- Replies 31

- Views 23.3k

- Created

- Last Reply

Top Posters In This Topic

-

Mopar1973Man 11 posts

-

dripley 6 posts

-

Jwirth 4 posts

-

57pan 4 posts

Most Popular Posts

-

Bad idea. No need for the any wire mods.

-

Any news on this?

-

You keep making me want to kiss you. Someone had made the ATS modification to mine, so I unmodified it. I did keep the jumper from the APPS to the battery ground at the body. I figured adding an

Ok Gang...

I just had a wonderful phone conversation with Rburks this morning and his chasing his problems with his idle well he happen to mention the fact he did the APPS voltage adjustment and I like "OMG not again!" There is a article on the Internet that is wrote up wrong and need to be corrected and stopped.

Problem #1 - Voltage on label

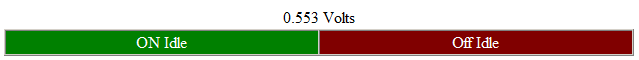

Everyone is trying to hit this voltage dead on... DON'T! This is the voltage that the APPS sensor goes from ON idle start to OFF idle state. You voltage MUST be BELOW this number.

Like on mine the voltage is .519. Don't set the voltage at this set it below this mark say .480 to .490 because as you add in voltage gain or loss during normal operation of the truck it might cross the mark and go off idle and you end up with idle set at 950 to 1000. Then find out your exhaust brake, high idle and a few other things don't work!

STOP! Don't set the voltage to the voltage on the label this is WRONG!

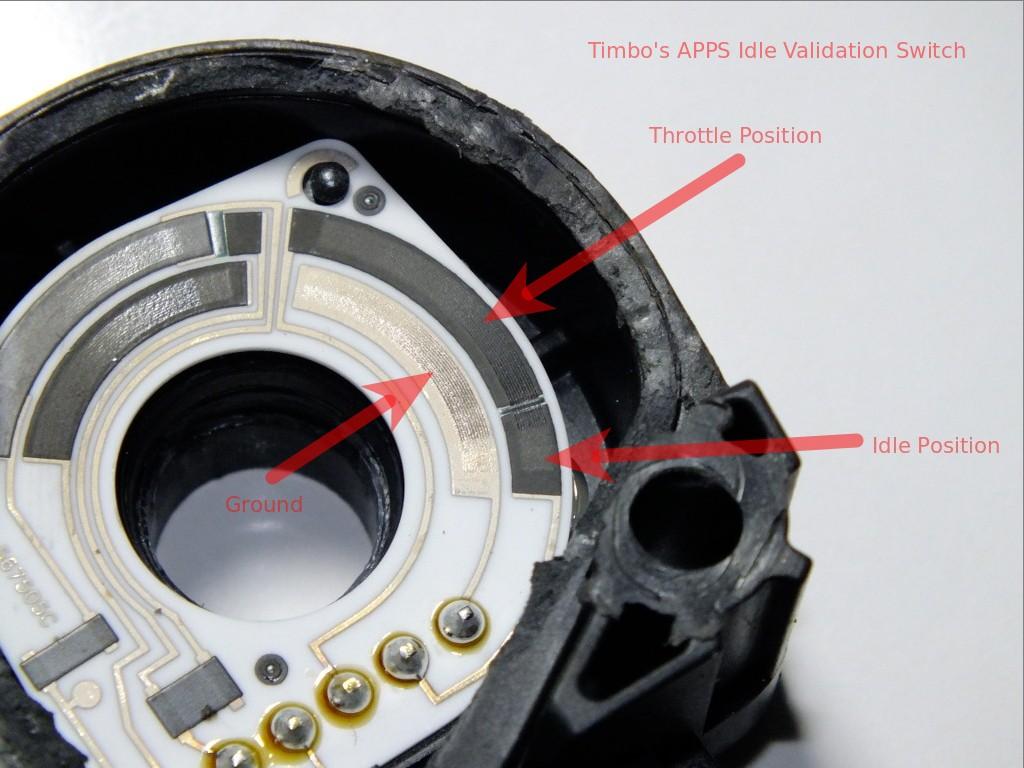

Like the timbo APPS you adjust to to the point you cross the dead zone and back off below this point 1/2 turn. Reason why is to keep the APPS from accidentally going to OFF idle state. As long as the voltage in the APPS sensor is below this state the the ON idle signal is given to the ECM and the APPS signal is basically ignored and idle programing is used.

Like for my example here the voltage on the tag is .553...

Now if the alternator or voltage of the system change a little bit you going to have issues of the voltage crossing back and forth over this boundary. Please set your voltage BELOW what on the tag by about 0.020 volts to insure the voltage is low enough to put the APPS sensor in ON Idle state.

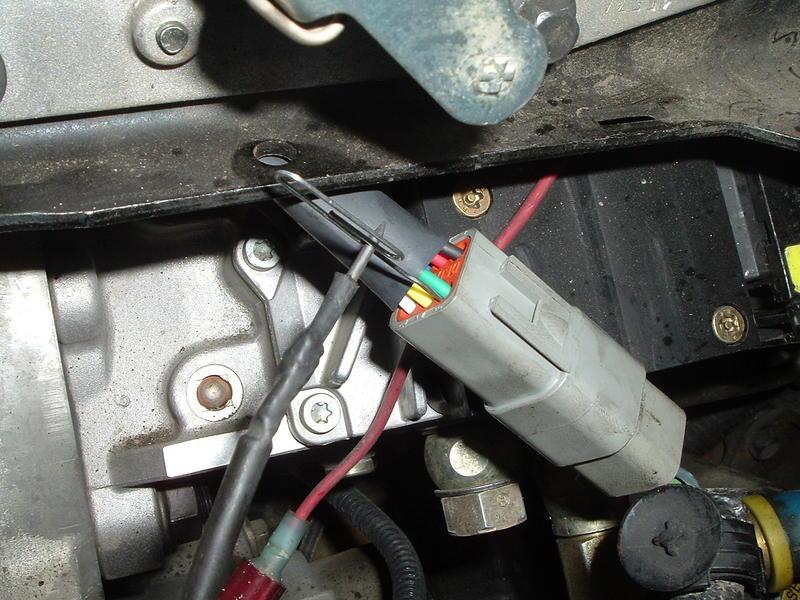

Problem #2 - Where to measure the voltage?

I do know why they started measure the voltage at the PCM in concerns of the TQ Conv Lock up problem but this is wrong too. Now if you go over to my wiring diagrams here...

http://mopar.mopar1973man.com/cummins/2ndgen24v/wiring/wiring.htm

And now look at Page 1 and look at the PCM on the right at pin #23 you see its labeled ACC PEDAL POS. You think this is tied to the APPS?! Nope... Now switch back to page 3 now at look at the ECM on the right you find the wire at pin #28 on the ECM label ACC PEDAL POS SENS... But now look at all 3 pages this this Orange/Blue wire doesn't connect to the APPS sensor at all but it does pass the information to the PCM after it passes through the ECM (if there is any processing). So now look at Pin #25 on the ECM and you'll see it has a direct connection with the APPS. So if I was going to adjust the stock APPS sensor for voltage I would measure right at the APPS sensor or at the ECM pin #25 which happen to be Light Blue/back wire pin #3 on the APPS.

STOP! Don't measure your APPS voltage at the PCM this is WRONG!

Measure the APPS voltage at the APPS like Timbo does to if your going for better measure it at the ECM. By the time you measure the voltage at the PCM there might be a minor voltage loss so the voltage at the ECM will be high so hence most people complain about high idle, and other issues!

Problem #3 - How to adjust the APPS sensor?

There is no need to yank the sensor apart and mess with the 2 torx screw on the back you can obtain all the adjustment you want in the set screw on the bellcrank. But once again don't adjust for the voltage marked on the label... Make sure to flick the throttle bellcrank to WOT ans let it snap back to idle a few times and check you voltage again if the voltage is changing constantly the APPS sensor is wore out and no amount of adjusting is going to fix this problem.

STOP! Don't bother messing with the 2 torx screw just adjust the set screw on the bellcrank.