- Replies 26

- Views 2.8k

- Created

- Last Reply

Top Posters In This Topic

-

DoggyDiner 11 posts

-

dripley 6 posts

-

Mopar1973Man 5 posts

-

IBMobile 2 posts

Most Popular Posts

-

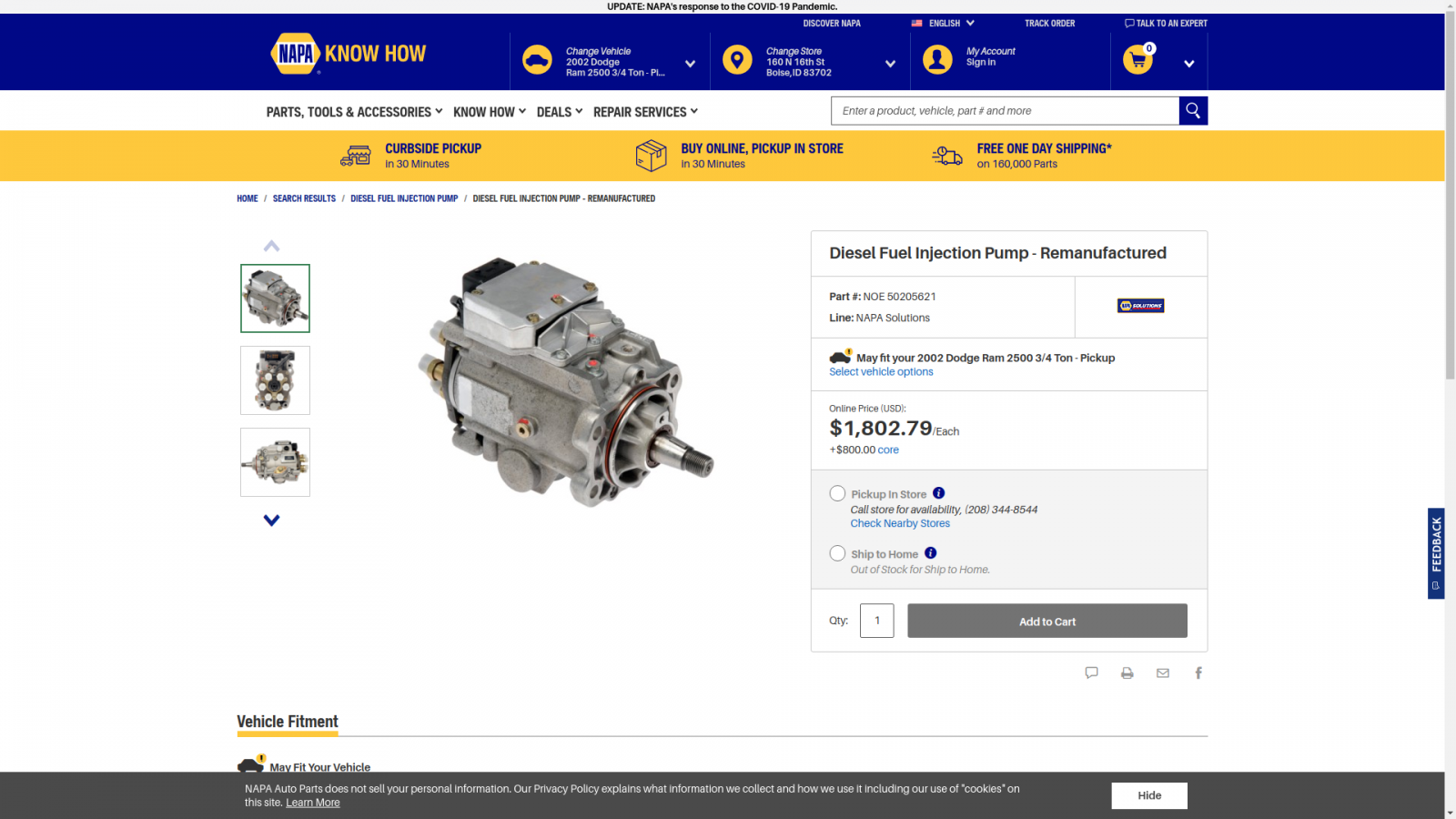

I just sold a DAP VP44 injection pump for $1,100 here in the valley plus the labor. Nice to have my vendors @dieselautopower and my sale tax permit I get these pumps at cost and make a bit of profit.

-

not worth killing anyone over $30 or so. These are really low margin items... unless we sell them for $1800.

-

Hey, @dieselautopower you took away all my fun...

Last November my original LP and IP failed. Both were replaced at the same time. The LP was a Napa stock replacement. It failed when I got home from a 900 mile trip. I took it to a shop and they diagnosed the LP failed. When I got it back with a new LP and pressure gauge, the LP failed after 2 weeks. I took it back to the same shop, it's under Napa's warranty, they replaced the LP again. Got it back, 2 weeks later the LP failed. Being fed up with the Napa LP dying, I researched online on aftermarket pumps. I settled on the FASS 95gph mounted close to the fuel tank. Got it started and running great. This past weekend, I drove it to pick up a heavy load of wood, the weather was warm but not hot. After I loaded the wood I tried starting it, it took a longer crank than usual, but it did start. When I got home I tried it about an hour later, same thing, longer crank time than usual. I have another long trip in a couple of weeks and don't want to be stranded. Is it possible that the IP is going out or that the LP has too much fuel pressure for the IP? I have the add a fuse connected in the cab of the truck to fuse 9.