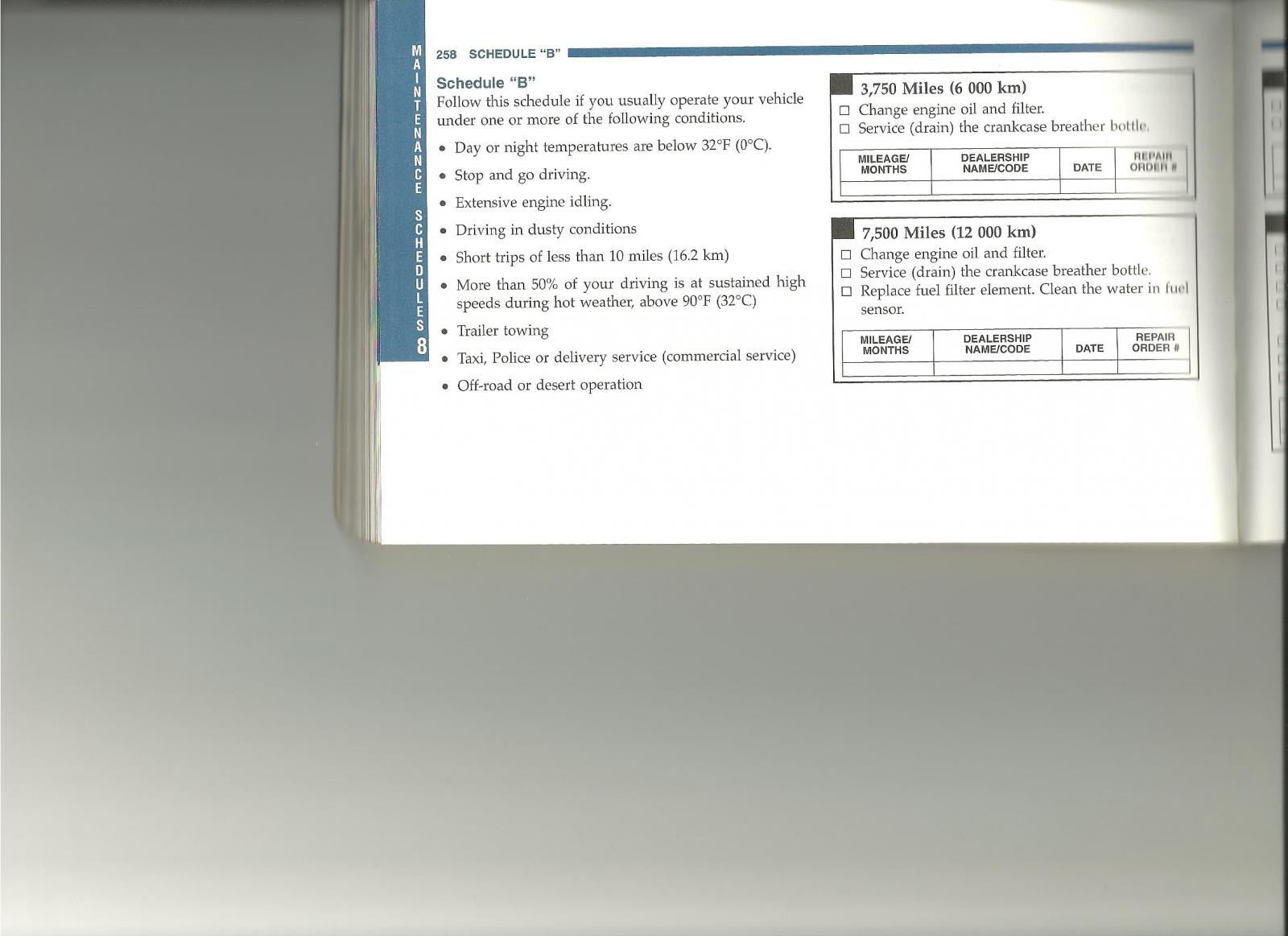

Just pointing out there is more schedules than one in the owners manual, that's all. As far as actual oil changes, that is a personal preference and can be all over the map. Some people swear by the manual, most don't.

-

Oil Pressure and oil type

-

Oil Pressure and oil type

Schedule "B" is 3750 miles. All my driving is B but I don't change it that often, about 5-7k.

-

Weird issue with brake pedal feel and PS pump

Yes, good advice, I will continue to change the fluid on schedule. The filter was $18.99 plus tax. They only had one in stock so I ordered another one for the '91. The Ford conversion already has one in the remote reservoir, it holds 3 quarts. I jacked it off one of my old IHC log trucks that was culled.

-

Weird issue with brake pedal feel and PS pump

Went ahead and installed a universal power steering fluid filter. Napa # PS351002, it also has a magnet and bypass valve for cold weather or if it plugs up.

-

Power Steering Pump

Maybe just change the seal?

-

12 volt jump cables about 25 feet worth.

2.0 cable is big and heavy. My brother built me a set out of 2.0, 18' long and they weigh 25#, they want to pull the clamp off the battery. They were nice for jumping heavy logging equipment tho. 2 gauge might be enough.

-

Light under hood

I carry several Craftsman battery powered tools including the light in my '01, my main rig, I use it even in the day time for dark areas. Seems like my normal flashlights always need batteries. My brother always has a small led light on his cap brim, uses it all the time.

-

Light under hood

I installed one of those (82 Ford) in my '74 Ford. It is getting sticky on the rewind but I am afraid to take it apart and clean it, I usually loose them dang big ole wound up springs, lol. I do have to unplug it because sometimes it stays on.

-

Waited a long time for this

Nice! Was the fitment good? I need one too, but doubt the oem is any better now than it was in '01.

-

Old article on 275rv injectors.. still ok?

I installed the RV's and Edge EZ in '03 with 34k miles on it, the year I bought the '01 and run that for 12 years. Then installed the Edge Juice 3 years ago with the same RV's, 320k now, still running good.

-

Exhaust system info

Sound is also dependent on single or dual. There is a big difference in sound with a single exhaust on a 1st and 2nd gen. v/s the 3rd and 4th gens. Mostly it is because of the center outlet exhaust manifold v/s the split manifold. My '74 F-350 5.9 Cummins with a center outlet exhaust manifold and duals sounds very similar to a split exhaust manifold of the 3-4 gens. Especially if you use a divided y-pipe, like this: https://www.youtube.com/watch?v=hy8NaAjxP34 Quick video of my Ford exhaust sound.

-

IAT and ECT connected?

I don't think you will see anything negative. 180 thermostats were the norm until emissions got in the way. At -30 the cab heat might suffer. I went to a 180 this summer for the first time and I am seeing cooler temps on everything associated with engine block/under hood temperature heat sink. Even my transmission. So far I am very comfortable with the change.

-

Weird issue with brake pedal feel and PS pump

Why? I live in AZ but it can get cold here. I don't expect any problems with outside temps. The pump makes heat almost immediately.

-

Weird issue with brake pedal feel and PS pump

Just hauled 3 loads of cinders, 20 mile round trip, 14 miles of slow county road pavement and 6 miles of slower dirt, ambient temps from 70-90, truck ECT was an average of 185. On my middle load with AC on, truck idling, the pump was 109, hydro 109, box 106, lines 105 and cooler 88. I tested the lines where the rubber meets the metal, about 6-8" from the hydro, I didn't test the lines at the box. This is with 285/75x16 tires, stock aluminum wheels. This size has been on the truck since I bought it, in '03 with 34k miles, it now has 320k. The front end is all original, other than the brakes and shocks.

-

Mph needle jumping like crazy

I didn't pay $500 for a used ABS Module, nor do I have to explain my foolish behavior about my used junk parts.....

-

Mph needle jumping like crazy

Used is not always junk, it has been 4 years now. I buy a lot of used parts, don't you?

-

Mph needle jumping like crazy

I agree, my '01 did the same thing when the under hood temps were hot. I bought a used one off E-bay and it fixed it.

-

Hello from AZ

Welcome Kenny, Nick from Snowflake, AZ

-

Rear Brake Cylinder upgrade

Nice video, thanks. I did this upgrade on my '01 several years ago, however, I went with 1/1/8" 1 ton 1st gen Dodge cylinders v/s the normal 1/3/16" GM's. OEM is 1", they work great.

-

Weird issue with brake pedal feel and PS pump

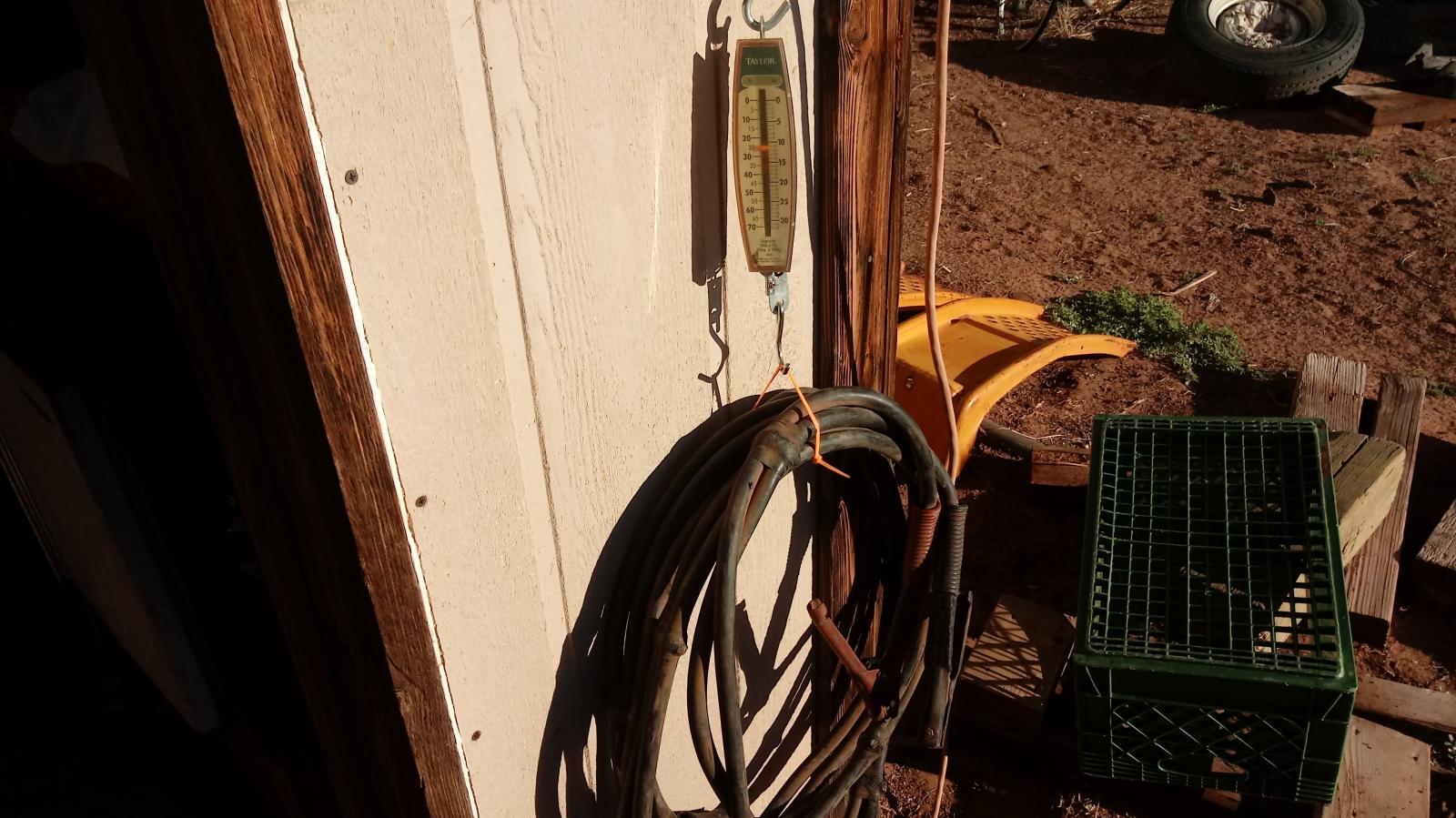

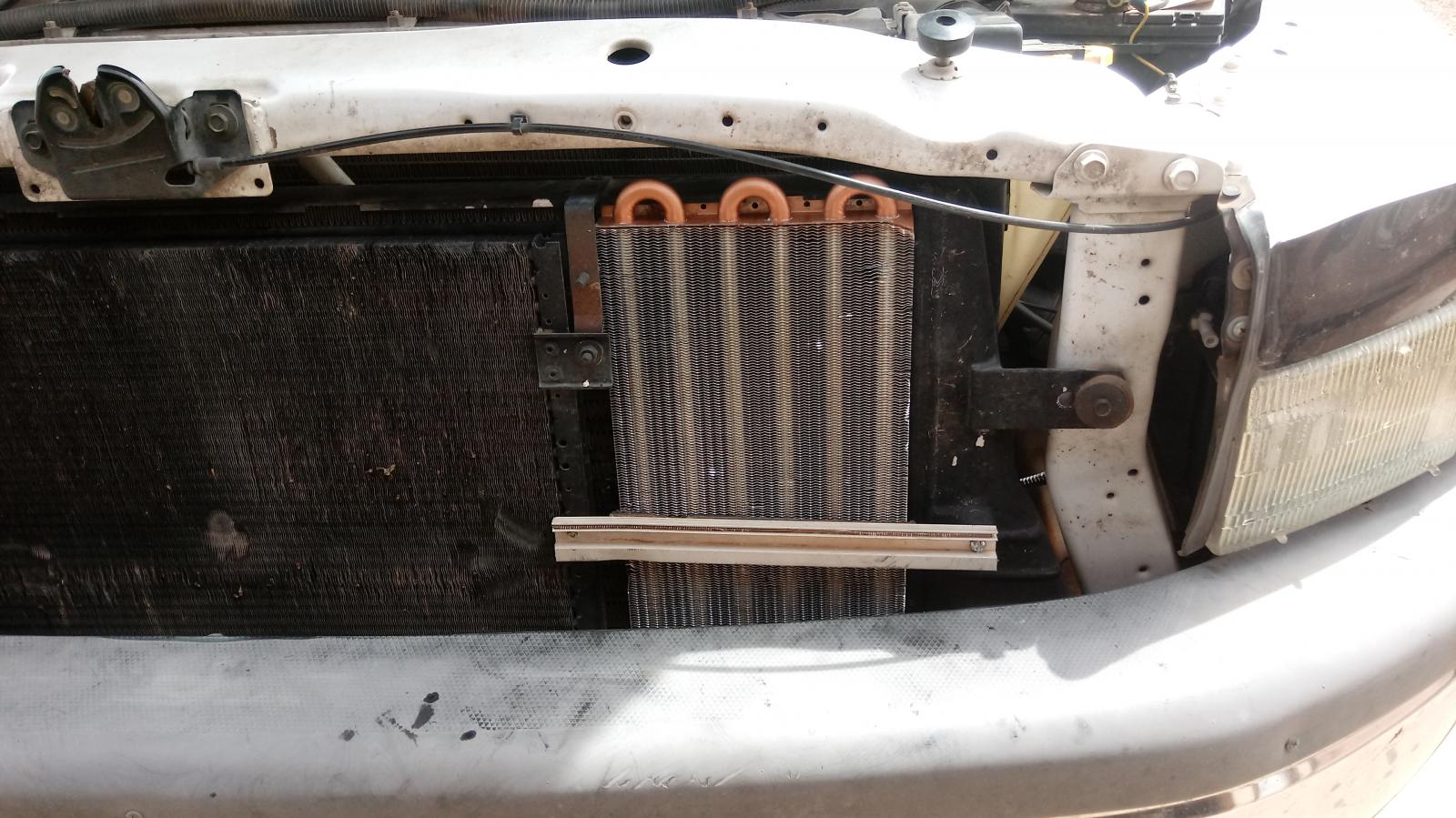

Thank you for the link, I saved it! Just did an install of a power steering cooler, it is a little large but I had it new on the shelf. I bought it for my old Ford (auto tranny) and then bought a new Dodge instead, (1991) so it has been on the shelf a long time. I also wanted to check return flow...on my truck, with the steering box return line pointed at my oil drain pan, I had my wife start the truck. The flow was massive and emptied the reservoir instantly. Granted, it only holds about a pint, but in about 2 seconds the fluid turned to foamy air. If I remember right, when I would change the fluid it only required a little less than a quart. The system now holds 1.250 quarts, a good thing. Here are a couple of pictures.

-

Weird issue with brake pedal feel and PS pump

Thanks for the excellent flow diagram...why couldn't I find it, I have been all over researching this conversation, lol I am still having a hard time wrapping my head around the above quotes. So there is no fluid flow from and to the pump when there is no input on the brake or steering? That the return line has no flow when the system is at rest so to speak? That the brake booster and gear box spools block all the flow until there is input? That the pressure line is pressured up at all times and the relief valve is reliving at all times so the pump can turn without locking up? On my old mid 70's Fords with a belt drive pump, any time the belt got too loose it would squeal/stop turning when you turned the wheel. Is that a little different system than our Dodges? Thanks again, Nick