Everything posted by Andyba20

-

She's dead. And I'm done with it.

This site is the premier 2nd Gen site for specific knowledge and content related to these trucks, so it’s important to have updated best practices, especially when we have evidence that changes long held help beliefs. I feel the same way about greasing the wheel bearings through the abs port. It shouldn’t even be a debate anymore…

-

She's dead. And I'm done with it.

Mike, I thought this was debunked by @Tractorman a while back. Meaning lift pump pressure has no say in when the overflow valve is open.

-

AC from AC?

Good info @Tractorman, hopefully I’ll get the new hardware installed while we still have a few hot days left here so I can compare before and after cycling. Kinda hoping my compressor clutch is bad so I don’t have to spend a bunch of time and effort chasing down whatever is causing the issues I’m having.

-

AC from AC?

So does that mean I’m within spec or no? 5 times per minute is 1 cycle every 12 seconds. Mine is cycling 3 times per minute or 1 time every 20 seconds. I’m going to get a new compressor and kit either way, but I don’t think I’ve been around another 2nd Gen that locks and never cycles. Guess they’re all showing their age.

-

AC from AC?

It cycles every 20 seconds or so which I thought was normal. I’ll do some testing.

-

AC from AC?

Guess I’ll just swap some parts and see what happens.

-

Power Steering Pump bad after flush?

Are you sure you don’t have an obstruction somewhere? What kind of fluid did you refill with? My pump went at 290K, I replaced with a brand new Napa unit.

-

Dodge 2500 OEM Hitch Receiver Failure

Different part number from yours it looks like…not sure if that means anything. My truck is a 00’ made in November of 99’

-

Dodge 2500 OEM Hitch Receiver Failure

- Dodge 2500 OEM Hitch Receiver Failure

I’ll take a pic of the oem unit later today, it was perfectly fine.- Dodge 2500 OEM Hitch Receiver Failure

I replaced my oem hitch with the same Curt class V you used. I had no reason to do it as I mainly tow heavy with my gooseneck. But, I got a good deal on the Curt and went for it. My gosh, a one hour job turned into a 9 hour fiasco. All of the tabs on the top of the bolts broke off when I was loosening them. I’d prepped all the bolts and nuts with penetrating oil for days. Ending up having to anchor the top bolts with a socket and breaker bar and then used a torch and 1” impact gun and just twist them all til they broke. The Curt unit is definitely heavier and seems well built.- AC from AC?

Last week I started getting some “pre-WT” mod like symptoms. Miss, cuts, tc lock/unlock at 30-40mph especially when lugging at low rpm. Truck has wt mod, nations 180 alternator, year old batteries, new battery cables, and lug terminals. Grounds are perfect. Everything is clean. Not a hiccup since WT mod 3 years ago. Trans is a year old with 5K. Around the same time this started happening I noticed my AC wasn’t blowing cold. Charged it. Then noticed intermittent cold ac. Everything in the dash is newer (heater treater, blend door actuator, evaporator, etc) Tested batteries and alternator for ac and get .01 to .015 with all accessories on or off, but did noticed a spike of up to .056 a few times when the ac compressor cycled. Could my ac clutch be going bad and causing these old symptoms to reappear?- America Today

Keep your circle small, prepare, and hang on tight. Also, for those of us who are Christian, we know we are imposters in this world, but we can’t live on the fringes of society. Stand up for the each other, and for the innocent these wolves will prey on.- Neg. cable location

There’s a stud underneath the drivers side battery tray, might be the one. You should be able to see it with a flashlight.- Quadzilla Injectors

Yes but that’s never justified a price difference in the past. Plus it doesn’t explain why DAP wouldn’t sell the Quadzilla brand on their website. They sell everything else under the Sun, why not injectors made in their own building?- Quadzilla Injectors

So why confuse your customers (DAP) with 3 different flavors of injector, and only sell 2 of them at dap.com? They have a 75hp injector set for $369 (which I assume are reman’d), they have another 75hp set for $546 (brand new), and then over on the Quadzilla site they have 75hp injectors for $699. Are DAP and Quadzilla not the same company in the same building?- Quadzilla Injectors

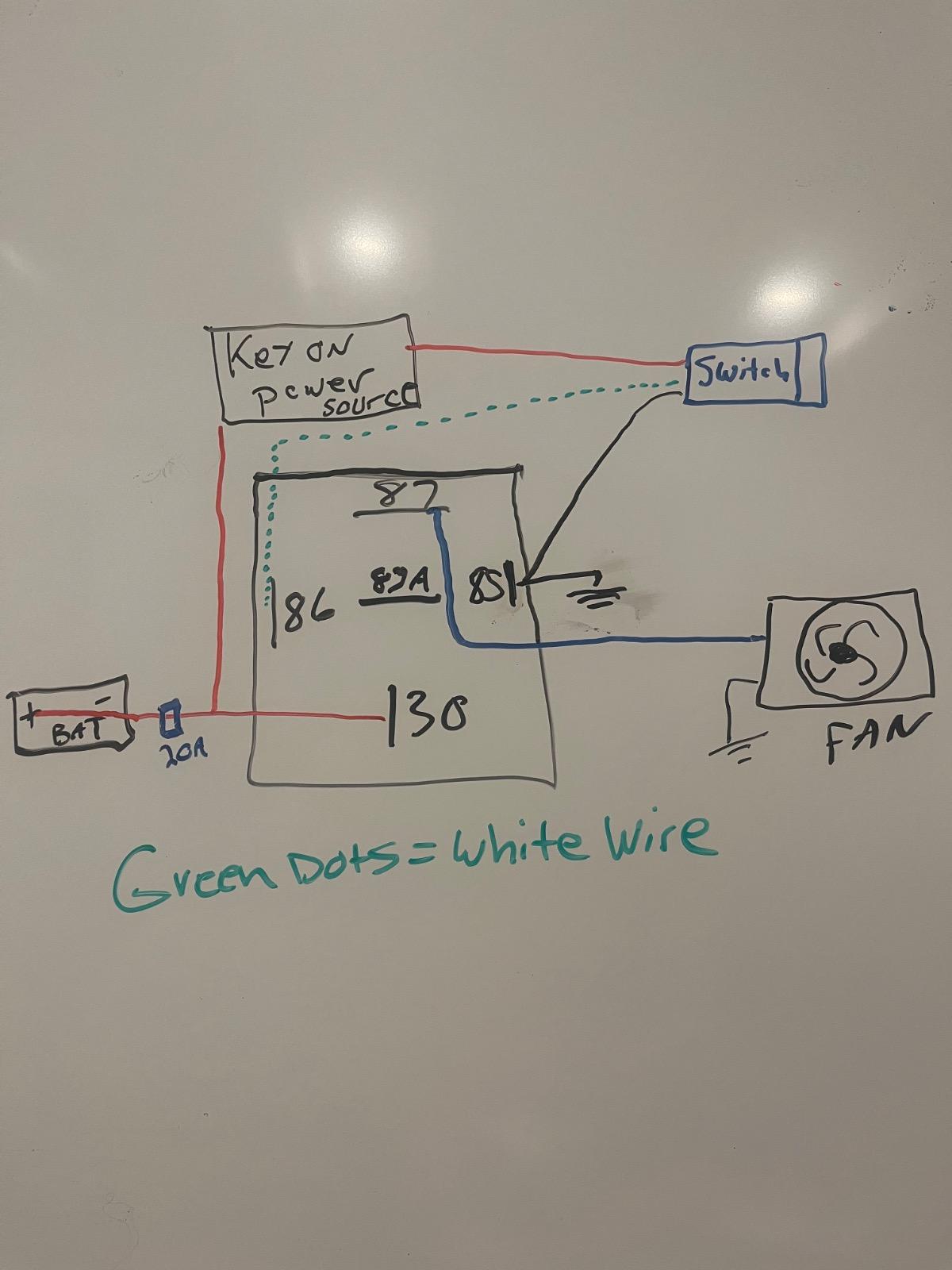

So back in April DAP sends an email launching the new Quadzilla injectors, but they don’t sell them on the DAP website. What’s the difference in the Quadzilla injectors vs the new DAP injectors they sell on the site? (Besides the green rubber seal)- Auxiliary Fan Switch

You’re always coming into these discussions with really helpful stuff @Great work! thanks a ton!- Auxiliary Fan Switch

- Auxiliary Fan Switch

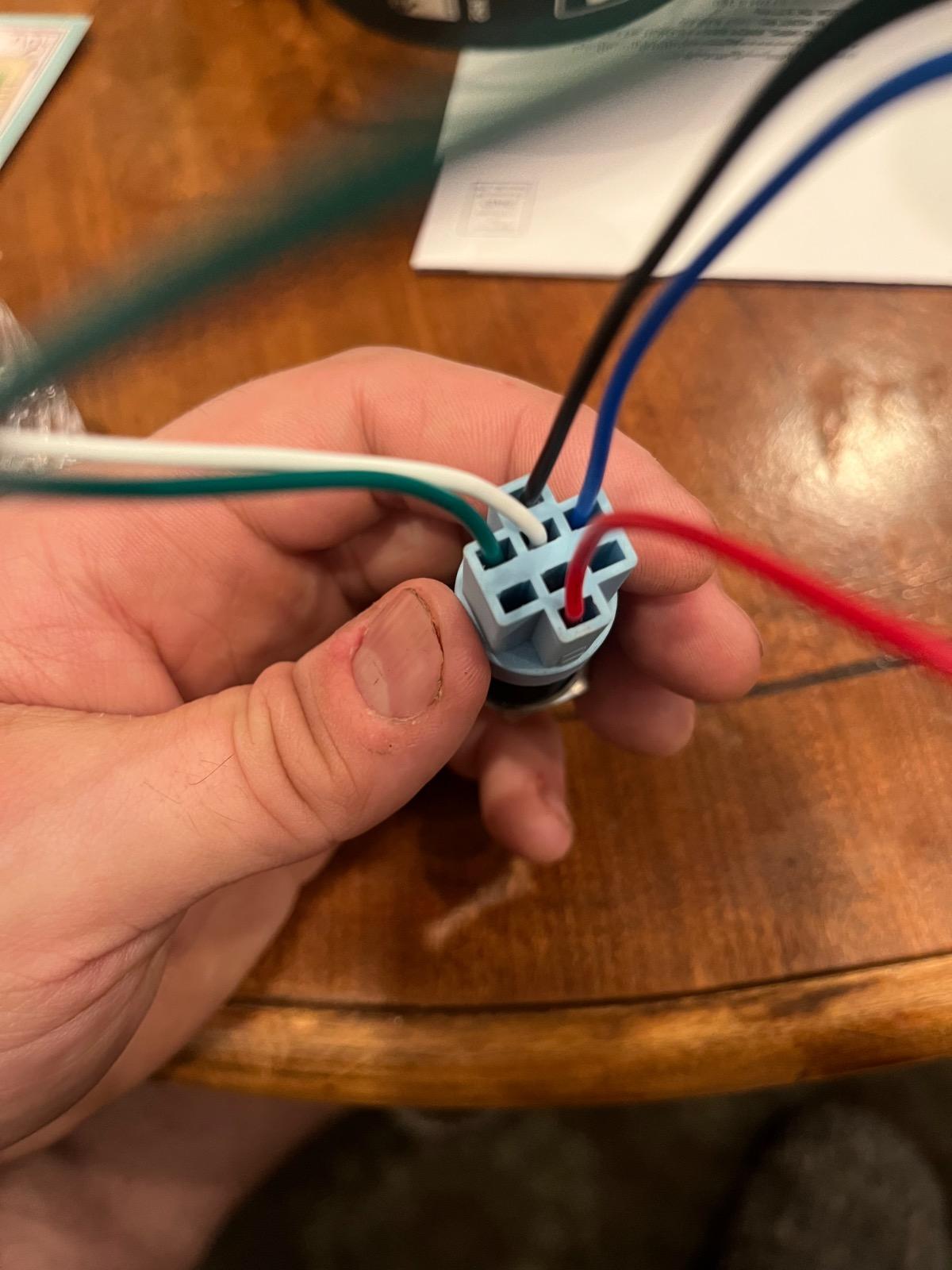

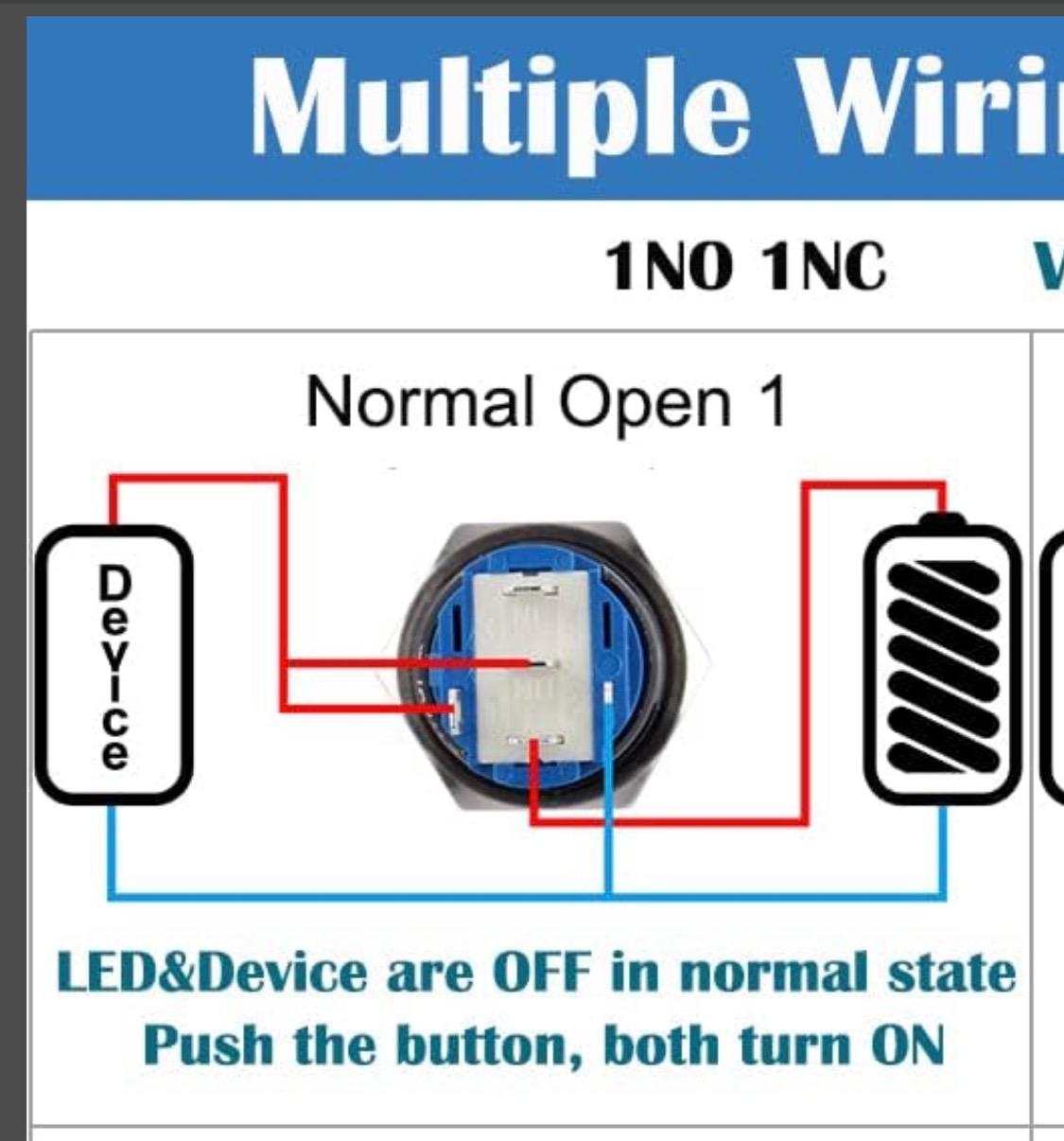

My man @IBMobile I knew you’d know how this should work. Thanks so much. Btw, ignoring the blue and green wires won’t affect the led lighting? The rudimentary drawings that came with the switch showed several wiring configurations and I was trying to use the one that when the the switch was pushed in, turned on the fan and the LED backlight, then when pushed again turned the fan and light off.- Auxiliary Fan Switch

I decided to ditch the thermostatic switch on my auxiliary trans cooler with fan and wire a switch into the cab instead. I got cute and ordered a push button switch with a fan symbol and blue LED backlighting. Can anybody tell me (or draw on a napkin) the best best way to wire this to a relay? Should I be using a standard Bosch 5 pin relay or something different. The wires in the pic are as follows: Black-negative Green-closed White- normally open Blue- normally closed Red-positive- Mini Skid Steer Track Problem

I know some of our members are knowledgeable and/or professionals with heavy equipment so I’ll see if anybody has any suggestions or ideas on how to fix this. I have a late 2004 Toro Dingo TX425. I pretty much just use it sparingly around the house, so it has a pretty easy life and isn’t used often. 2 years ago I was using it and the left side track slipped off. The lugs were beat up so I just bought a new track and kept going. About 2 hours of use with the new track and it slipped off too. I reread the track tensioning procedure and tried again. It worked for a few more hours and slipped off again. I’ve tried increasing tension with the same results. I inspected every component of the track system. The tensioner arm spindle bushing was worn so we tack welded it and I went ahead and put in new bearings in the tensioner wheels. The tensioner spring seems fine (not cracked). All the bogie wheels move freely. I don’t have another machine like this to compare it to, and I don’t want to disassemble the right side track for fear of messing up something that’s working fine. The link below shows the tensioner arm in the guide slot, there is play but I’ve be been told that’s normal. The other link shows the drive wheel, which looks like it “might” have a very very slight wobble, but it could be my eyes playing tricks. The pic of the track shows where the lugs have been worn when coming off the track, they probably have 5 hours of use. Can anyone think of anything I’m missing?- Blinker Fluid Maybe?

Sweet, back to the salvage yard!- Blinker Fluid Maybe?

It definitely has that same click you get when the blinker resets after you turn (that function is still working normally). I’ll look into the multifunction switch and see if anything obvious is happening.- Blinker Fluid Maybe?

Anyone care to diagnose this click sound? All the controls on the steering wheel are working (cruise, horn). - Dodge 2500 OEM Hitch Receiver Failure