- Replies 74

- Views 9.6k

- Created

- Last Reply

Top Posters In This Topic

-

TFaoro 19 posts

TFaoro 19 posts -

rancherman 11 posts

rancherman 11 posts -

Wild and Free 10 posts

Wild and Free 10 posts -

Mopar1973Man 8 posts

Mopar1973Man 8 posts

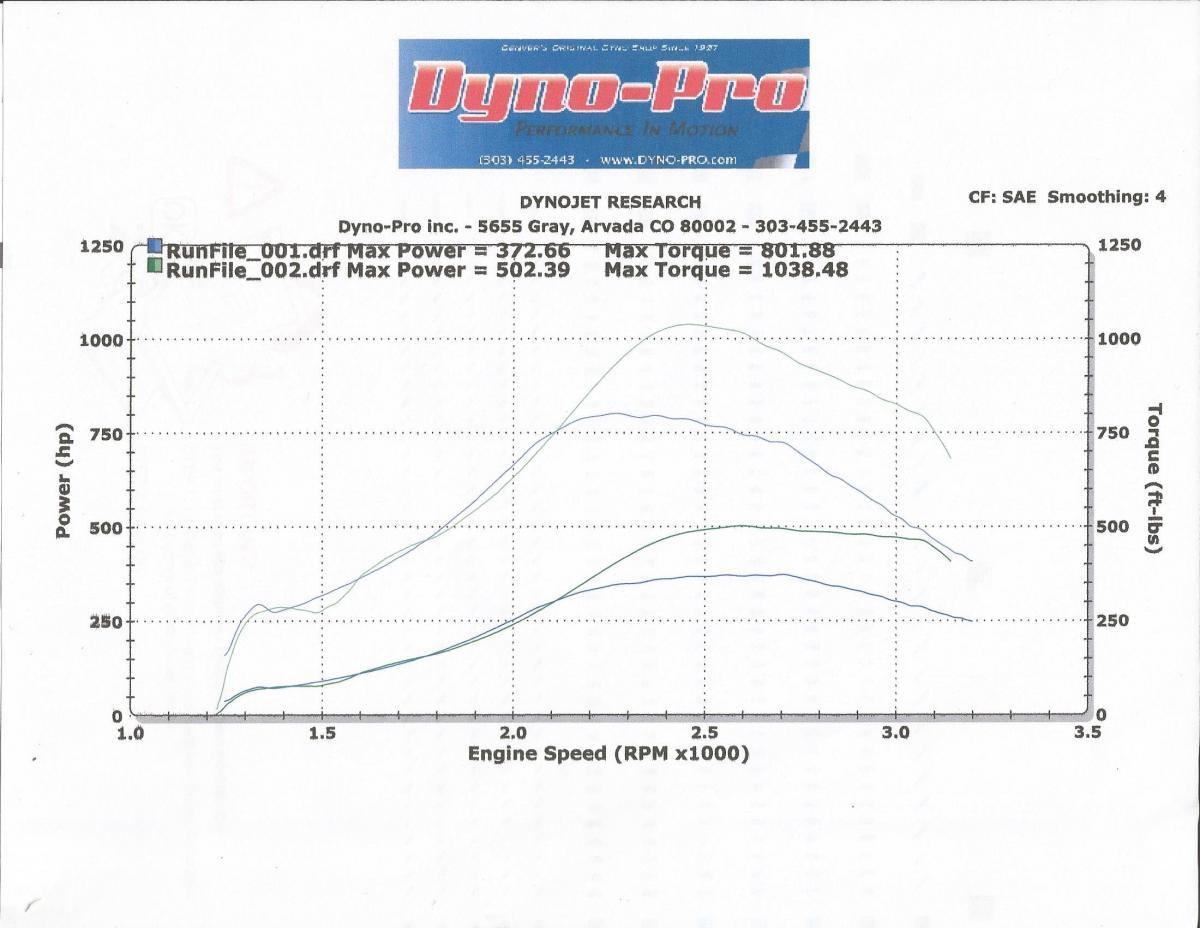

I should be hopping on the dyno this weekend (As long as my brother doesn't blow up his 05 first)

Couple of questions: Anyone have any thoughts on which level for a smarty only run? Any thoughts on which level for a smarty + TST run?

And for the fun part! Guessing

Give your guess for: Smarty only and smarty + TST My sig is up to date!