Everything posted by Mopar1973Man

-

Red Head Steering Box

Little secret Blue Top supplies parts to Redhead... Better to go to the actual source...

-

Cutting Out Under Hard Acceleration/Above 68 MPH+ 2500 4x4 47re

Yup. Best thing is to get a tuner so you have the boost fooler, fuel management and the timing management. The only tuner today on the market that can do all this and give 180 HP gains is Quadzilla. You could do a Smarty Touch (60 HP) but it will cost you triple the price (about $1,800 to be able to make your own tunes) and 2/3 less power.

-

Red Head Steering Box

Blue Top I'm running is a upgrade since I went down from the 265's to the 245's I upgraded to the "Quick Ratio" box so she is snappy with steering. I've got a few final adjustments to make on my steering center the steering wheel and take just a tick out of the sector adjustment on the gears. She will be a rocketship on rails at that point. I've got a 2005 in the yard I'll be pulling the steering box as well and shipping to Ryan @Blue-Top Steering which happens to be one of our vendors here.

-

Red Head Steering Box

Better yet im running Blue Top Steering.

-

Pcm voltage issues

Tach signal i don't think is frequency but digital info. Tach signal is typically sent by CANBus in a digital signal so as long as there is no P1698, P1694, or code for crank and cam sensors (if applicable). You PCM should have tach signal. If you have a live data tool you can confirm what the dash shows. Like Quadzilla rides on the ECM CANBus so you can't see any PCM info. Just a heads up.

-

Zero Boost Tune

Well I finally got it. I've tested this tune and really surprised you can hold the turbo at ZERO boost even at 65 to 70 MPH. After 150 miles in bit over a 1/8 of tank used. This includes climbing two 7% grades. Really cool to see the boost hang at zero but put it against a grade it barely 5 to 10 PSI boost. EGTs are bit higher climbing so I would not suggest towing or racing with this tune. What makes this tune so neat is the 5 to 14 PSI is flat stock tune 100% no boosted fuel on CANBus. At 15 PSI up it gains at a +5 step so it gains power quickly. Now if you toss in wiretap you better be ready... It pulls extremely strong in the upper boost range. Return to cruise state it hover about 19.5° BTDC at 2k RPM at ZERO boost. So this tune you can have your cake and eat it too... I'll release this tune in the morning...

-

Is there a "recirc" for heat?

Lowest mine drops at idle is 188°F coolant. If falling lower then your thermostat possibly stick open a bit longhand drawing too much cool coolant in.

-

First road trip in my 2nd Gen

I've still got people out here that have lived generations with out power. Better bring a generator and long cord and can of gas. Like myself be self-contained. You can get the high idle kit. It will help a bunch. Even Quad high idle is better than nothing.

-

Adrenaline High Idle Not Working

Problem my fuel map might work. But my timing is built around my injectors. Ill tell a bit more of my tune after bit more testing.

-

Adrenaline High Idle Not Working

Nothing stop members from creating their own write up of what they learned. This is why when you make a new article automatically the forum thread is started so you can discuss about your article and improve it with feedback from the members.

-

Adrenaline High Idle Not Working

Warm up mode when ON. Warm up mode will force level 0. You'll notice the power bar is GREEN. This means its locked for warm up mode. So the fuel map the 0 PSI position is the power you'll be given. Like my 0 PSI is a 80% fuel. So this is the max till you reach warm up temp. I'm set for 140°F for warm up allowing the timing to step up. Once it reaches your set temp the it will return to your previous set power level. Like me for most stuff I was running level 2. Now I might of figure out a way to have level 2 at level 3 but still playing with my map to see what I produced. I focusing on my MPG tune to get the absolute most from that tune but still allow for added power in the tune for passing with out having to level up and down. I'll release my tune here soon. So far it got enough to spin the tires in level 2 now.

-

First road trip in my 2nd Gen

Nothing really... Winter temps here can range (+32°F to -40°F). Most here know I drove my Mom to dialysis for over 5 years and every single morning I just fired up and drove. Subzero weather is nothing. Still ran 15w-40 engine oils (petroleum). I normally let the engine warm to about 100-140°F before rolling. Even this winter the lowest my oil temp has gone at -10°F was barely 158° to 162°F. Day in day out I live in super cold area of Idaho. I do not use any anti-gel fuel products, I do not use any cetane booster. Then only thing I do is turn the key and wait for the light and start. I don't even plug it in till its below 0*F as Cummins suggest. I typically just fire up the 3 CYL high idle and the exhaust brake and have heat in less than 10 minutes and the ice is gone from the windows. This way I'm not hunting for power to block heater because lot of my jobs I end up in the back country away from power at times. 426k miles all I do is turn the key, wait for the WAIT TO START go off and start. No added cetane or anti gels. To this day I've never had a fuel gel issues. Just a couple of days ago.

-

Is there a "recirc" for heat?

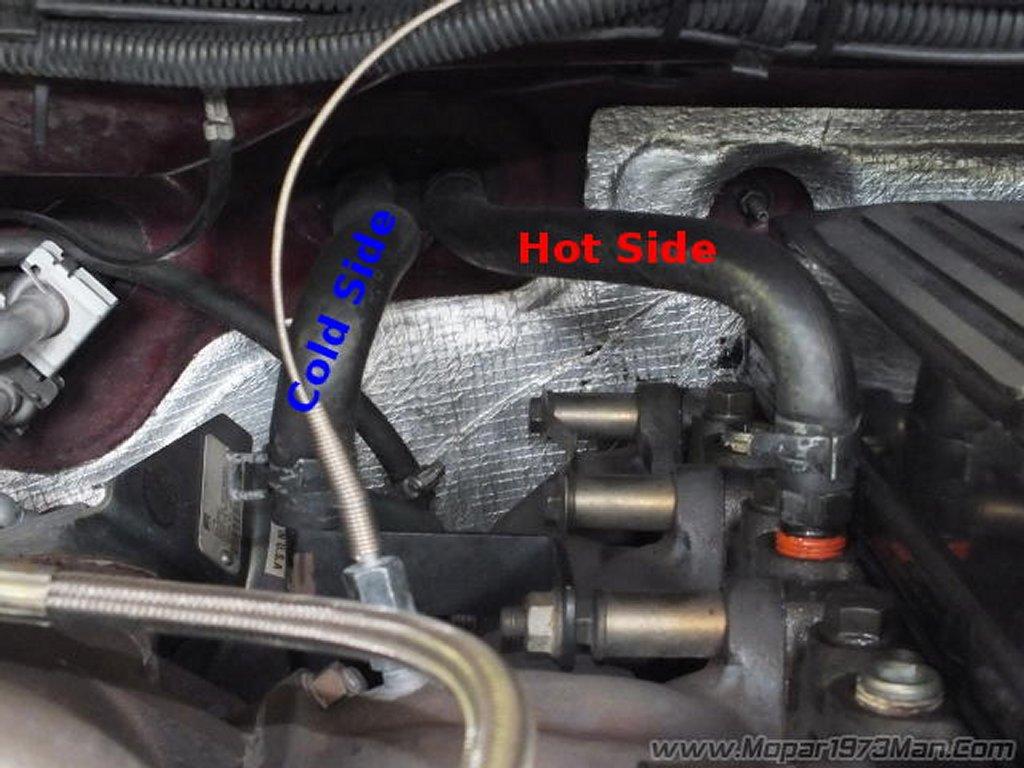

Simple fix. It will take a bit of work. I'm going to bet your heater core is partial plugged up. So the coolant flow is poor through the heater core. If the heater core is working correctly and coolant is hot (190° to 198°F) then you should be able to feel coolant temp change between heater hoses. Now if the heater core is partial of plugged up mostly the hose will feel the same temperature meaning there was no air to coolant exchange. Like On my truck the hot side is HOT and you can hold the hose for very long. The cold side is warm but MUCH cooler than the hot side. This shows I have excellent heat exchange and getting a majority of the heat from the heater core. Second problem is plug evaporator it will slow the air down greatly. Out here I deal with a lot of rancher that use there truck to feed cows and live stock so hay and pine needles are really common debris I find in the evaporator. This one all I did was change the heater core because the hoses were the same temp (poor coolant flow). Then power washed the evaporator and now the owner today complains that the heater will fry here out. Heck NAPA heater core is cheap and you could have heat like do in a mere day... https://www.napaonline.com/en/p/NRZNH9010015?partTypeName=Heater+Core&keywordInput=heater+core

-

pulling to left while accelerating

Yeah commonly people have a 1 to 2 inch leveling kit and it causes the axle to be pushed down more so that tend to make the caster more neutral so the wondering is more pronounced. I've got a 2005 sitting here with a 3 inch kit and wonders bad. Then I've got my 2006 Dodge with 2 inch leveling kit it wonders as well. Both have little to zero caster and over sized tires. Makes it even worse. But hey this what I see come and go through my shop. Just remember if you use a lift kit you not lifting off the axle but pushing the axle down if the lift is too much then it can pull the axle to the driver side because the track bar is now too short. (Thrust angle error) Then with the downward travel the axle rotates forward and makes the caster neutral. Hence the steering issue most lifted truck deal with. (caster angle error)

-

Dash wiring harness compatibility

ECM and PCM are both fried. Start with sending them both out for repair. Then pull the entire harness out and send it to Auto Computer Specialist and they do full wiring harness repairs. The external regulator is a sign you fried the blue wire with a short fried the PCM voltage regulator. I do have a fix to prevent that. Then as for the ECM you need to do a new alternator and the W-T ground wire mod. This will protect the ECM from frying. You WTS light issues stems from excessive AC noise and burned the ECM up. So all you did to remove the VP44 because of electronics you still got shot in the foot. I still recommend to ditch the P-pump and return to a VP44 becuase they have way better street manners. Way better diagnostics and power to be made vs a static timed pump. Still in all you nedd ECM, PCM and the wiring fixed. All came be done through Auto Computer Specialist. The VP44 world we can make some serious power with the Quadzilla and VP44 pumps. No smoke and all pure power. I'm roughly 500 HP and leaving 3rd gear with stock fuel (Quad Timing only Level 2) I can break the tires loose in the 3rd on dry pavement. Still little low in MPG but 18 to 19 MPG is shabby. Got a new idea for a new fuel map. When your tuning from your phone vs a tool box... Something a p-pump cant do without HOUR of tool time and setting plunger lift but still no dynamic timing. I typically cruise at 19° t o 21° at 2,000 RPM.

-

Adrenaline High Idle Not Working

Warm up mode needs to be ON as well as the high idle delay time ON. I just did a demo here yesterday of that feature and it work like normal. I can switch to level 0 and it runs forever until throttle is seen or movement.

-

Hydroboost problems

Ahhh... yeah that would do it.

-

Changed turbo and exhaust manifold - now I have white smoke under acceleration

Yup drop the Quad in and im going and doing some new testing myself more for MPG purpose. I've got a different idea for the fuel map.

-

pulling to left while accelerating

Or you have a lift kit without adjustable track bar will do the same thing.

-

Hydroboost problems

Yeah I had the check valve fall out on me while doing a customers rig. I at least seen it fall was able to see where it went. His the came apart super easy.

-

Moving to almost the great white north.

Damn! That looks COLD! (Brrrr!)

-

Changed turbo and exhaust manifold - now I have white smoke under acceleration

Gotta ask how did you tighten the injectors? Crossover tubes first then the hold downs on top of the injectors. You could have a crossover tube not sealing.

-

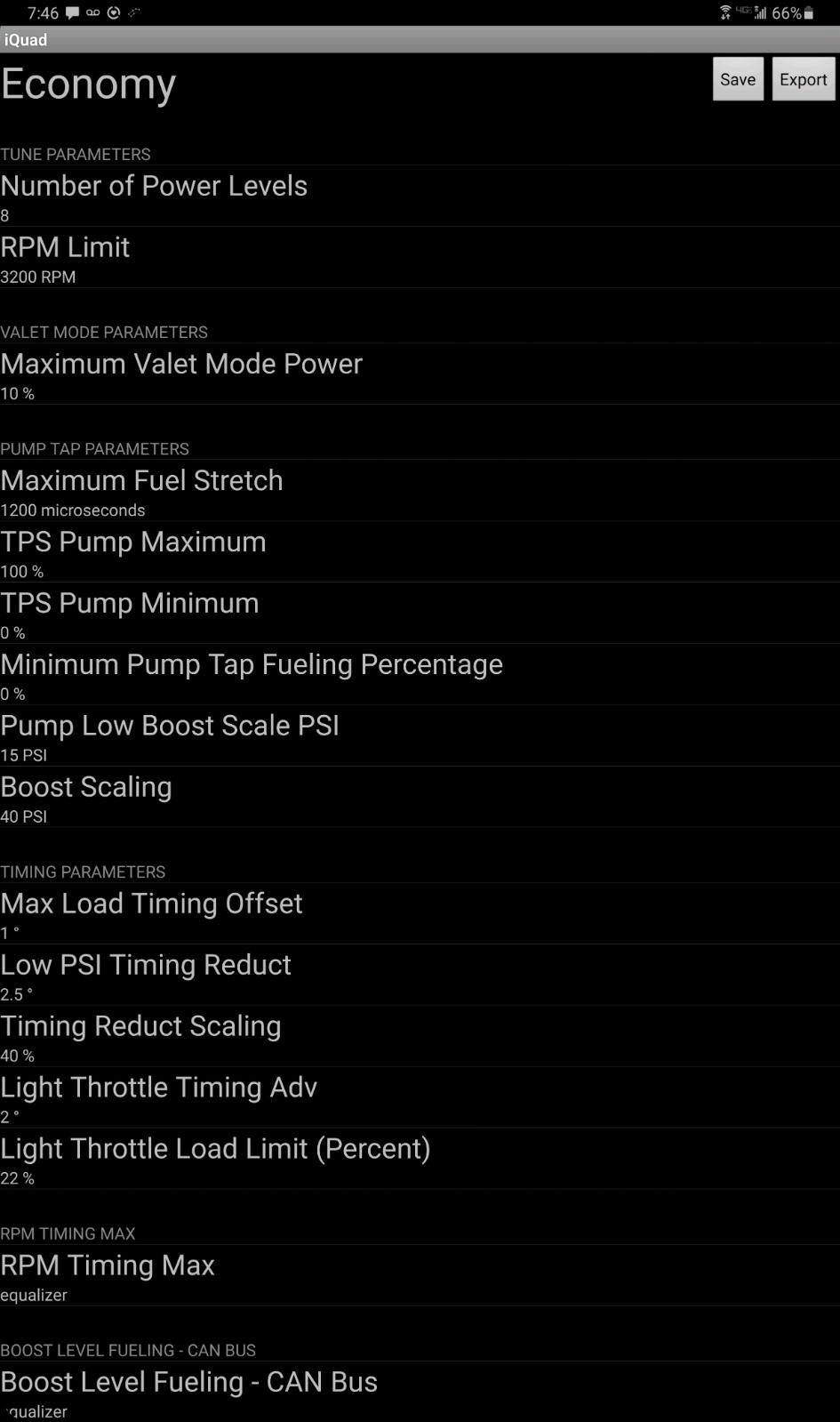

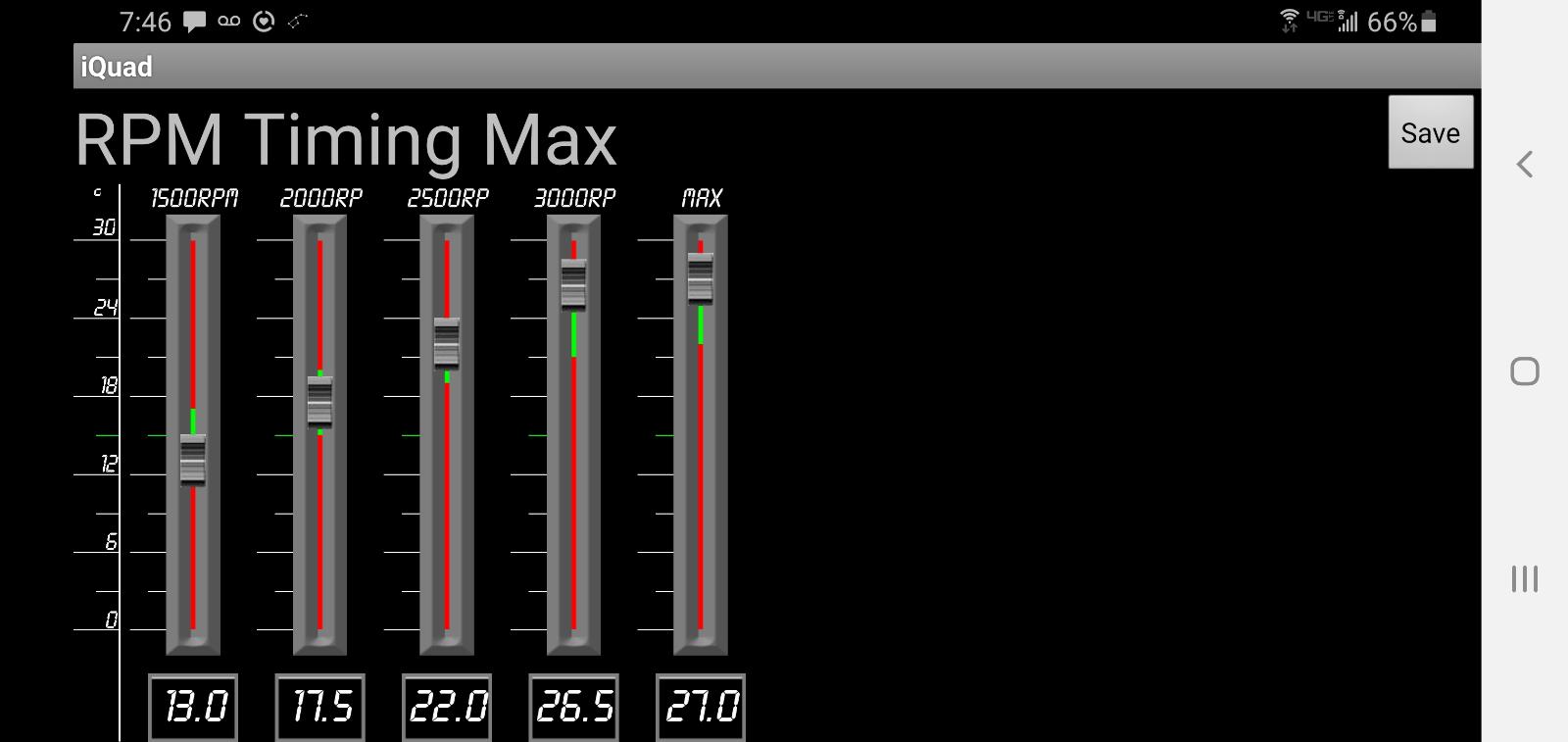

Quadzilla Tuning - From a newbies point of view

Skip the DEFAULT tune it won't fit. If your true stock maybe it would work OK. You upgrade injectors, turbo, and few other items so now the default tune would work but not optimally. Personally since most of the performance is in the timing I would start there. Run level 2 without CANBus fuel or Wiretap then you can build the the defuel curve to control launching smoke. I'm 7 x 0.010 and start my fuel curve at 80% for most everything. Like economy tune doesn't reach stock 100% level till 14 PSI. Then at the 30+ PSI position I'm only 123% over. (Beside the point). You need to focus and get the timing good for just your stock fuel. Right now I'm 13.0, 17.5, 22.0, 26,5 Max 27.0 That is max timing. I would twist this down to a +4 step. 13, 17, 21, 25. This will be better fit for timing. It will have good launching power. You light throttle timing advance would be +2 to above so 17 +2 will make 19 degrees for cruise timing. Low pressure timing reduct 2.5 with the scaling at 40%. Currently I did it yesterday on dry pavement pulled up 3rd gear and rolled into the power and rear tires let go instantly. (full wire tap - I know the timing for my setup is wicked). Max Load Timing Offset is 1 degree. Fuel curve you can build at any time dear but for you in "Commie Fornia" you better start on level 2 and get timing and stock fuel looking good then work up. Suggestion for staying clean. Measure your normal cruise boost level, then watch your rolling hills throttle, you want your wire tap above that. Like my normal cruise is like 5 PSI. Then mild grades and rolling hills I can hit 10 to 15 PSI. After 15 PSI the wire tap starts. The give great stability to running in snow as well without the sudden shock of the wire tap as when set lower also when it comes on the turbo is spooled so it just cleanly continues to eat while creating new smoke off the tires. Two things to watch for shuddering is a sign of over advanced timing. When it sound flat and quiet your retarded in timing too far. When making changes its best to run a full tank through and see how it impacts the MPG number which is the best method to verifying if your gaining or losing performance to fuel. This is a +4.5 degree step might be too wide for your setup. Again start with 13 degrees and step up only +4.0. This should fit you well.

-

WOT upon starting

Basically the ECM is shot and will require to be pull and tested and repaired. The articles above are to prevent future failures or testing for conditions that might cause a failure. Sine your ECM has failed your going to need to repair it first but you not going to want to install a ECM to possible bad condition that might cause it to fail again in short time. Basically in a nutshell AC noise is really hard on electronics the AC pulses force apon thing like digital chips and other part that ain the family of diodes and transistors will take damage fairly quick. When the polarity swap back and forth this creates heat on these parts and hence the failure.

-

Crisis Proportion or Covid Craziness.......

That's why I love being here in the forest of Idaho less BS. Less crowds. Less problems. Most city folk can't handle the life out here. I've got my weapons, food, self contained power and water. Do not require city services at all. Like this morning its snowing in McCall and something happened and the power went out briefly. The inverter kicked in instantly and still here at the computer. Even got fuel (gasoline and diesel) on the property nothing is going to slow me down much. I don't expect much to happen out here but watching the bigger cities like Los Angeles, CA fall apart...