- Replies 36

- Views 10.4k

- Created

- Last Reply

Top Posters In This Topic

-

CumminsHokie 17 posts

-

Me78569 7 posts

Me78569 7 posts -

Mopar1973Man 4 posts

Mopar1973Man 4 posts -

Dieselfuture 4 posts

Dieselfuture 4 posts

Most Popular Posts

-

I just recently graduated and had the craft of scientific writing beaten into my skull only to continue using it with my job...who would have thought?! The dead pedal issue happened about

-

Welcome to the greatest cummins site ever. Sounds like you're on the right track checking the alternator. I'm not sure if your scan gauge can monitor your apps, or you can use a Multimeter and ch

-

Thanks for the optimism dripley! I was actually just monitoring it again and it seems to have jumped up to 17% not that that matters I don't think. I wondered if it was just a scan gauge thing. I'm ex

Gents and ladies,

This is my first post on any forum ever but I figured mopar mans forum would be the best. I'm really stuck on what's happening with my truck and it's so annoying because I just got it running beautifully not too long ago. I will start off with some back ground of the truck and the problem.

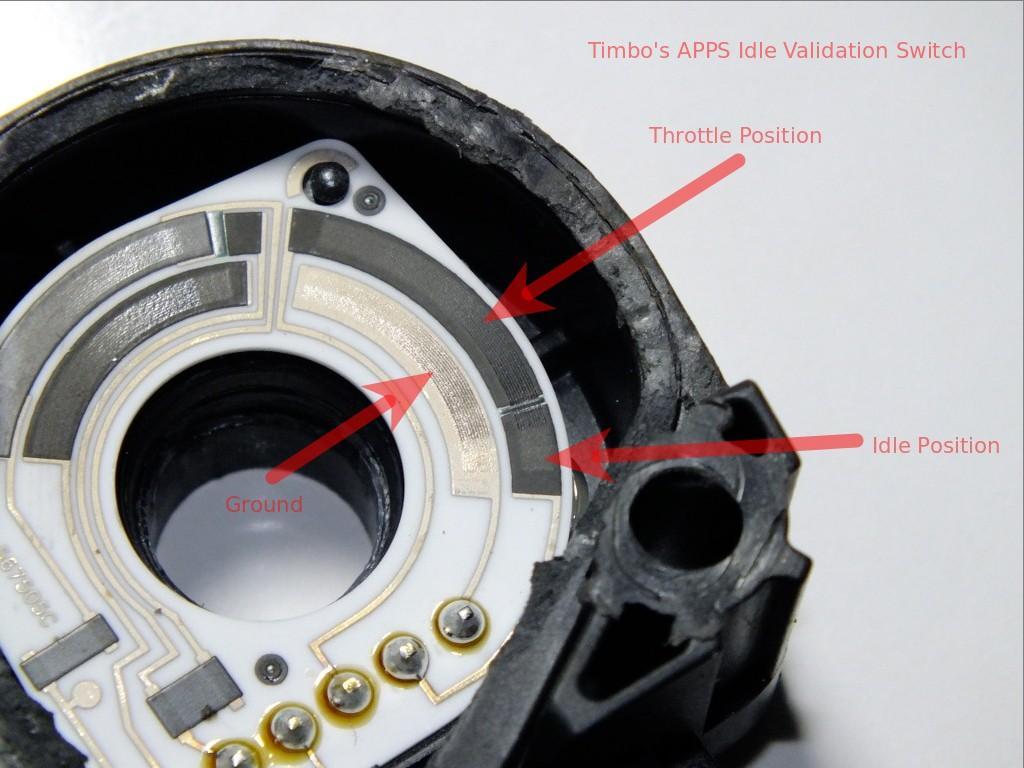

Its a 2001 with about 210k miles, 2wd, automatic trans, bhaf air filter, 4 inch straight pipe, and until recently (I took it off thinking maybe it was causing my issues) an old quadzilla adrenaline that replaced my super chips (I say old because it is one of the first boxes made and I got it used, had the big power resistor replaced, then tested at quadzilla and verified). Now the problem started about a week ago when I noticed that my rpms were kind of bouncing around at 1000 when coming to a stop from higher speeds. I would be doing about 50 and then let off the accelerator pedal, apply brakes, and once in maybe 2nd gear the rpms kind of bounced at 1000 and you could hear it in the engine. They would then return to about 750 once below say 10 mph. This happened for 2 days and on the second day I arrived home and placed the truck in park and noticed it was idling at 1000 rpms. I also noticed a very random, intermittent spike in the rpms as it sat there idling and could hear it in the engine. I'm not sure what a miss sounds like but that's my best guess. This is when I removed my adrenaline. The next day the problems persisted and I noticed that the truck was running rougher than usual. I hooked up my scan gauge 2 and saw that my tps was at 1 and was spiking to about 12 at all times. Once above 12 or so it would stop spiking. As a quick fix attempt I turned down my timbo apps until the rpms sounded about normal and then reset/calibrated the apps. The tps is still stuck on 1 and spiking to around 12 randomly.

I recently replaced my iat sensor (not with a CUMMINS part) as it was faulty and was causing dead pedal issues so I unplugged that thinking the cheap sensor I bought was causing it. No luck. I then unplugged my map sensor as I've read many times that this cause rough idling. No luck. It has also been cleaned recently and seems to be functioning properly per my scan gauge. Since readjusting my apps the rpms have come down a little but are still high in park and neutral only(goes to normal when in drive). The only other information I could see worthy to include is that when I had the quad on I didn't tap the pump wire so I only had levels 0-2. When driving with it on 2 or 1 I noticed what seemed to be the tc locking and unlocking and it got more noticeable as the levels increased from 0-2(can't really feel it with it on 1). I assumed this was because it is an old box but idk that it could have been creating additional ac noise?

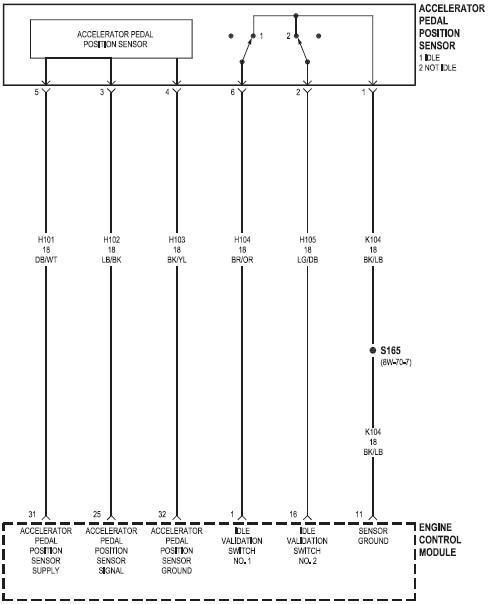

I havent been been able to do any troubleshooting but when I get time this weekend I will be first checking the alternator for excess noise (even though it's fairly new) and then testing the entire apps harness per instructions found on this site. The only other thing I can think to check is the camshaft position sensor. Any thoughts? I have no codes being thrown and no dash lights illuminated.

Any suggestions would be greatly appreciated and I really want/need to get this thing fixed. She's the love of my life.

forgot to add that I also have a raptor 100 and gauges, though glowshift. Fuel pressure has always been 18 at idle and 16 at wot. It seems to be a little lower now from what I assume is because the truck is idling higher. It sits closer to 17 idling in park.

Edited by CumminsHokie