- Replies 37

- Views 8k

- Created

- Last Reply

Top Posters In This Topic

-

hex0rz 10 posts

-

Mopar1973Man 9 posts

-

dripley 8 posts

-

Haggar 4 posts

Most Popular Posts

-

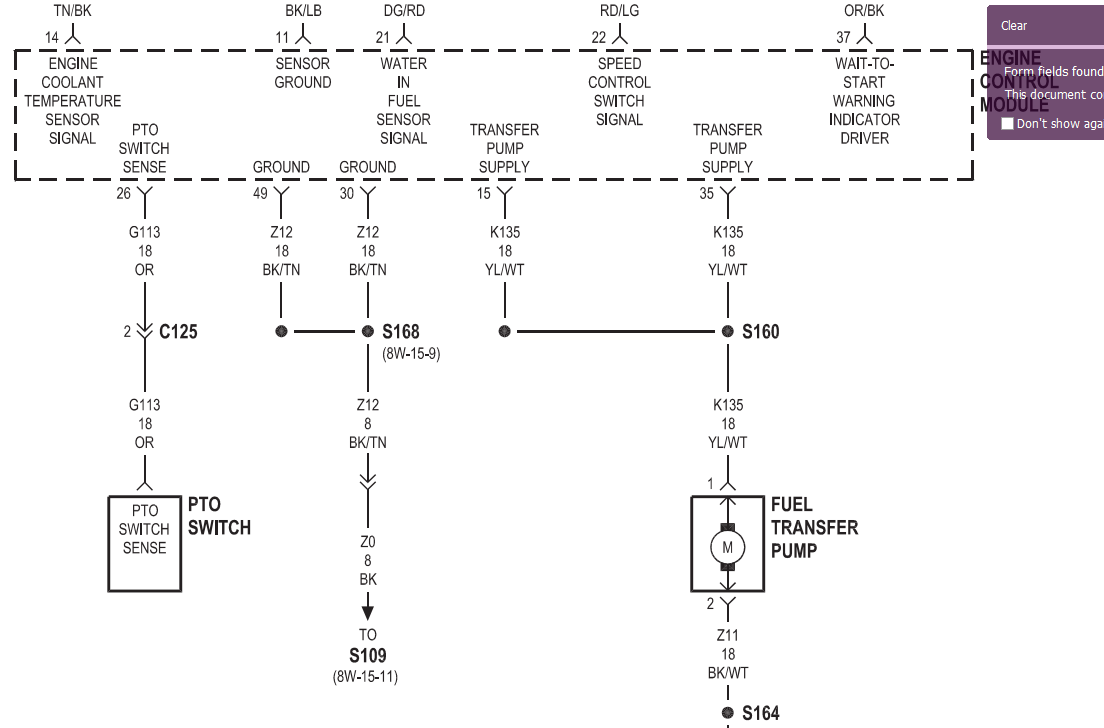

There should be battery voltage at both sides of the fuse and terminal #30 of the relay. ECM voltage at terminal #86 when ignition switch is first turned on (5sec) and when starter motor is engaged

-

The schematic is fantastic reference. NOTE - you can pull the relay from the Relay block (assuming it is plugged into a relay block) and put a jumper wire from 87 to 30 - and see if the l

-

hex, Chicken man is suggesting you check what is really happening at the ECM, not right at the plug where the pump plugs in. How are you checking it? Terminal 1 to bod

With the recent snow storm I was pummeled with, I had to utilize the truck today to get to work. Unfortunately, the lift pump wasn't giving me a pre start prime. Even cranked over and running, the lift pump is still not giving pressure.

I checked the fuse, it's good. I swapped the relay out with a different one. Nothing. I checked voltage at fuse and got nothing.

Any ideas? Pump dead? Some other electrical issue?