Everything posted by Mopar1973Man

-

6.7L 200 degree thermostat - Experimental Idea

Doing all I can with Beast with all my medical appointments and most of them being in Boise ID. With even today it was a bit more than a 1/4 tank to get home but I had to school a flatlander how to run the canyon. Sure couldn't keep up with Beast.

-

6.7L 200 degree thermostat - Experimental Idea

-

6.7L 200 degree thermostat - Experimental Idea

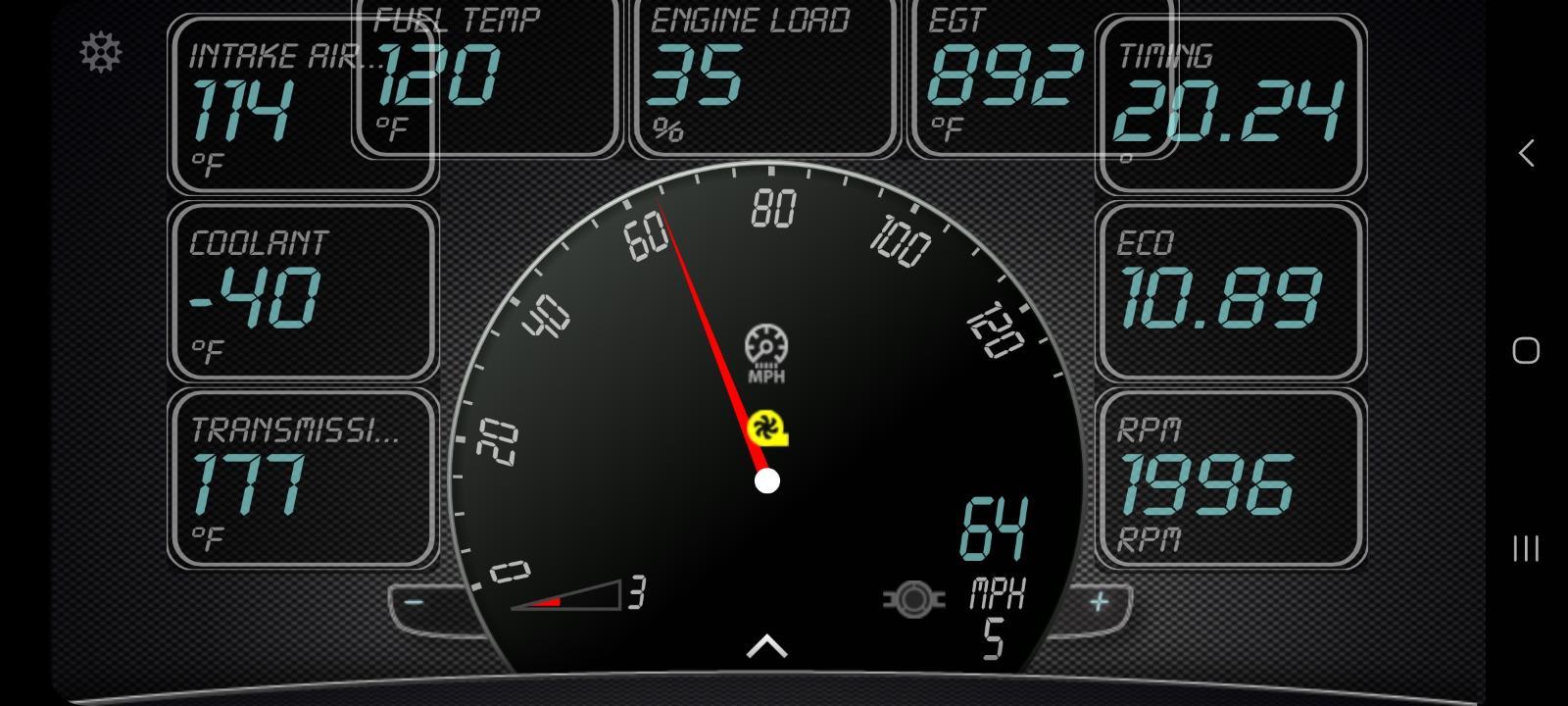

Another update. Still very controlled temperatures on Beast. We are hitting 90°F here and even climbing 7% grade it's still very controlled floating 200 to 208°F coolant temperatures and 170 to 175°F engine oil temperature. 100 to 110°F IAT temperarure. No updates to the Quadzilla tune being it still very wicked pulling a 25 MPH corner at 40 to 45 MPH and feel the rear tires break loose and keep powering the corner. Very sweet power even on level 3.

-

Pilothouse/RAM3500 build

I remember my 1976 Dodge Jamboree was a hot son of a ****** that would burn my foot on a long haul. Exhaust manifold with in inches of my throttle foot and the steel would cook my carpet. Yeah 360 CID V8 and running 3500 RPMs would create some heat. Ugh.

-

Pilothouse/RAM3500 build

Awesome. Looks really good. Lots of room. Still heat shield the pipe again for air space too.

-

Runs rough, stalls, dies, fault code P0320

Again a bit more

-

Runs rough, stalls, dies, fault code P0320

This explains it a bit more...

-

2002 motor swap

Better read again... Just replaced a photo that is missing... As you can see the cam has to be swapped and so does the gear case to get the engine swap done.

-

2002 motor swap

Your going to want to read the article about this. https://mopar1973man.com/cummins/articles.html/24-valve-2nd-generation_50/51_engine/swapping-vp44-cummins-engine-between-985-00-01-02-r429/?do=getLastComment&d=4&id=429 I know the text is dark. I'll try and fix it.

-

6.7L 200 degree thermostat - Experimental Idea

I'd be happier without the bags. Either way I get up every morning and do what I can do like yesterday got two other guys Einar and Mark to do the big work of getting my water fixed here for the yard. I did the pipe jointing. Today I'm going to be a bit lazy and rest and recharge it was a long day doing some basic work. PM sent.

-

Heat exchanger

I would say keep it and replace the damage heat exchanger for the transmission.

-

My Personal Opinion

My adventure continues... I'm still doing makeup and enjoying life the best I can with my cancer and my two bags hanging off my back. Seems quite amazing to see how many people stop to give me comments and props for what I'm doing. I'm still working on my own style and look with what I've got. Like most say, "Fake it till you make it". I need to replace my choker collar being the strap is ready to break. Even when I'm hanging out with friends I get people stopping me and commenting on my looks. Donnelly Idaho (Stinker Station) - Erica was the one to shoot the photo here... Like here I was on my way to drop Erica off back at her place in Donnelly ID. We stopped at the local Stinker Station and these two women commented on my looks and since they said something I always asked if I could get a photo with them to add to my TikTok account. Lewiston Idaho (WinCo Foods) My monthly shopping trip I went alone and opted for my Black and Purple hair and like typical its a women favorite. I was standing in the soda pop alise and these two women spotted me and commented on how bright the purple color is my hair and asked if it was aa wig or my actual hair. I told them it was a wig and I'm fighting cancer. So the gal with the green hair shot the photo but it was aa fun time in WinCo. Clarkston, Washington (Walmart) This gal I felt sorry for. Look at the lower right corner you can see her cane. She was chasing me all around Walmart trying to catch up with me. I just left the automotive area grabbing two batteries for my Jayco trailer and thought I needed to get makeup wipes for cleaning makeup off my face. She cornered me in the makeup area and gave me a stellar comment. "You are F_cking Gorgeous! " She was impressed by my looks and will be looking for me next time I go shopping too.

-

6.7L 200 degree thermostat - Experimental Idea

Yeah Mark and I stayed here along the Salmon River for 5 days. As for the Quadzilla tune, I will say my timing is the same but I zeroed out my cruise timing and disabled that knowing I rarely can reach the cruise state and I can't move the cruise state higher in engine load without possibly blowing the head gasket. Then for the retard settings you need to retard pretty much fully to get the spool you need for pulling grades and climbing with weight. I know I can hold WOT and have no issues with EGTs on level 3 as usual. Engine oil temperature remain in the 170's and coolant was still normal. EGT's I have been under control. As for me and my cancer, I spent those 5 days just relaxing, eating, and enjoying some quiet time without my cellphone and internet. I will do this as much as I can as I heal from my coming surgery and even before if I can squeeze one more trip in. Now notice I'm running more retarded timing and my EGT's are still in check. I know you can't see boost here but I'm still below my 15 PSI break point for adding fuel. Even now I'm only using the 150 HP injectors but no added fuel by the Quadzilla. No smoke issues and temperatures across the board are still under control. Cooant, Engine Oil, EGT's, etc. All stable and not ramping up even scaled out at 17,500 pounds with the RV fully loaded with water, food and supplies for 5 days.

-

Electrical problem I think

First thing. Replace both batteries with new batteries. Then might be a good idea to do the W-T ground wire mod. Also have your alternator tested for AC noise. Weak batteries can cause all kinds of issues.

-

6.7L 200 degree thermostat - Experimental Idea

Update... I produced a towing tune and took off for a 5 day camp trip down near Fiddle Creek which is just south of Lucile ID. I can say I hit proper timing in the first try and oil temperature where still 175 to 178°F and coolant ran like usual around 204 to 208°F no problem. I was seeing 12 to 14 MPG flat ground travel. No issues to report even towing. I'll post up my towing tune here shortly. I'm still running around haven't been home much more than few hours and left again.

-

Auxilary tank install, anyone have one????

Look up dual tank control valves. You should be able to get either a manual or electromechanical valve for controlling fuel on a stock set up. Now AirDog / FASS is tougher with 1/2 inch lines. Just consider gravity setups it's possible to over fill if you forget to shut the valve.

-

Fog lights on randomly

Could be a bad switch or the ground side of the bulb lead is shorting to ground.

-

Aux Lighting and Negative Switching Advice

Keep in mind that like the headlights you can blow a fuse and get back feed and still have a lit bulb.

-

6.7L 200 degree thermostat - Experimental Idea

-

1999 24v cummins changes engine tone while keeping steady speed on highway

No. It typically dries up before it hots the ground. Like mine did it only leaked and puddled on the floor with a coolant system tester. Normal driving it would have the smell but nothing on the ground.

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Simple test. On a cold engine hook up a coolant tester pump it up to 16 to 18 PSI and wait. If it's leaking out a puddle should form on the floor as pressure drops. Be aware my first head gasket blew out in the rear of the head due to weak head bolts and head curl which is normal around 300k miles.

-

1999 24v cummins changes engine tone while keeping steady speed on highway

Cummins CanBus is limited because of the Cummins ECM software bug. Now Dodge CCD network over the OBDII port will show correct because the software does not have that bug. Yes any OBDII live data tool shows correct values but sadly Quadzilla never show any temperature above 204°F.

-

6.7L 200 degree thermostat - Experimental Idea

Starting back in the beginning of 2023 winter I opted to play with 200 degree Cummins thermostat from a 6.7L Cummins. Now as winter got to the coldest of minus 7 degrees I was happy to keep a warm cab and engine. I watched over the winter time and as I was able to keep temps above 80 degrees in the intake manifold (IAT) I noticed an improvement in MPGs because cold air does rob the engine of ignition quality and more heat energy is not wasted to the coolant jacket. Now fast forward to now. I made a trip to Lewiston ID for monthly supplies and food. Still running a 200 degree thermostat in 90 degree weather. This is a Gates Thermostat and seems to hold steady between 200 and 210 degrees of coolant. Even climbing 7% grades everything still running normal specs and no issues. I'm happy to say MPG wise I didn't quite use a 1/4 tank more like 3/16 of a tank in a one way pass from home to Lewiston ID. Level ground EGT's are still cool. Engine oil temperature barely touched 178 degrees even climbing long 7% grades. Boost was between 10 and 13 PSI. Flat ground cruise

-

1999 24v cummins changes engine tone while keeping steady speed on highway

I'll tip 210°F at 80 MPH. Typically at 65 MPH is floating at 205°F. No, there is no way to fix because it a Cummins software bug in the ECM. A live data tool will see full range of coolant temperature.

-

Questions..

Food for thought. 150HP injectors and tow on a stock HX35W turbo. For sure need a Quadzilla to control timing and EGTs.

.jpg.c373210f35563bc9cb56f53c7dd894e4.jpg)