Everything posted by Dieselfuture

-

Top hat valve seal and valve train

Just got off the phone with local shop, they now said to use PIONEER T-51444 for valve seals when applicable. So I got a 50ml bottle coming, not cheap ether. I hope this will do it with regular seals, so I don't have to make a mess grinding. I told them I was going to use a whole saw ant slip it over guide and grind that lip off, they said I was nuts and should bring the head in for machining, I said if I would of know last summer I would of had them do it then, 80 bucks, no brainer really. And they do use top hat, they must of been too busy to mention it last time idk. They also do buy a bunch of stuff from Manton and the usseals. He said he doesn't want me to use this PIONEER T-51444 because it will be a bic.. getting them off next time, I said good because it will be you who have to pry them off next time I bring the head in I guess we'll see if this crap works, I really don't want to use a whole saw and dremol, or do I

-

Top hat valve seal and valve train

Yes and funny thing was he said I'm first who's asking him that lol, he's basically said I shouldn't have a problem with his regular seals that i listed above as they are better and if fitment is good no need to worry. I explained the whole deal on these heads and how they are smooth with no grove for seal to grab on to and that I can't use top hat seals because of a lip that seal rests on, that lip needs to be machined off for top hat to sit flat on bottom. Then I asked if he could make me some seals if I gave him dimensions, he said yes but then said I'll need to get at least 15000 so he can make a die. Well I'm not about to open a shop to sell seals, which I thought would be in demand on our heads. So if we can get someone like dap call him and place an order, anything is possible. I think he said cost will be around. 30 some cents a piece at that quantity, so even if you sold them for $2 a piece to eliminate this problem, you'd still be making good money. And I know right now I would pay $5 for top hat seal that would fit without machine work.

-

EMF Ball Joints?

Man 5 dollar ball joints may be where it's at, never know

-

Bumpers any advice

I ran across that one on YouTube a while back man some people, Wonder maybe she was just playing a joke too

-

Rattlesnake Fire, Idaho - 2018

when my back hurts from a bad disk and I become useless, I can't help but wonder thinking back in time how I screwed it up and for what reasons, then all I could think afterwards is what an idiot. Maybe that's why they say life is a lesson you learn it when you're through. you would think after few rain events when they actually get there it wouldn't matter, and nature will always heal itself.

-

Smoke on start up runs rough for a bit smells like oil

Ok another update, I started another thread and probably will be posting there the end results. So it's a common problem to have freshly put on exhaust valve seals to come up, there seem to be more then one reason why. Best thing to do is to machine head to accept Top Hat style seals. I ended up ordering a bunch of stuff from Manton, super nice people very knowledgeable and gave me an awesome package deal. I'm going to see if I can machine the head myself to accept Top Hat seals, if not I will be using regular seals with maybe some adhesive to keep them on. Here is my other thread.

-

Weird issue with brake pedal feel and PS pump

I'm pretty sure the problem is related, somehow air got in system. Maybe after your trip something got hot enough to do that. I'd blame it on your turbo blanket didn't you say you smelled something like oil at one point when climbing steep grade, could have been something to do with it. Sorry not trying to miss guide you or anything, just some random thoughts.

-

Top hat valve seal and valve train

Yes sir, I've been reading up on it but nothing set in stone yet. Loctite 680, 518, bla bla bla trying to find something that will work metal to rubber (viton) You guys should really check out this place for all your seals needs. https://ussealparts.com VS-C59AV intake VS-C59BV exhaust VS-C59LV later model top hat is might have intake and exhaust backwards but you'll need 12 of each, I got 14 just in case.

-

Top hat valve seal and valve train

I knew someone would mention it lol. But seriously need something to keep them in place and something that doesn't cause damage to engine later if it ever got hard and got out.

-

Free Legal MP3 Music

Sweetie please click on the blue allow button

-

Top hat valve seal and valve train

That seems to be a common problem. My take on this is when truck was new it was used as intended with 20psi of boost for a long time everything had time to wear in place. So with time gap between seal and valve stem got looser and by the time dumb kids got a hold of it and put injectors and turbos and tuners on, seal had enough blow by and it didn't work it's way up to get smashed by retainers. Idk I'm just guessing, but it had to be a problem and people started to use top hat seals. This goes for trunions too newer trucks have an oil gally to prevent scoring on roker and trunion. Same with roker bridges on newer stuff they are stiffened with webbing and not just stamped. So for now the question remains on what monkey glue we need to use to get away with regular seals.

-

Top hat valve seal and valve train

Has anyone used or know of a good loctite that can bond Vinton and metal for high heat. I'm probably going to try using something to keep new seals from poping up. My new seals will be made from Vinton and head is cast, I'll clean it up really good and hope for the best. Edit, Has anyone used loctite 266 http://www.loctite.co.uk/loctite-4087.htm?nodeid=8803867197441

-

Top hat valve seal and valve train

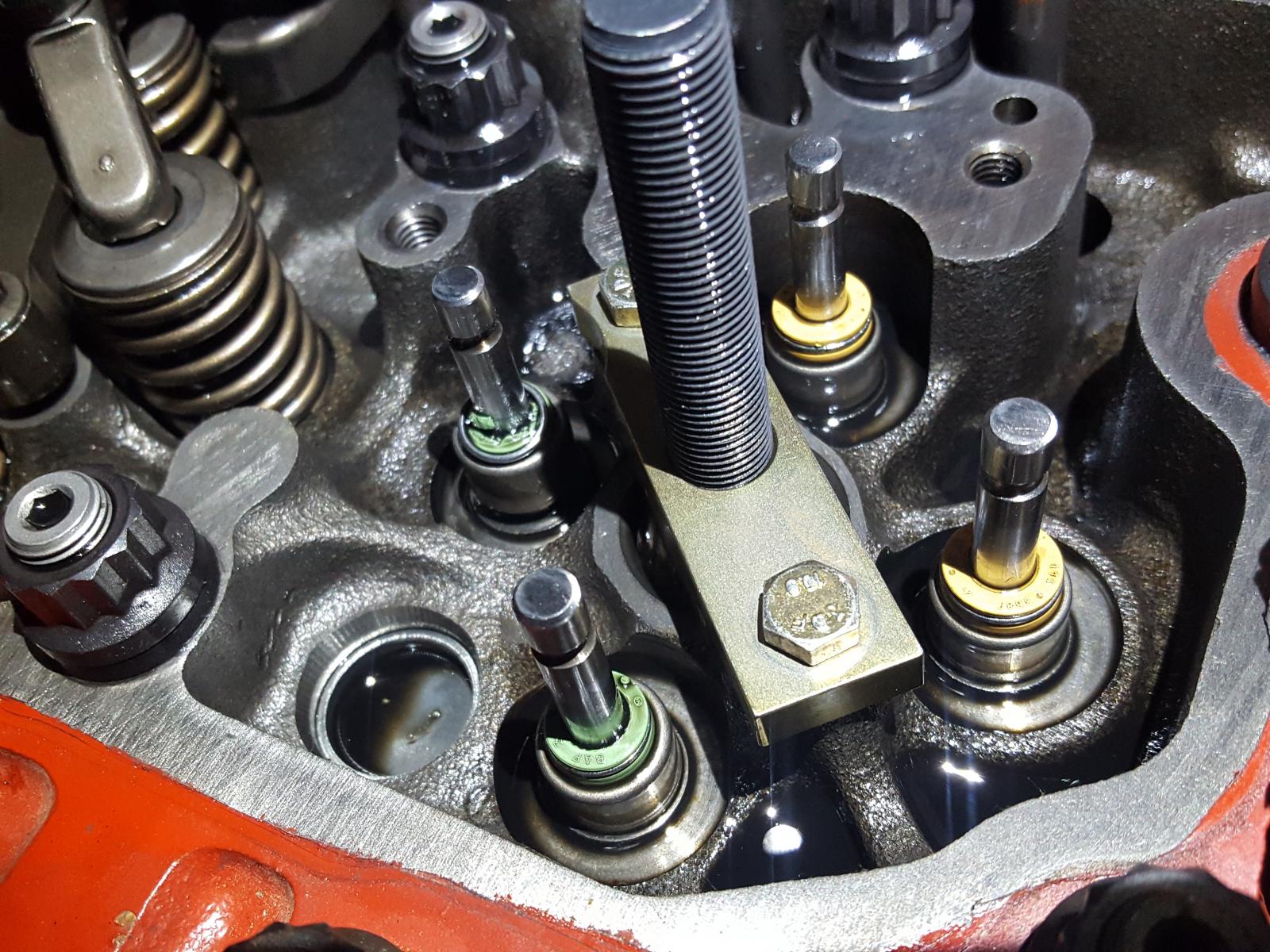

That's a picture of a 12v I found on line to show seals here is mine. You can see trunion getting bit up too. So the shop is saying I can remove spring of new a seal so it doesn't grab valve so hard. Yes I thought about cutting a groove in a guide so seal can slip over it or use some superglue lol

-

Top hat valve seal and valve train

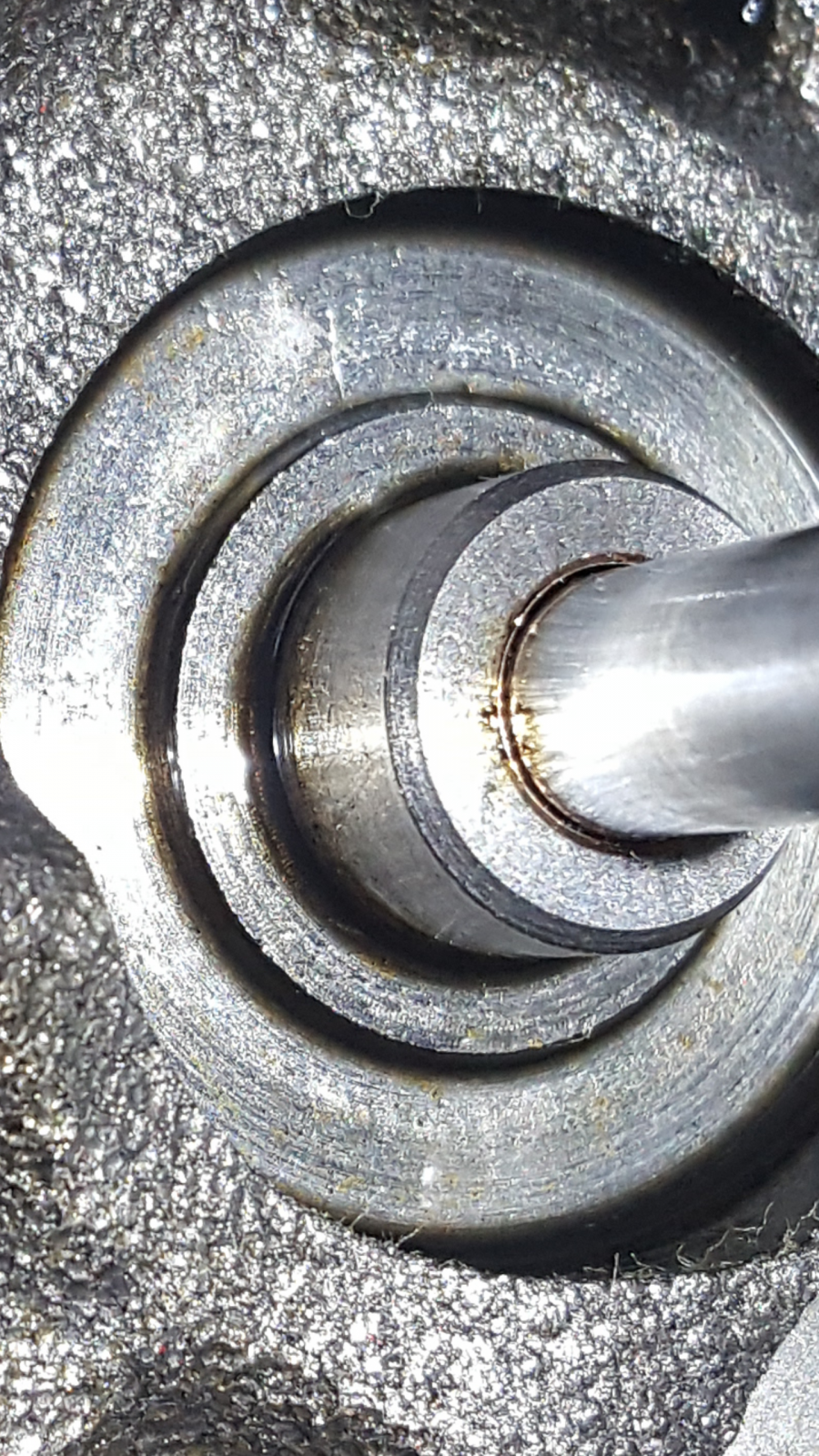

Here is a picture, regular seal on top and top hat on bottom. Red arrow is pointing at the lip that needs machined off

-

Top hat valve seal and valve train

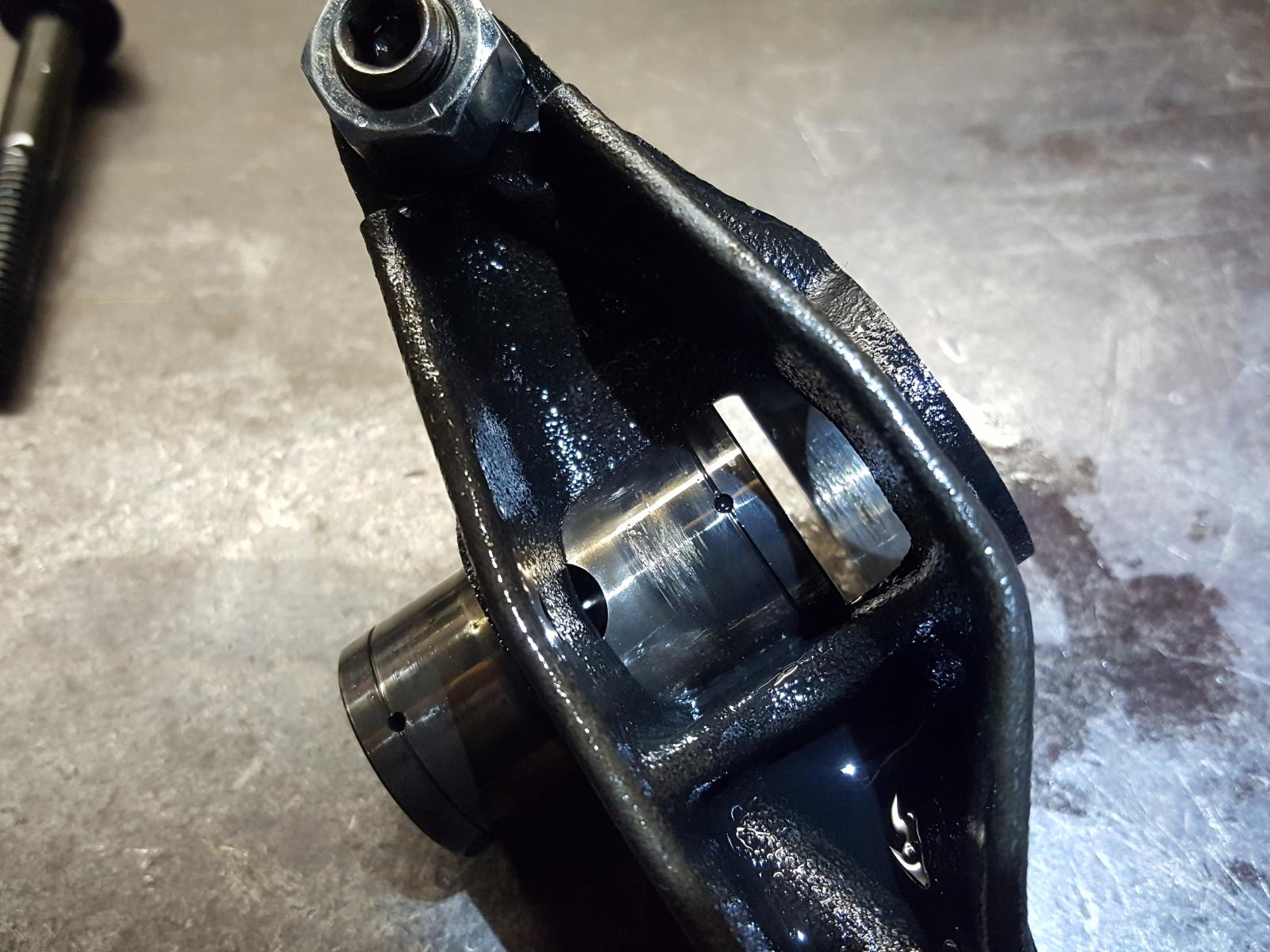

I think we're on same page, yes some of my exhaust seals walked up 1/8" from being pressed to bottom of guide. last summer I had new sleeves put in inside valve guides as some of mine were ovaled out. From what I understand coming from (Manton tech) he said it could of been caused by bridges flexing, so I might be getting new bridges, trunions, pushrods, valve springs to stiffen things up. He said it becomes important when turning more rpm and using more boost (especially when towing heavy), because everthing is vibrating from frequencies and etc. I know I probably don't need this extreme duty stuff, but I also don't want to wish later that I should of done it. My trunions are getting galled up and so are rockers according to him it's because they are made from same material and also missing an oil gally in a critical spot, newer models started to put that galley in to minimize this problem, some people cut their own grooves. Push rods he recommended 1/2" as he said bigger the better keeps them from flexing, I know 7/16 is plenty big but why not. The springs they use are conical shape so that at full compression it's not over presurising cam/tappet where he stated quite a few sellers have way to much pressure when spring is pushed down and chewing up cams. Here is their website. http://mantonpushrods.com Sorry for the rant, seems like it never ends with us gearheads just when you think you got something you have to renovate again. I guess biggest issue at this point is seals that are getting destroyed, then everything else. Are you using top hat without machining the lip of the head? And how do yours fail, get tore or wear out. I hope this thread gets someplace lol. I was thinking of using umbrella type seals like on older trucks, but I think oil puddles up to much where seal is and may be making down the stem to easy. I'm in a brain storming mode right now lol. Still think the solution is to machine the lip off and use top hat seals. Or talk with seal manufacturer and see if they can be nice to us 2nd gen guys and make a top hat that fits over the lip. I like this idea better.

-

Bipolar HVAC fan.

Thanks for the thread, I've had minor issues with mine, ordered new blower and resistor from Rock Auto

-

Boost Leak Tester

Use a good clamp, cheap hose clamp may blow off

-

Dyno numbers

We're you asking me or OP, I started a thread about mine, been an adventure so far. Wish I would of researched it last summer when I had the head off. Didn't think it was an issue on mighty Cummins, apparently it has as many issues as any other motor. If i would of known I'd have them machine seats to accept top hat seals, now I might be grinding it myself. Don't really feel like taking head off again.

-

Top hat valve seal and valve train

@04Mach1 do you have any input on seals and why they work up from being pressed down and get hammered by retainers. Have you dealt with both styles, top hat and regular.

-

Top hat valve seal and valve train

Yes apparently it's a common issue for some to have new seals work their way up and get hammered by retainers. I wonder if they can be glued in place

-

Top hat valve seal and valve train

I'm now finding out that top hat need a lip removed from the head to sit down properly I might be using a dremel here because no way I waiting on new seals to pop out again. I have to wait and see what they look like first.

-

Smoke on start up runs rough for a bit smells like oil

Here we go. Trunion is galled up a bit so it won't be getting better. I was told I can clean up roker with scotchbright and reuse it with new trunion from Manton. They said it's a common problem especially if you go heavier springs and bigger cam, we'll mine just like to wear just because. Seals that were ripped were popped up about 1/8 of the seat, something pulled them up don't know what yet. Intakes look good but will be changed anyway.

-

Top hat valve seal and valve train

These ford seals may or may not work with sertain valve springs, be sure to measure all Id/od before committing. So I'm in process of figuring out why some of my seals are tore/smashed. Finding out that new style seals 03 and up may work on our 2nd gen. They are held in place by spring and can't come up from too much boost etc. I've spoken with https://ussealparts.com and they have both styles at great prices, although top hat style is listed for 03 and newer. The difference I believe is in ID where it slides over guide, sounds like top hat is slightly bigger but that should not affect the sealing capabilities as valve still same diameter. I ordered both styles and let ya all know. Now this place advertising them as they do fit. https://puredieselpower.com/dodge-products/dodge-6b-cummins-intake-valve-seal-exhaust-valve-seal-set-b45962-b45963.html#/product/21380 Another thing I might be doing is upgrading to better push rods, springs, trunion bearings and roker arm bridges from Manton. That may explain my ovaled guides and smashed seals, or so I hope. Let me know your thoughts

-

Smoke on start up runs rough for a bit smells like oil

Thanks for the info, I'm not too fuzzy right now lol. Waiting on dap to give me some pricing and spoke with Trevor at Menton, nice guy and gave me lots of info and better price. So I'm going to disassemble my head and see what's all screwed up. Sounds like my previously ovaled guides could of been due to weak springs and rocker arm bridges. Also trunion on roker arm can go bad, so now I'm debating on how much I want to spend and make it right. I just don't see the end....

-

Smoke on start up runs rough for a bit smells like oil

I talked to machine shop and they said that more than likely I floated valves or valve lash was to tight. Told me to get it apart and see if anything moved. Anyone else here turning 3000+rpm with stock valve train? I know quadzilla is set to 3200 and on ocasion I get there. Also they have used top hat seals before and they are interchangeable from intake to exhaust, but adds .020 to spring hight and little more tension. @jlbayes are you out there, can you put in your please to this post.