- Replies 5

- Views 4k

- Created

- Last Reply

Top Posters In This Topic

-

Haggar 2 posts

Haggar 2 posts -

Stanley 2 posts

Stanley 2 posts -

Dieselfuture 1 post

Dieselfuture 1 post

Popular Days

Most Popular Posts

-

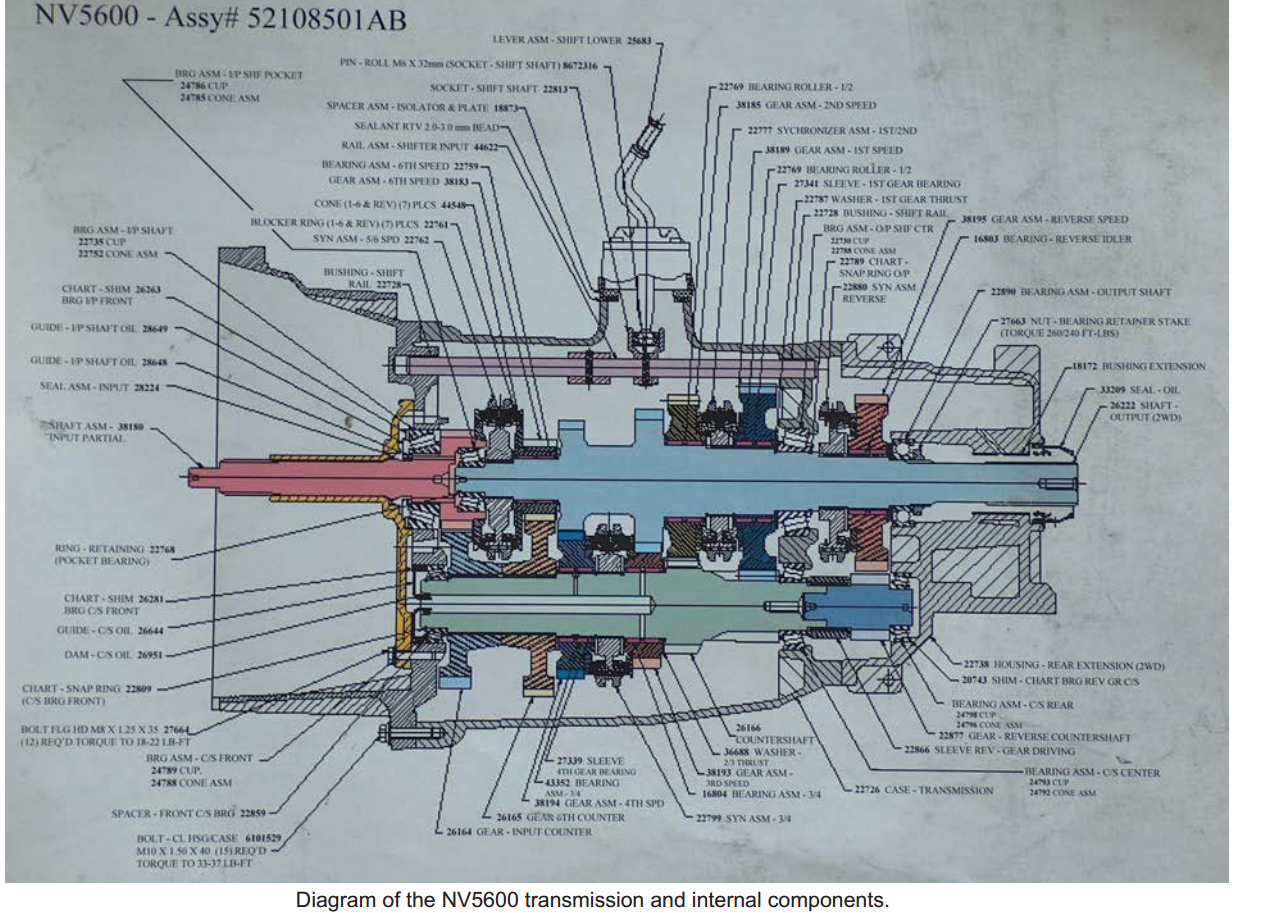

Ahhh I got ya. If this is a correct cross section, Unless you need to know the end play of the dark blue short shaft (reverse) in the lower right, you can get all you know with tail housing on. (

-

If your in there do it all! Not worth just one or two. All Bearings and all synchros. This time I skipped doing the needle bearings. All bearings looked great but I got the whole kit and kaboodle so n

So after I rebuilt my t case I rebuilt my 5600.....Whew what a job but its back together but Im having trouble finding the correct way to measure endplay on main shaft and counter shaft etc.

Its all together minus the middle cover inside the bell housing. and I have new shim packs for both shafts. I might have went to far and might need to remove the tail housing to obtain correct measurement... Can anyone shed light on this method. I know what needs to happen, just not sure how to go about it lol. And I know specs are .002-.006 endplay. Thanks.