APPS sensor adjustment and reset difficulties.

- Replies 47

- Views 13.5k

- Created

- Last Reply

Top Posters In This Topic

-

Zach B 18 posts

-

Mopar1973Man 9 posts

-

IBMobile 6 posts

-

Great work! 3 posts

Most Popular Posts

-

Here is another link. This one is W-T's version. I like his - he uses bigger words. - John

-

EEPROM and flash memory has a life expectancy in these ECMs @Auto Computer Specialist may be able to assist you.

-

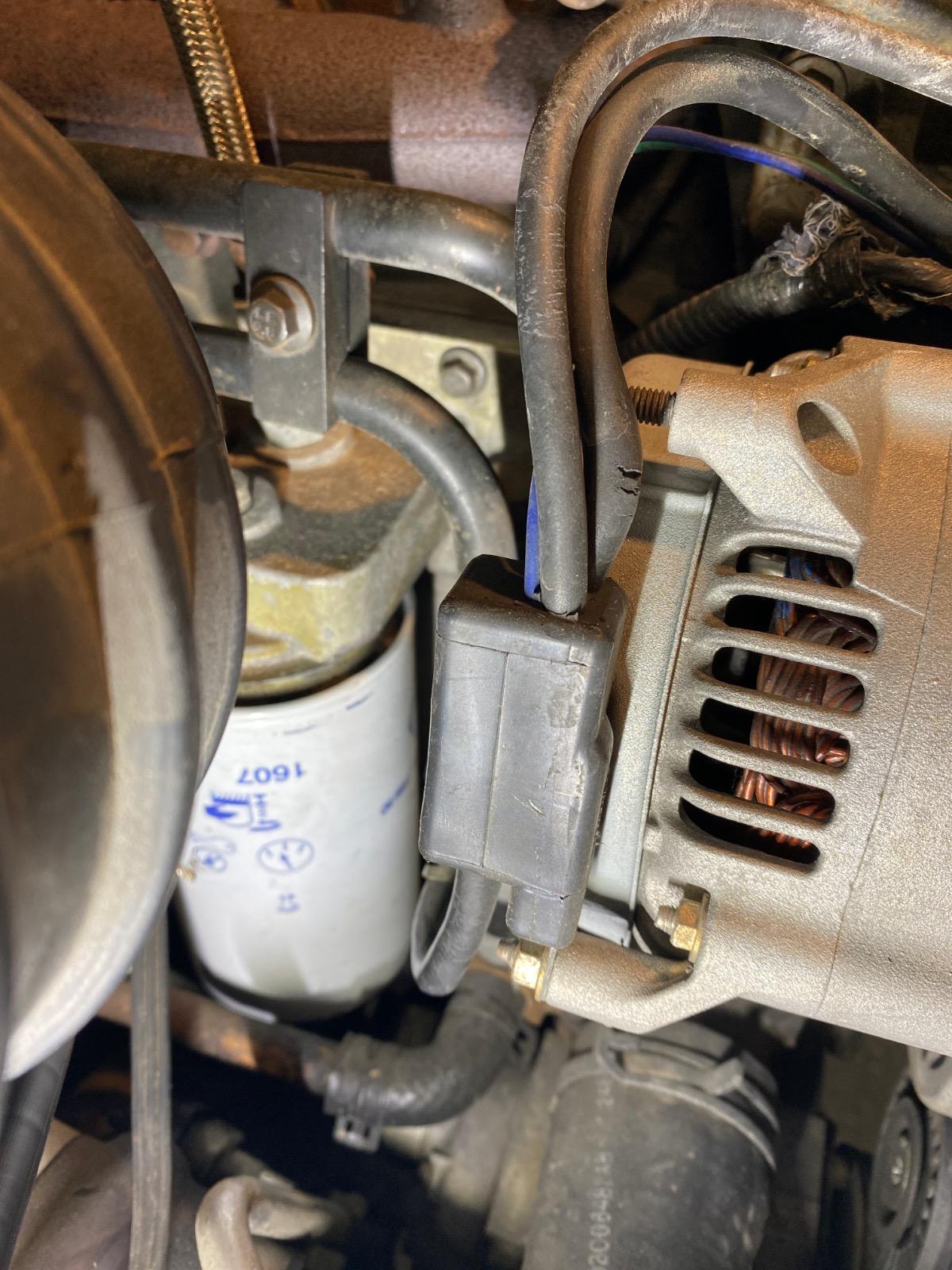

Yup I would send the ECM off to @Auto Computer Specialist and let them fix the ECM. Then I would suggest pulling you alternator have it bench tested for AC ripple. Then if you replace the alternator m

Hello all, just joined the page so please forgive me if I don't do this right.

I have a 98 2500 24v auto, and ever since I've owned the truck I've been having this issue but just never attempted to do anything about it until now. I've just rebuilt my transmission to hold 550hp, am looking to add a tuner but I know I should fix this before I try to add more power. I have read the forum here about adjusting the apps and numerous other forums and cannot find anything to specifically relate to my issue.

To start, my issue is that when I plug in my OBD scanner, my APPS sensor was reading 8.6% at idle and 71.3% at wide open throttle. So, after doing some reading, I attempted a reset. I unhooked the batteries, let the truck sit for about an hour with the key on, and then turned key off, hooked batteries up and continued with the reset process. I have done this multiple times and it seems to correct the readings on my scanner to 0% at idle and 100% at WOT for about one day, then it resets back to the 8.6% and 71.3%. I am pretty positive my OBD2 scanner is reading correctly, I plugged it into my friends truck whose is identical other than his being the 2000, and his read 0% at idle and 99% at WOT. His is also bone stock but appears to have much more power than mine.

Next, I tried adjusting the apps sensor using the method Mopar Man posted here in the forum. I am pretty positive my APPS sensor is stock. My idle voltage was .49v, and the back of my apps stated the voltage should be below .569v so I adjusted the apps to .54v at idle (note, I did not loosen the apps screws and rotate it, I used adjustment screws like what was recommended). I then adjusted the WOT voltage. It was reading 3.63v, and while I couldn't find an exact voltage anywhere, I found a YouTube video Mopar Man linked to the adjustment forum that said it should read around 3.8v, so I adjusted it to 3.8v. Also, I checked to be sure that the apps did not have any voltage spikes or drops throughout the travel, which it did not. It was a nice smooth climb from idle to WOT. Now, after the adjustment was completed, I checked my APPS reading on my scanner and it's now showing that my idle percentage is 10.2% and my WOT is 74.3%. I've tried resetting it a few times and continues to default back to the 10.2% and 74.3%.

I'm stumped. I've done all the research I can to try to figure this out without creating another post because I know there's thousands of them out there, but I cannot find anything that relates to my issue. Do I need to just replace my apps sensor or is something else wrong? Any ideas or suggestions would be greatly appreciated.