Everything posted by Mopar1973Man

-

New Life and New Body with issues...

Even like today I got up and hauled out to the shop to see if I could finish the injector repair. Hit my wall by breaking off a terminal of the injector. Ok. Having been out of service for 1 full year, I'm allowed to make mistakes. Oh well, I'll still get it fixed just delayed repairing one injector. Yesterday I got the injectors out and needed a can of brake clean and scotch brite pads. I got to McCall wearing my split white and black wig and basic black makeup. This older lady in her 60s looked me over and started to chat about my appearance. She enjoyed that I had the spirit to do as I please and be colorful. I went into the store and came back out and she was still there and she started a new conversation with me again. It's to the point I'm getting more people telling me to keep going and don't stop. I've had several people who come up to me to give me a hug from different stores and places. It is very commonplace when I'm dressed as Titanium.

-

2006 Dodge Ram 3500 - Thor Project

Update... So i pulled all 6 injectors doubled checked the fitting of all parts and made sure all parts were of good condition. Now brake cleaned all parts and mating surfaces to bet sure everything was clean and job is done absolutely right. Now during reassembly I had the terminal post snap off the #1 injector and I'm going to have to send this one out to be serviced and repaired. Sadly I got a delay to fix one injector and already called @dieselautopower and talked to Mitchell and got everything ready to ship out tomorrow. Temporary pause button on Thor for the moment...

-

2006 Dodge Ram 3500 - Thor Project

Injector inspection. I managed to get all 6 injectors removed. I'm going to town for a scotchbrite pad and brake cleaner.

-

2006 Dodge Ram 3500 - Thor Project

-

Bad CTM?

Steering wheel radio controls? I'm wondering if the clock spring is making a voltage malfunction in the CTM. Short?

-

Bad CTM?

I would start with the key fobs first check batteries and check to see if creating signal. CTM I've not heard of a failure really. Might check wires see if anything is damaged (mice).

-

Help with Quadzilla 3 cylinder/6 cylinder box

Tried calling you this morning but went to voice mail.

-

Help with Quadzilla 3 cylinder/6 cylinder box

Hey could you give me a shout in the morning. 208 315 1470

-

New Life and New Body with issues...

Well I'm coming back. I'll admit I'm not able to do a lot of jobs. Anything in the heavy lift is over. Currently have Thor stuffed in the house garage and getting ready to go back over the injectors again. Now Thor my 2006 Common rail is my pet project. Like a Phoenix rising from the ashes the new version of me will be going public. Sadly no more wrench time for me. I'll still play with my own rigs. My problem is I've got to consider my stoma and kidneys. So I'll continue my education of the Cummins line. As for my medical issues I'm clean of cancer nearly 6 months. Check up coming. I'm stuck with Stage 3 Cronic Kidney disease this is due to my kidneys being choked by the cancer. The website I'm going to upgrade software and there is a lot of new features coming. Stay tuned in. There is a feature to have live chats again and when the chat ends it will convert the chat unto a forum thread auto-magically. One of many.

-

Help with Quadzilla 3 cylinder/6 cylinder box

Well i guess I better find some time and install my high idle switch back in Beast. I got the first unit built and been laid up with my cancer. Now I'm getting back to attempting to be active. Still kind of weak.

-

Help with Quadzilla 3 cylinder/6 cylinder box

There was a version that was built with all the wires soldered to the back of the switch and had a high failure rate. This was due to the fact the switch requires a printed circuit board to make it strong enough not to pull the contacts out of the rotary switch. There was no way to repair this version. This was all ditch and superseded with my previous version with a printed circuit board. Fast forward... I teamed up with Quadzilla to get production rolling again. https://quadzillapower.com/High-Idle

-

Replace or Rebuild?

Just consider this con... Every 100k miles on common rail engines you must replace 3200 dollars of injectors. Then like Thor is my problem child and having issues holding prime long. Grid heater light popping on. Then another con is common rail engine will not last 1 million miles. Typical life locally is 250k to 350k miles the engine is wasted and blowing oil everywhere. Great example 220k miles and needs over $8000 of engine work. https://www.tiktok.com/t/ZTY7bk7sL/

-

Help with Quadzilla 3 cylinder/6 cylinder box

Connection between both IAT plugs are OPEN. Hence the value is -40°F. The ECM is going to see +5V and throw a high volt code for IAT.

-

Help with Quadzilla 3 cylinder/6 cylinder box

IAT circuit has failed.

-

2004.5 engine stopped running while driving

Your welcome.

-

Help with Quadzilla 3 cylinder/6 cylinder box

I need both IAT and ECT sensors results. ECT is showing the 123*F on the coolant for 6 cyl but I need the IAT sensor to show what mode to start. I used to have 10 gauges on my old OBDLink module. Also had horsepower and torque calculated as gauges. MPG - IAT = 143*F and ECT = Normal Sensor 6 CYL - IAT = 26*F and ECT = 123*F 3 CYL - IAT = 13*F and ECT = Normal sensor Basically IAT sets the mode. The ECT tells if the mode should cancel at 170*F of coolant or hold the mode.

-

2006 Dodge Ram 3500 - Thor Project

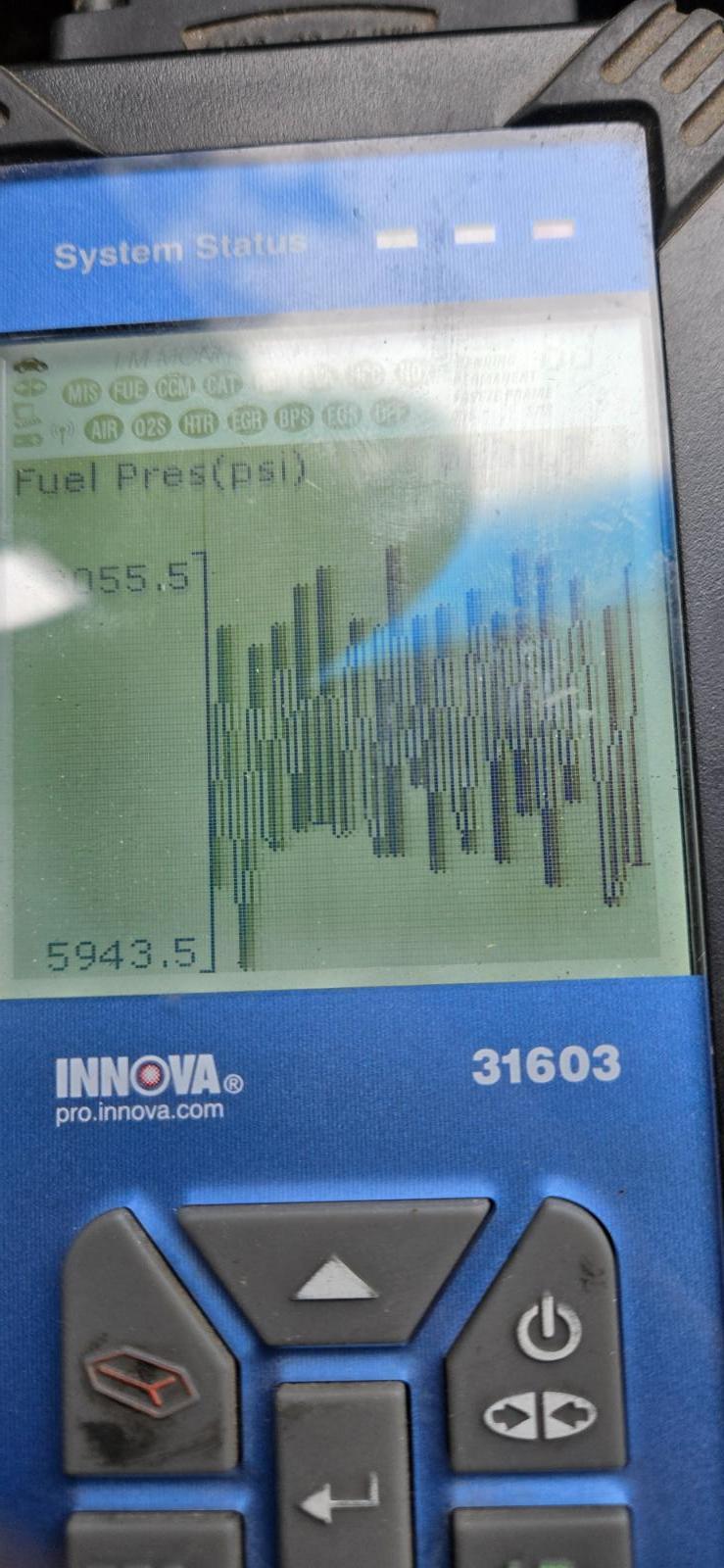

I'm pretty sure now it's a loss of prime. Somewhere in the crossover and injectors yet. I managed to get all set up a graphic display of rail pressure. The lift pump comes up fairly quickly to 14 PSI then the rail starts at 84 PSI engine off and key on. Now when lift pump hits 14 PSI quickly order the rail bounces from 84 PSI to about 1,1xx PSI continues to crank then the surge hits at 12,xxx to 13,xxx PSI and the engine starts the pressure settles at 6,xxx to 8,xxx pulsing. Changed the supply banjo seals on the CP3 and stopped a weeping leak. Then for fun pulled the fuel filter to look at filter condition and lid seal. Filter needs changing and the seal I changed from a salvaged seal. The crank time is greatly reduced but still could trip a grid heater light on only deceleration and its a 10 chime account again. The grid heater light can be reset.

-

2006 Dodge Ram 3500 - Thor Project

Ok. @Tractorman The lift pump at key on rose to 14 PSI during grid heat. Then, during cranking, the rail jumped to 17,xxx PSI and continued to be hard to start. Now, I stopped and unplugged the FCA and tried again. The lift pump again rose to 14 PSI during grid heat. Then cranking jumped to 17,xxx PSI, and I also continued to crank until it started. The only difference was the FCA disconnected rail stayed max pressure where after starting with FCA would drop back to about 7,xxx PSI roughly. Now on the run the lift pump runs right down to ZERO pressure on a WOT event heading towards 80 MPH. Rail stays pretty much at 19,xxx to barely 20,xxx PSI. Shut it off for a very short time say 1 minute and start again same thing the lift pump comes up and rail jumps up in pressure and continues to crank. Funny part is it runs great. I can spin the tires on launch from the driveway. Good power and everything. Just if the grid heater light comes back then it might limp mode the power. I would love to have the true definition of that grid heater light and what it means and what is monitored.

-

Help with Quadzilla 3 cylinder/6 cylinder box

Yes sir you can. Just key on and click the switch through the different modes and report back the values seen.

-

New Life and New Body with issues...

-

Help with Quadzilla 3 cylinder/6 cylinder box

Live data tool and look to see if the fooled temperature happens. Coolant should be 123°F (3cyl) and IAT either 26°F or 13°F for 6 cyl and 3 cyl. Engine does not need to be running.

-

2006 Dodge Ram 3500 - Thor Project

Correct no leaking fuel on the ground or externally. I'm looking at the over-pressure valve, possibly still debris or something fouling alignment of the crossover tube. Funny part last run the CP3 was pinned at 20k PSI and working hard core to feed the truck and the leak at the same time. Weird... Typically grid heater light is tripped as I change from heavy throttle to light or coasting. Then it sets the light chimes 10 times. To regain power I've got to pull over reset codes but no codes could be found. Press ERASE and the light goes out. During an erase command the engine cannot be running. It takes less than 60 seconds to erase and then the super long hard start to resume. I did this at the rest area south of Riggins, II but less than 2 miles light came on again. Light comes on more so when coolant is over 200*F. (204 to 210*F). Cold the light stays off still really hard start.

-

2006 Dodge Ram 3500 - Thor Project

I'm going to have to start from ground up. I'm not holding prime very long. Went to town and got the grid heater light twice 10 chimes. Stop at the rest area and cleared the light as was like total loss of prime in seconds now. I've got to check pressure during the hard starts which I'm sure the CP3 is dry a drill going to show zero pressure during crank.

-

2006 Dodge Ram 3500 - Thor Project

I'll check in the morning. I just had another hard start just getting it started to move back in the garage for the night. I finished pulling and reseating the crossover tubes and that helped a bunch. Easier to start after warm and runs with more power. Now I've had one time where the grid heater popped on with 10 chimes. Pulled over and pulled out the OBDII tool there were no codes and the grid heater light went off on its own. Now if I turn the engine off and reconnect to the CANBus I can clear the codes that don't exist and the grid heater light goes off. Nevertheless, the little work to get the crossover tubes retorqued and checked I do have a few tubes that might have some damage causing the hard starts. Hence why I posted the thread size of the crossover tube. 14mm x 1.5mm. When I can buy 2 crossover tubes so I can replace the questionable ones.

-

2006 Dodge Ram 3500 - Thor Project