- Replies 10

- Views 6.5k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 4 posts

-

BennyGGG 4 posts

-

Haggar 1 post

-

Dieselfuture 1 post

Most Popular Posts

-

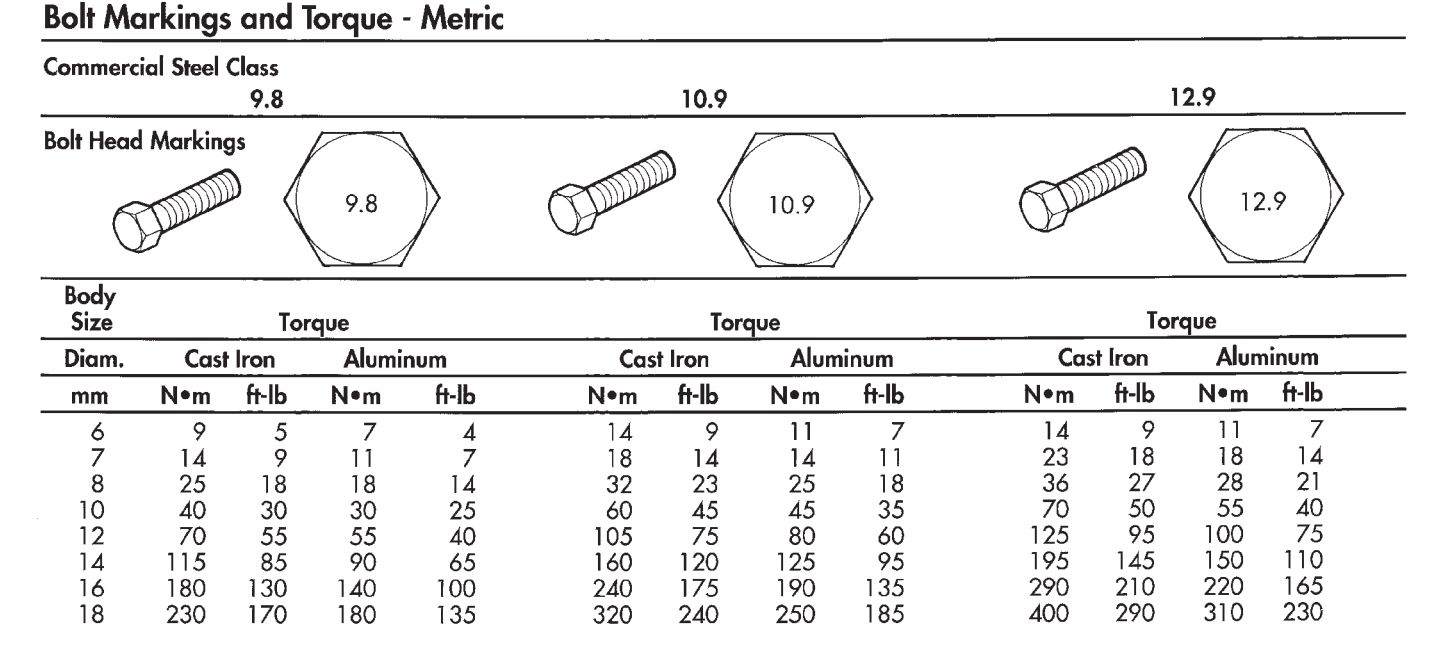

Yeah the manual only talks about the fronts. If I picked the part correctly that is an M14 bolt. (06504691) It looks like it says 10.9 on the head in your picture. Th

-

I always just got them snug, if I had to guess 65-70ft/lb

-

Be careful. I did the front caliper frame bolts in the front with loctite. Needlessly to say the loctite and being torqued in it was so hard to remove I broke 4 sockets just using a breaker bar to rem

Can’t find the torque spec for the rear caliper bracket. 2001 Cummins ram 2500 with ABS and rear disc. Appreciate any help ??

FSM 5-3 is where I was looking. It’s just not clear to me.