- Replies 31

- Views 8.5k

- Created

- Last Reply

Top Posters In This Topic

-

piñon&juniper 14 posts

-

Tractorman 5 posts

-

Mopar1973Man 3 posts

-

IBMobile 3 posts

Most Popular Posts

-

How to install a lift pump relay. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/59_fuel/installing-protective-lift-pump-relay-r501/?tab=comments#comment-55

-

Stock lift pump lead from the ECM has no relay and is power directly through the ECM. If there is issues with the lift pump circuit the ECM needs to be sent to @Auto Computer Specialist for inspection

-

Ok, I have an Airtex fuel pump plumbed in my fuel system with the fuse for it pulled. It is used as a backup if the belt breaks on the mechanical pump and is also used to prime the fuel system when c

I've got my 2001 2500 5-speed 4x4 down with a lift pump problem.

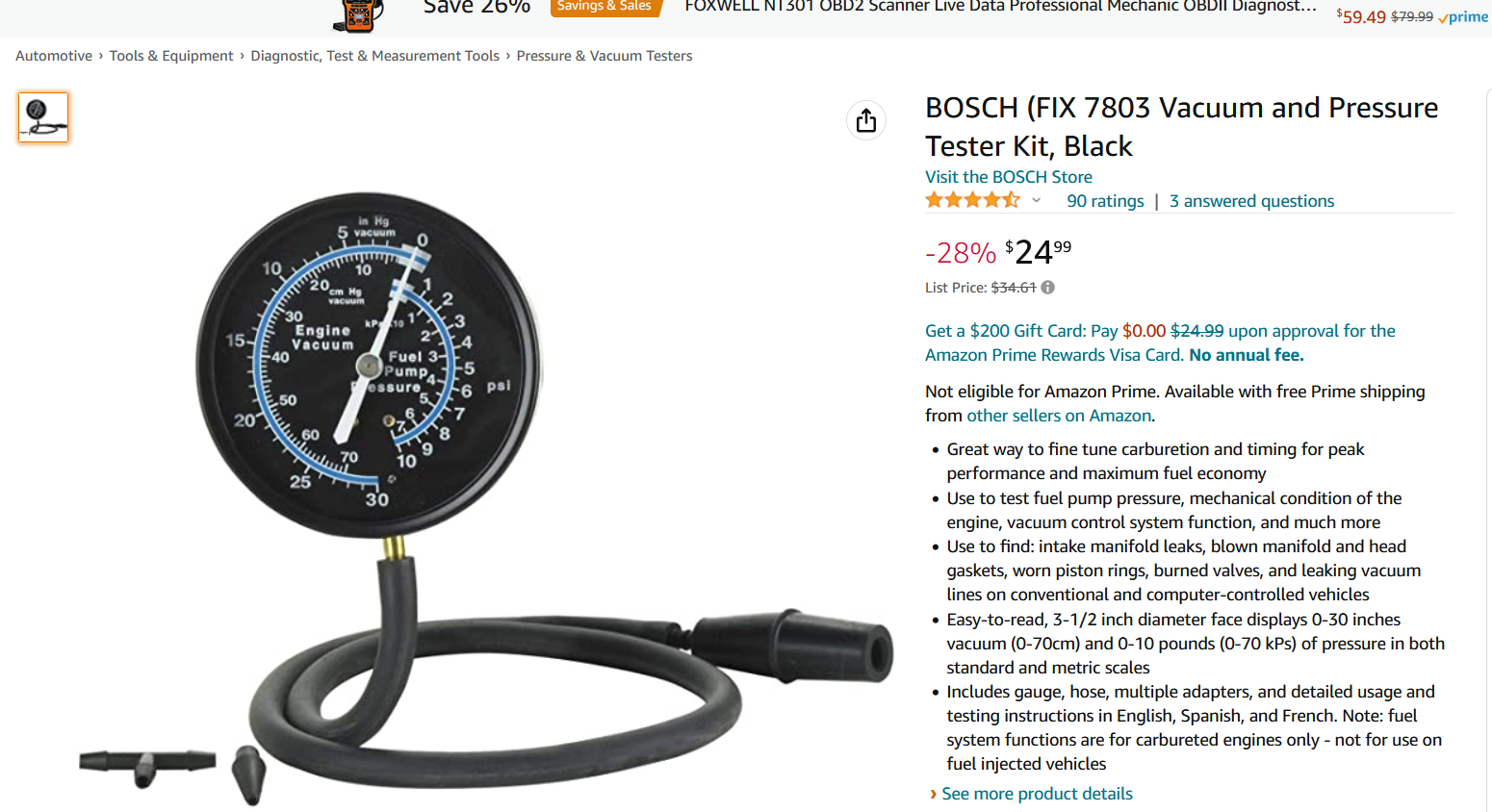

Currently the newly replaced (in-line style, original location on engine) pump is primed and working during starting and maintains over 15 psi (that's the my of my gage). If the truck has sat for a few minutes, it will turn on briefly when the ignition is turned on, and it responds to blipping the starter by turning on for 25 seconds. I can hear good fuel flow returning to the tank (which I just cleaned up when replacing the fuel sender). Once I got the fuel circuit bled of air, it started just fine, but as soon as the engine starts, the lift pump shuts off. The injection pump is apparently able to pull enough fuel to keep idling, but can't rev up much- obviously it's starving for fuel. Gage slowly drops to zero.

I've swapped relays around for the fuel system and the ASD, with no improvement. I replaced the earlier lift pump with a fresh one, though the earlier one wasn't very old. There are no codes showing.

My search of the forums suggests that the ECM might have a burnt out circuit that runs the lift pump while the engine is running as opposed to starting. If that's so, I don't know why it would be, and I'd like to positively diagnose it before embarking on that repair. I have had strange lift pump behavior, including drops in pressure that vary with load but also come and go intermittently. I did replace the lift pump that came with the truck from the previous owner after I had is pressure drop to zero at times, and at this moment I have just replaced the one I put in, because I thought it was causing the problem... not so, apparently, so I guess I have a working spare.

Can anyone point me to any discussions that address this, or provide any further troubleshooting guidance?

If my ECM is the problem, I'm more tempted to set up a new relay off some other signal source to turn the pump on, in hopes that I can retain the shut-down function that would trigger in case of a wreck. I'm guessing a new or repaired ecm isn't in my budget.

Thanks for any ideas.