Everything posted by Mopar1973Man

-

Nv 4500 bell housing torque specs.

I normally just brake clean the spline shaft and leave the grease off the spline shaft. Yes it will splatter grease int the clutch. Throw-out bearings typically already have enough grease in the inner collar. Just make sure to clean it up after installing. Even fuel leaks around 4, 5, 6 can drip fuel into the clutch area.

-

Dimmer switch, back lights not coming on

- Multiple LP failures now hard starting when hot

Cranking pressute between 7 to 12 PSI will start every time. Above this will cause hard starting because it over advances timing making its tough to start.- New VP44 - Engine requires excessive cranking when hot

Stock pumps tend to create cavitation when the lift pump is dead headed.- Multiple LP failures now hard starting when hot

Hey, @dieselautopower you took away all my fun...- Multiple LP failures now hard starting when hot

I just sold a DAP VP44 injection pump for $1,100 here in the valley plus the labor. Nice to have my vendors @dieselautopower and my sale tax permit I get these pumps at cost and make a bit of profit. I can't tell you my price because I'd have to kill ya when you hear my price.- Multiple LP failures now hard starting when hot

Cranking pressure should be 7 to 12 PSI bouncing. If its too high it will cause hard starts.- Normal Load % for Basically Stock Truck?

Mine is a old 2G AirDog pump originally which lasted 250k miles and about 13 years. I got the short bed bracket so my AirDog is tucked right up behind the transfer case. Out of the debris path of the tires, warmer location for the fuel system and I've ran all the way to -40*F so far and no issues with gelling. I purchased it from another vendor in 2006.- Normal Load % for Basically Stock Truck?

No gains... I can clear the tank all the the way down to EMPTY mark no problem. There is less than 1/16" a inch between the bottom of my tank and the straw when the tank is empty. Then when I fill the tank with diesel is roughly 227 pounds and deflect the bottom at least another 1/4" inch. Never had pressure problems, no wild swing 1/4 tank issues. Cool fuel temps at the VP44.- Normal Load % for Basically Stock Truck?

- New VP44 - Engine requires excessive cranking when hot

Exactly. This is proper ECM control of the lift pump it switches the 12V on and off at a about 50% duty cycle to reduce fuel pressure. This is so the proper cycle of the lift pump and should bounce the pressure at 7 to 12 PSI.- Normal Load % for Basically Stock Truck?

You remove the filler neck and filler hose. The LARGER hose you cut and slip in the return fitting. The smaller vent hose is left alone.- Side load intake Manifold

Like myself... 7 x 0.010 DAP injectors popped at 320 bar. HX35/40 Hybrid turbo (60/60/12) Quadzilla Adrenaline Smarty/Edge stack is bad deal for sure. Stacking any tuner is a bad deal. First off neither tuner has good timing control. Then you made a light switch out of the throttle. It can be 100% fuel by 30% throttle position. Too much fuel and no enough timing control. Trust me... I was a ex-Edge Comp runner and managed to make a heck of a high MPG number of 27.2 MPG. The problem is you have to drive below 60 MPH to keep the high timing on Edge products. Then with bigger injectors the timing is too retard and now it creates a lot of EGT's. Where with the Quadzilla I can up the timing to meet the injectors needs.- Normal Load % for Basically Stock Truck?

During the install you put the return tee in the filler hose not the vent hose. Just hose clamps in. Exactly why... The fuel coming out of the head is heated to near coolant temps. Then you drop back in a small cup of the sender and now pump it right back to the VP44. Never had a heat issue since my AirDog install. Back with the old school stock pump I use to turn the filters black from the heated fuel asphaltenes (if I correct in spelling). No longer happens since my fuel temp remains low typically same as the intake temp. Still not having 1/4 tank issues either.- Side load intake Manifold

I towed my 31 foot RV all the way to Mohave Valley AZ never had hsat issue with the engine. Lot of grades held my EGTs at 1,000 to 1,100°F but never got hot coolant wise. My biggest problem was transmission temp on the long grades. It was the radiant heat from the exhaust heating the transmission. I built a simple heat shield and drop 40°F on average.- Considering buying a deleted 6.7. What do I need to know?

I will no longer will suggest deletes. After seeing how dealers will not sell deleted truck or even take them in. Too much trouble to delete then gave laws change and get caught with a truck missing all the smog stuff.- Normal Load % for Basically Stock Truck?

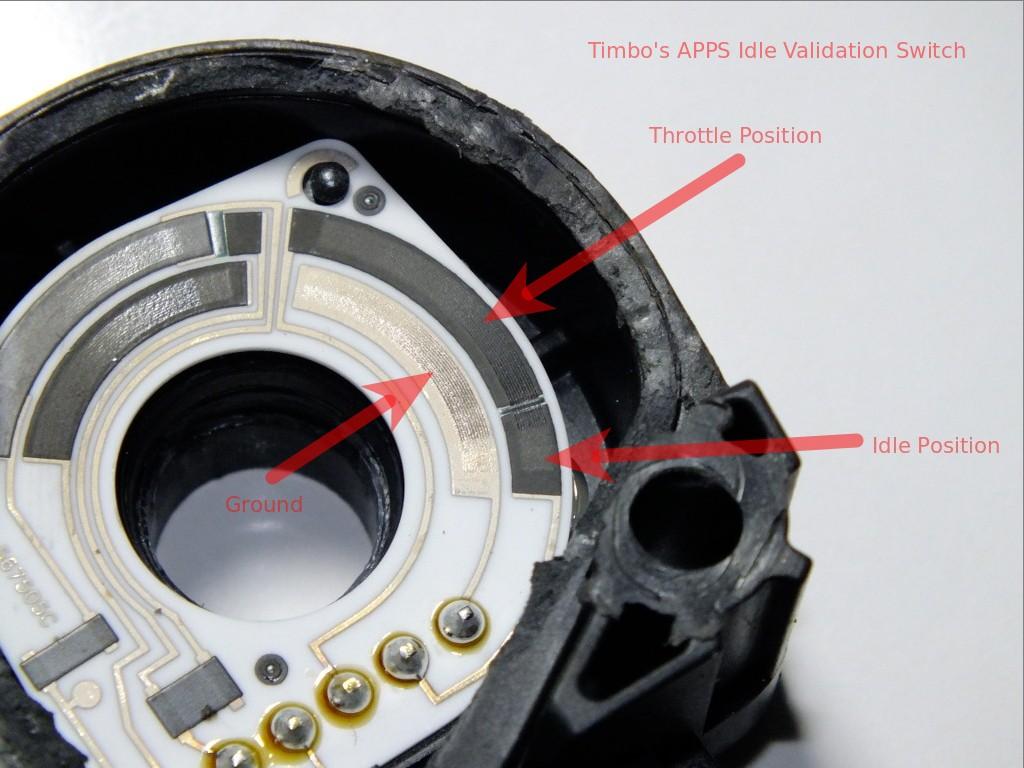

Mine is slightly different. AirDog return is not in the basket. Mine is in the tank filler tube and my pickup is not in the basket either. It in the cooler part of the tank. So for those returning to the basket and the drawing from the basket is going to have the highest fuel temps. Since my returning fuel from the engine is in the basket I don't see the heat from the engine being the AirDog picks up out of the main fuel area and the AirDog return is away from the straw so I don't get all the foamy fuel either.- New Error: P0122 APPS Sensor Signal Voltage Too Low - Where to begin?

- I Want Easy Brake Bleed.....

Not needed being the weight of the fluid cannot be pulled back up out of the jar. Hence why the mayo jar works so good and doesn't need a helper for the screw and why it can be done solo. No need for pumps, or expensive check valves or special caps for the reservoir.- Economy Car Or Diesel Truck to go shopping...

Um... Hyundai Elantra is not 4 down towing ready. I'm not buying a tow dolly just for that. Ugh...- Tps/intermithttps://mopar1973man.com/topic/17826-tpsintermittent-dead-pedal/tent dead pedal

Do the W-T ground wire mod... That will fix the ground wire problem.- Economy Car Or Diesel Truck to go shopping...

@Wet Vette finally got it figured out shopping trips to Lewiston, ID or Ontario, OR are now done with the truck. We has a second go around trying to do some shopping for a camping trip and loaded up with both grandkids (Parker and Kayden) and started to run out of room in her little Hyundai. It was stuffed. Now she wants to take the truck because it will hold the shopping easier than stuffing the little car.- 3rd or 4th gen fuel pump in 2nd gen

Typically it was only the 12V with overflow problems because the bolt was soft steel and the ball would beat the seat out. 24V overflow valves typically don't fail. I know you have the belt driven lift pump. Heck I just did a 16 hour day, ran my truck over 414 miles doing a injection pump job in Anatone, WA. The entire day was cool out and truck was kept running most of the day with driving. I had temps ranging from about 65*F to a high of 80*F in Lewiston. Climbing 3 different grades and a few good twisting roads. I even had to go back to Lewiston for a special tool to pull injectors and back to Anatone, WA in the back country. Fuel temp never over 120*F the entire day, 414 miles, 5am to 9pm... Long day...- I Want Easy Brake Bleed.....

Mayo jar hooked to the bleed and pump straight in the jar. I change brake fluid every 30k miles. Yes I full stroke of the pedal and no problems after 418k miles. I know most say don't do this. Like my 2002 has a aluminum master cylinder and being I make sure to change the fluid before its moisture loaded and rotting the seals. So this is the main reason I don't work about full stroke of the brake pedal. Full that gets this dark is loaded with moisture hence why the brake fluid start weakening the seals in the master, wheel cylinders, calipers and even hoses. Again 418k miles and no issues even with brake hoses.- Side load intake Manifold

Shaving off the manifold is something you would do for a super high HP engine there is no gains to that for a daily driver. I'm running bigger injectors than you and just a slightly smaller turbo but still all stock air system and most likely have lower EGT's than most here. - Multiple LP failures now hard starting when hot