All Activity

- Today

-

Thestory79 joined the community

- Yesterday

-

Mopar1973Man started following Memory and system usage challenge

-

Memory and system usage challenge

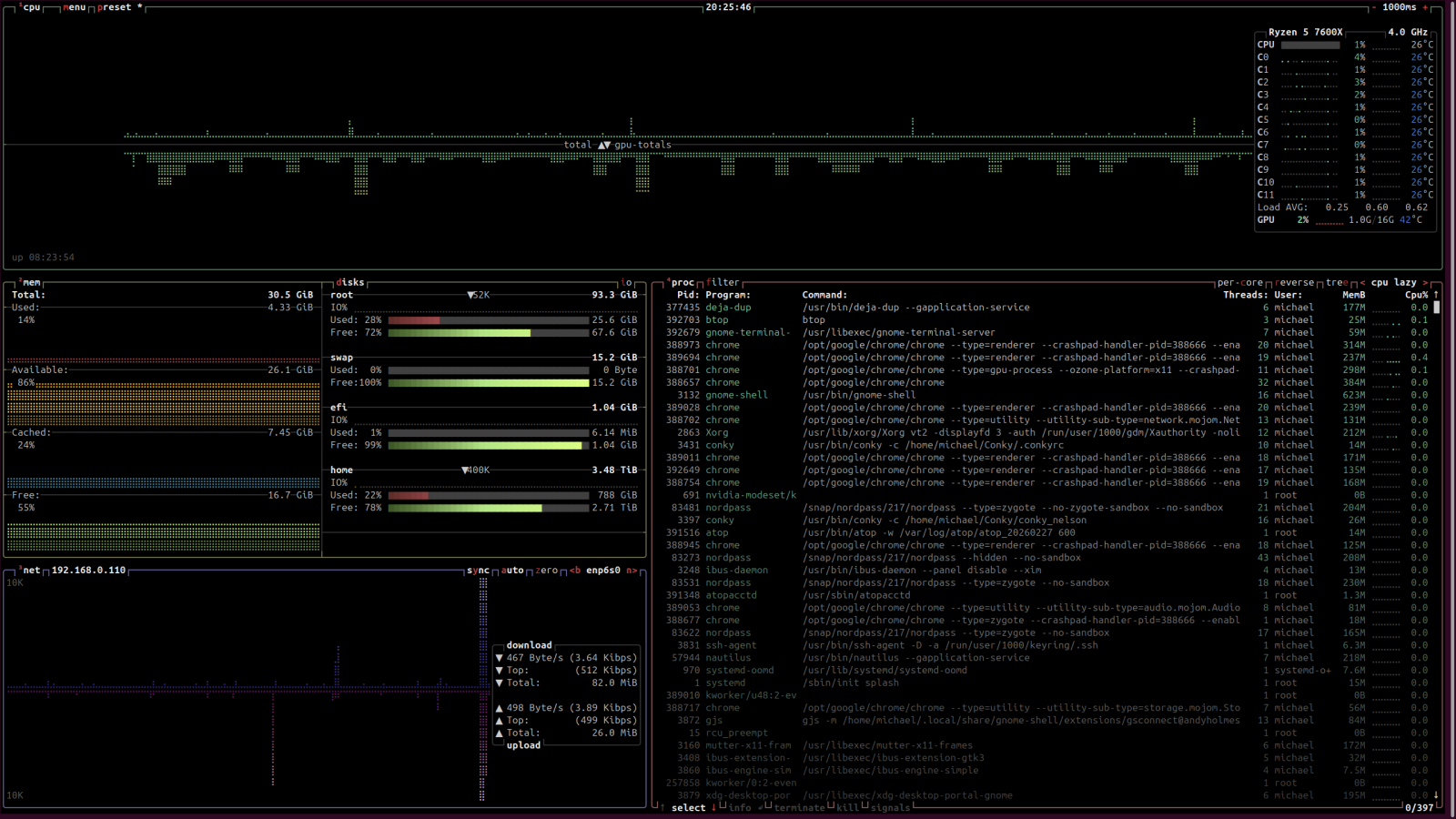

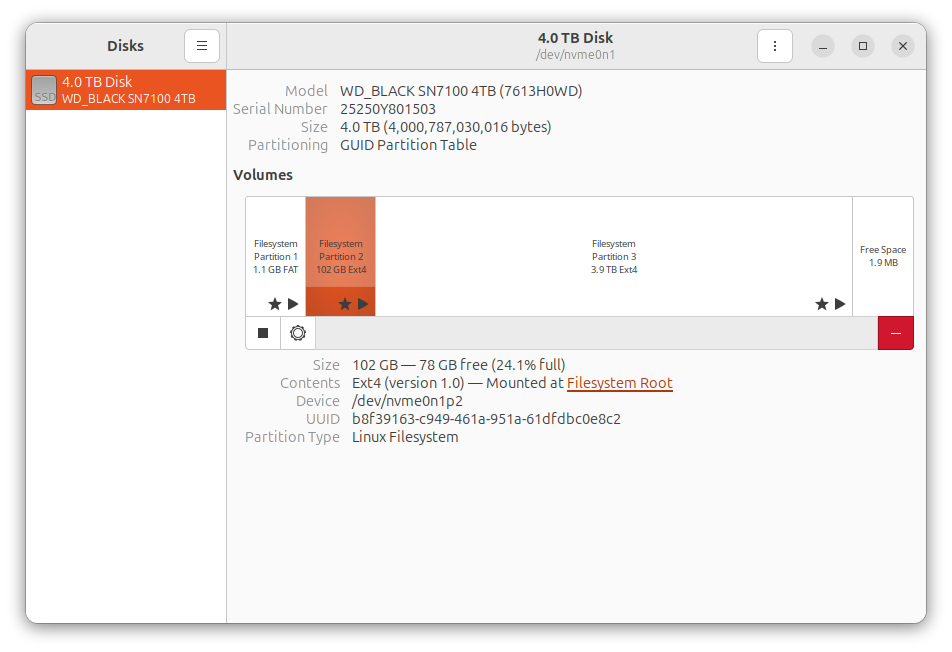

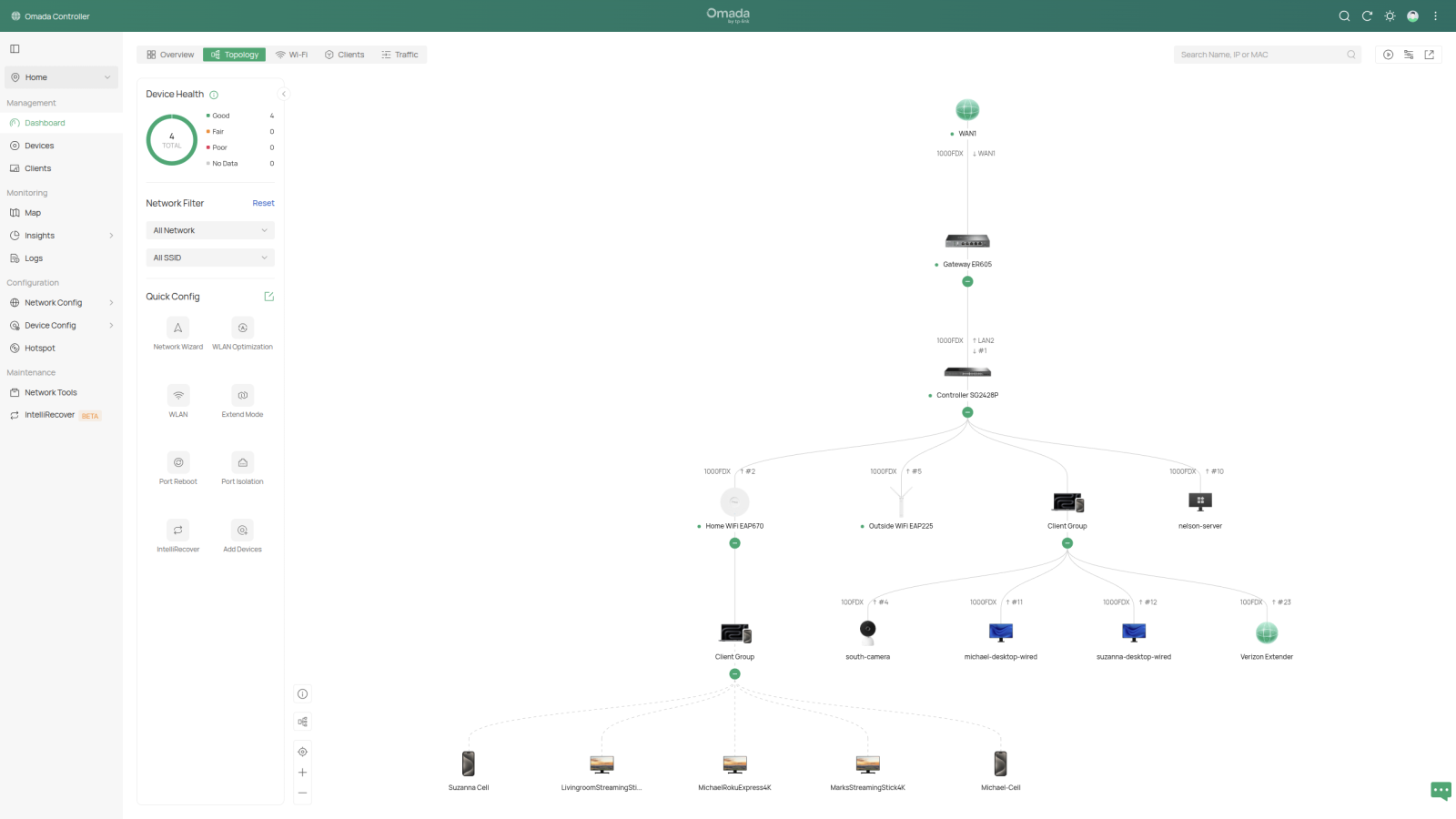

I'll show you all my workstation. 12-core AMD processor 32 GB of RAM and only barely 15% used 4 TB hard drive M.2 chip (22% used for home data, 28% used for the OS system (root) 1Gbit Network (CAT6 Cable) As you can see, my workstation has all the common-sized stuff that most Windows PCs today are build with. So now...I want anyone to post up the amount of memory used on their Windows 10 or Windows 11 PCs. My uptime is low because I had a kernel update for the machine, so a reboot is required. Hard drive usage is low for 4TB hard drive yet. Perk bonus for linux users. No more defragging hard drives, no more anti-virus software, nor malware scanning of your machine. Being that I isolated my OS system to its own partition this makes the system secure too. Since the OS system files are tucked away like this, and if there is any reason I need to reinstall my Ubuntu, due to a screw up on a setting or a crashed system, there is no problem. I can reload the operating system completely with no ill effect to the personal data. This is done by partitioning your drive so the operating system is not part of the home folder. Now, during the reinstall, just notify Ubuntu where each folder is and tell the software not to format the home folder. It will remain untouched. The only catch is having to reinstall your other software. Anyone willing to show off their Windows PC?

-

Old CAT5 cables, replacing with CAT6 cables!

Cables came, and I just found out the TP-Link switch I have can manage up to 48 Gbit signal across the entire network. All ports are limited to 1Gbit signals. So the cables for the workstations are top-notch and have a ping time of less than 1ms. I could have done the same with CAT5e and been cheaper, but I like the idea that I've got shielded cables now that are CAT6 rated. The best I've done is remove noise as a problem. I was showing @Tweety Bird the difference between CAT5 and CAT6 is that the jacket is thicker, with shielding foil/wire. This CAT6 is solid copper and not CCA (Copper Clad Aluminum). Then the divider in the middle to separate the 4 pairs.

-

New Kicker Speakers for Beast!

I found new cables for a pair for the left and right rear door for just under 30 bucks. Harfington55275106 Rear Left Right Side Door Latch Cable Fit for Do...Buy 55275106 rear left right side door latch cable fit for dodge for ram - pack of 2 black at Harfington, get more hood release cables in various size.

-

New Kicker Speakers for Beast!

Use plastic weld. Stuff holds real good!

-

Threadzy started following New Kicker Speakers for Beast!

-

Beast is falling apart!

I love mine I finally got the rear camera mounted at the license plate. Great view and wide angle view as well. Touch screen allows for tipping the camera up or down like you would move your mirror. My setup required both directions of the camera to be flipped, and it works great. Records the GPS location in real time with your video, so position, speed, and direction are all recorded and will display even your road speed of recording, and even if you're talking in the cab. Mirror has voice commands as well.

-

Beast is falling apart!

@Mopar1973Man how do you like your wolfbox? I been seriously thinking about getting one for my 19' Ram and prolly my 2nd gens too... I know there's a couple of different models, what do you have? I want one that is on a loop. Idk how big that loop is, guess that depends on your SD card size. It seems to fit the bill, dash cam plus rear view camera, there ads are all over my fb lol....

-

Stanley started following Beast is falling apart!

-

Mopar1973Man started following ghost revving at idle

-

Beast is falling apart!

With 503K miles on the Beast alot of stuff is going bad and falling apart. I need to take advantage of things I have access to and the time I have available when the weather is better. Plastics have been ordered, and I'm going to start restoring Beast. I just ran into a guy just down the road from me who has a straight rear bumper and will to just give it to me. Bonus!

- Last week

-

Beast is falling apart!

Sounds like regular maintenance for one of these pickups. Lol . I need to also replace the dash in my pickup right after I finish the lift pump fiasco next month when I get back home

-

kbf98520 started following Beast is falling apart!

-

Beast is falling apart!

Beast is falling apart completely. The plastics are failing left and right. I've got to pull the dash apart to fix a speaker problem. @Tweety Bird telling me just order the plastics and get them coming. I placed an order through LMC truck for the new plastics for the dash, and then found a smaller part supplier that has the rear quad door cables for a pair at $30. Cheap! Yesterday I was out and had enough dry weather to install the rear speakers and then move the rear camera to the rear bumper. The Wolfbox dash camera works awesome. New pair of door cables for the rear quad doors and then new dash plastics!

-

Mopar1973Man started following Beast is falling apart!

-

Predictable Stalling

One more thing to possibly verify, if you haven't done so already. Temporarily jumper an LED test bulb to the wire at pin #7 at the VP44 (the 12 volt supply from the fuel pump relay). This bulb should always be lit while the engine is operating. If and when the engine dies, note whether or not the bulb stays lit. If it stays lit, then at least you know the wiring and fuel pump relay are working properly. Interesting regarding the reduced frequency of the symptom after adding two-stroke oil. Could be something to it, or just coincidence. You have done a lot of work trying to figure this out, so I personally would not draw any conclusion just yet. John

-

Predictable Stalling

The .112v was the injection pump shutoff wire. Thanks for the suggestion. I’ve changed to 0.5v. I heard the Timbo apps aren’t ideal though due to them being default .65v or something? The issue ended up being the VP44 after all as far as I can tell due to one test: adding 2-stroke oil to the fuel. The symptoms have greatly been reduced since doing that, and on many occasion doesn’t even stall. It’s a bummer, but it’s nice to at least be fairly certain.

-

ghost revving at idle

Hello, I am new here. my son bought a O2 24 valve Cummins a number of months ago without knowing much about it history. We've been trying to figure out what's going on with this ghost revving. Without touching the gas pedal after you start it it'll start quickly jumping up to higher RPMs sometimes getting a little scary and staying there. It worried us enough to where we brought it to our local mechanic.. he had it for over a month flushed all the fluids and did some other maintenance, but ultimately couldn't figure out the main problem we brought it in for. I've had it back home for a couple weeks and I have ordered and installed a new genco alternator., installed a new Timbo APPS, I am done a fair amount of testing. It's not showing any codes with my code reader and this is also something the mechanic was frustrated by. he couldn't get any codes to show up. I figured I had it nailed with the new APPS and alternator. This is mostly because I tested for AC ripple and tested high. Then low and behold, none of my attempts have had any success, and basically just left me frustrated after wasting a lot of time and money. Today I'm gonna try rerouting the wire that some claim is affected by the electromagnetic field coming from the alternator. I'm not very confident that this will do much but I'm gonna try it anyway. I'm also gonna check my grounds and tighten them clean them whatever. I thought I'd ask on here to see if anybody had any ideas before we tow it to a mechanic a long distance from our home who specializes in these trucks, because I'm nearly to that point. Thanks.

-

lcmon started following ghost revving at idle

-

lcmon joined the community

-

New Kicker Speakers for Beast!

This turned into a problem child to a degree. My driver's side rear door release cable for the inside door latch broke at both ends of the cable. Urgh! I'm going to repair the end hopefully with super glue and atime to till I can order the right cable. 20+ year old plastic is brittle. I've got to pull my dask bezel, and I'm sure more of it will break now, too. Argh!

-

jansenjosh joined the community

-

aualliso joined the community

-

New Kicker Speakers for Beast!

The other problem you starting to see how often im capable of working on my truck which is all based on weather now.

-

Old CAT5 cables, replacing with CAT6 cables!

Cables due to be here tomorrow. More to come.

-

New Kicker Speakers for Beast!

Now today I was wiring up the rear speakers and then lost connection on both left speakers.I pulled the front left apart and recrimp the connector solved. Now the left rear is dead no signal. I think a darn mouse chewed the wires in the dash. Ugh! More to come.

-

SS7 joined the community

-

Michael Brophy joined the community

-

dodgeballgazer joined the community

-

Old CAT5 cables, replacing with CAT6 cables!

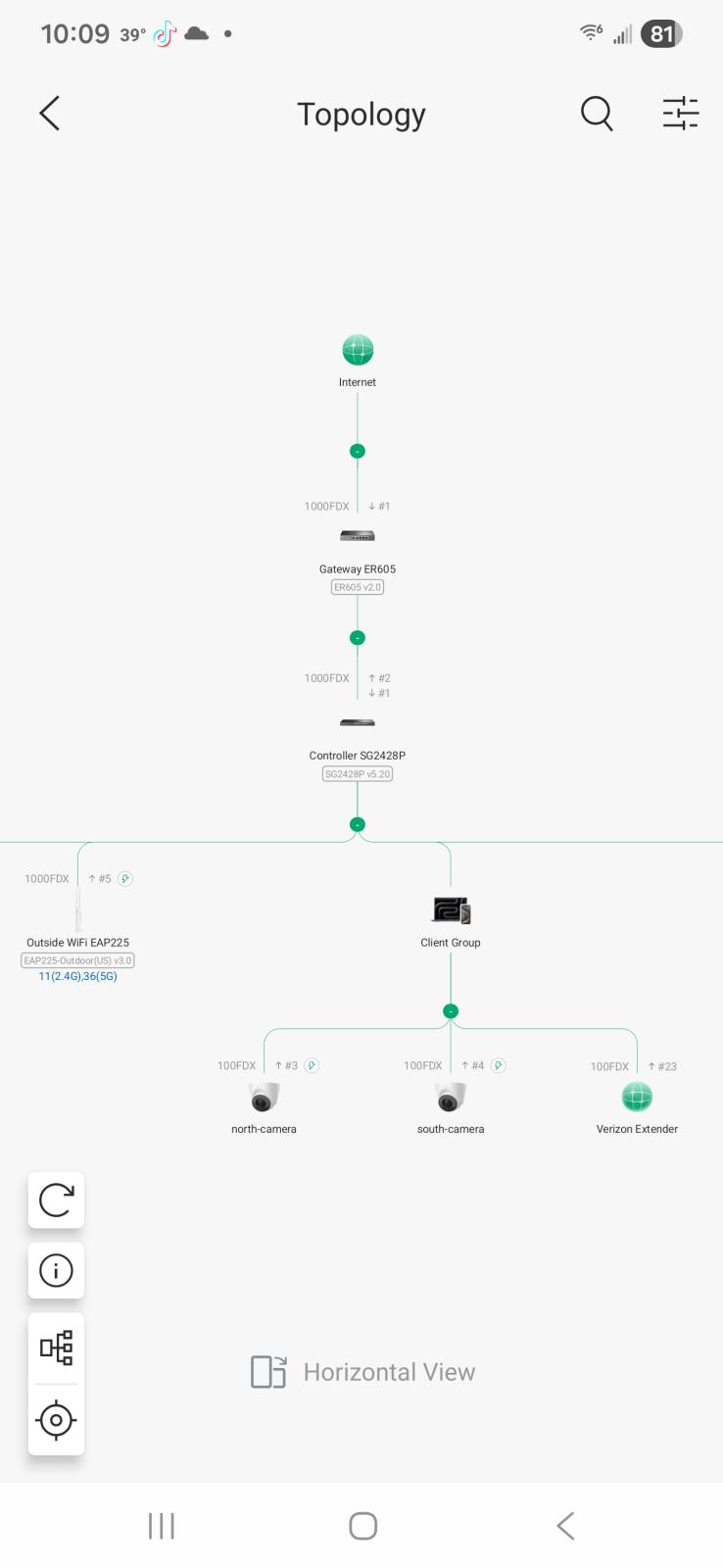

Yeah. I would of bought a box and ends but I already have a 500 foot roll of direct bury outdoor CAT6 cable. I've even got two new cameras I want to mount to pole out in the yard. I need to clean up the yard in that spot so I can place a pole. Shop trash heap is in the way. Then run from the switch to both PCs is just barely 16 foot at the longest. 3 cables coming to replace the CAT5 cables. What bandwidth does your cameras run at? Mine seem to only hook up at 10/100 shown by the network. Just the Verizon extender too. Dang cheap CAT5.

-

Old CAT5 cables, replacing with CAT6 cables!

That works. When I installed my security Cameras I used CAT 6 for my video and power source as it was cheap and easier to hide. So I picked up a large 1000 ft box of cable, ends and the crimp tool. Its nice being able to make a cable to the exact length i need.

-

Lund1990 started following Old CAT5 cables, replacing with CAT6 cables!

-

wpbvette joined the community

-

Power Steering Pump / Vacuum pump Conversion

Here are some threads to peruse that may offer some insight. I have performed both mods about 1 year ago - well worth my time and expense. John

-

10-4 App

Weird. I would consider either grabbing a small sample and testing both. Maybe catch the delivery truck and talk to him. See if your state has different policies. Last time I caught Maverik delivery I was able to find how much additives are being added.

-

10-4 App

No Edge tuner (just there as a monitor), less than 30k on a reman motor with NEW injectors and no bio-diesel...... that and the mileage changes in accordance of auto or semi lanes when purchased.

-

Power Steering Pump / Vacuum pump Conversion

Im gonna need to do some more digging on this apps "delete" and this conversion. Very interested, possibly needs to be a article 😉

-

Stanley started following Power Steering Pump / Vacuum pump Conversion

-

10-4 App

Your problem could be the Edge Juice most likely too advanced in timing. Then how many miles on your injectors? As injectors wear out the pop pressure falls off for every 10 bar drop the injectors gain 1 degree advancement. This mean you would have to reduce timing in your tune to keep numbers up. Then the high cetane of biodiesel is lower BTUs but also needs less timing (retard) to burn efficiently. Quadzilla im starting at 12°BTDC at 1500 RPMs. Im not sure if your Edge has any timing adjust.

-

Mopar1973Man started following 10-4 App

-

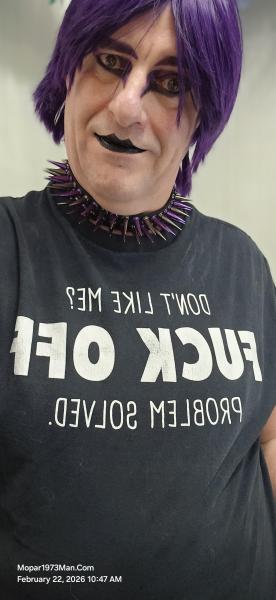

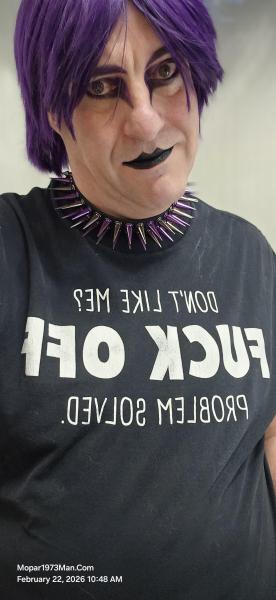

Titanium

My adventure of having a second run at bladder cancer and going back and forth to chemo treatments and surgeries. "Titanium" the character, kept me going and helped me with depression and stress of the idea I might not make it. I've made several new friends and found a new way to enjoy life as I continue to dress up and do my Titanium makeup. I'm always taking my adventure out into the public and share my artwork with everyone!

-

20260222_104448.jpg

20260222_104448.jpg

-

20260222_104500.jpg

20260222_104500.jpg

-

20260222_104510.jpg

20260222_104510.jpg

-

20260222_104533.jpg

20260222_104533.jpg

-

20260222_104757.jpg

20260222_104757.jpg

-

20260222_104800.jpg

20260222_104800.jpg

-

20260222_104806.jpg

20260222_104806.jpg

-

20260222_104807.jpg

20260222_104807.jpg

-

20260222_105445.jpg

20260222_105445.jpg

-

20260222_105453.jpg

20260222_105453.jpg

-

20260222_105458.jpg

20260222_105458.jpg

-

20260222_105502.jpg

20260222_105502.jpg

-

20260216_101906.jpg

20260216_101906.jpg

-

20260216_101913.jpg

20260216_101913.jpg

-

20260216_102016.jpg

20260216_102016.jpg

-

20260216_102020.jpg

20260216_102020.jpg

-

20260212_112151.jpg

20260212_112151.jpg

-

20260212_112203.jpg

20260212_112203.jpg

-

20260212_112530.jpg

20260212_112530.jpg

-

20260212_112535.jpg

20260212_112535.jpg

-

-

Old CAT5 cables, replacing with CAT6 cables!

@Tweety Bird asked me to send some documents to her computer workstation. I'm getting a message of "No Route". I check the network switch for her PC to be present. Nope is not even registered in the network. I've been working with damaged scraps of cable, trying to get by. Nope! I'm done. I jumped out on Amazon and found a 10 GBit CAT6 cable rated for 10 GBit. I'm going to upgrade the 2 lines between the workstations so that large data moves can happen quickly. I just remember I need to order one more short cable about 6 feet tonight, so the server and the two stations will all have 10 GBit bandwidth, and I could move data like I have the internet backbone. https://www.amazon.com/dp/B00G9BN4L6?th=1