- Replies 31

- Views 5.9k

- Created

- Last Reply

Top Posters In This Topic

-

Timburrr 10 posts

-

dripley 5 posts

-

Dieselfuture 5 posts

-

Mopar1973Man 4 posts

Most Popular Posts

-

I swear they hire retards for counter help, I've talked to few mechanics actually knew one pretty good from working out together back in late 90s and back then he was telling me diesel is where it's a

-

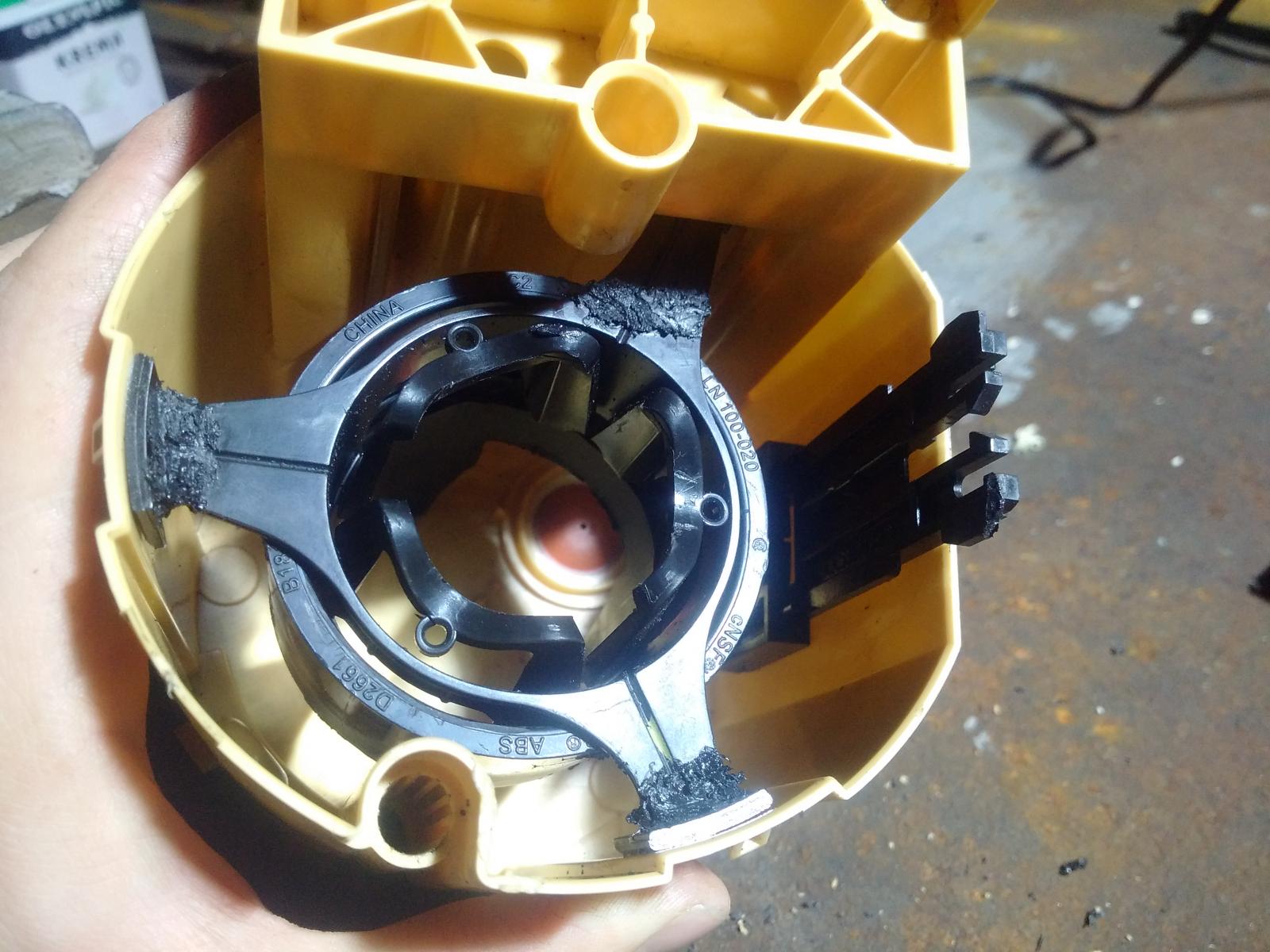

Thanks to everyone for the help. Especially the info that ABS is safe for diesel, that saved my bacon. Made a sort of support using 2" ABS and a double female fitting, then used a soldering iron to

-

I am not familiar with this pump and it does not appear to have a return line from the pump to the basket. My AD has a return directly from the pump to the basket in addition to what the engine is ret

Long story short, I am doing the vulcan draw straw mod in my fuel module and i have to make a bracket to hold the supply and return lines in place. Is mild steel okay to use for this? It would be 2-3" from the bottom of the basket of the fuel module so it would basically always be covered in diesel (I don't imagine it would corrode). It would be incredibly cheaper and easier for me to make it out of mild steel vs aluminium or stainless. I'd enjoy hearing thoughts on this.

While we're on the topic, they mention drilling holes in the side of the fuel basket, but this seems like it would be more prone to let fuel out than in. Is it necessary to drill the holes?