- Replies 45

- Views 9k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 9 posts

-

Cowboy 8 posts

-

AH64ID 6 posts

-

portlandareae28 4 posts

Most Popular Posts

-

Pre vs post is a variable that is generally linear with boost. There is about a 100° difference for every 10 psi of boost. This was a rule of thumb I had heard and after running a pre and a post turbo

-

If you use the engine running method, you get extra redneck points for stuffing a piece of firewood in the exhaust pipe while doing it.

-

I drilled mine engine off, put grease in the grooves, and pencil magnet when completed. Bumped the starter a couple times to blow any small bits through before officially starting it. Done this twice

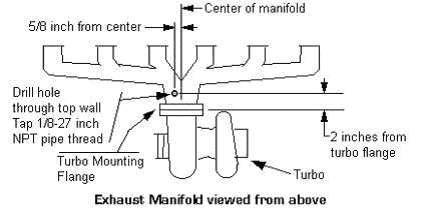

EGT gauge is back up and running, however, the probe is after the turbo. In my previous trucks I have been in the exhaust manifold, and 1200* was the peak I ever wanted to see.. My question is, because I can't move the probe before towing this week/weekend. What temp would you guys say is a conservative number to stay at or below?

Thank you