Everything posted by PilotHouse2500

-

Pilothouse/RAM3500 build

come January when I hope to pull the '94 in the shop to start the tear down, ALL parts not on the power train are available for the asking. PM me if you are looking for any parts before they head to the landfill or scrapper.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

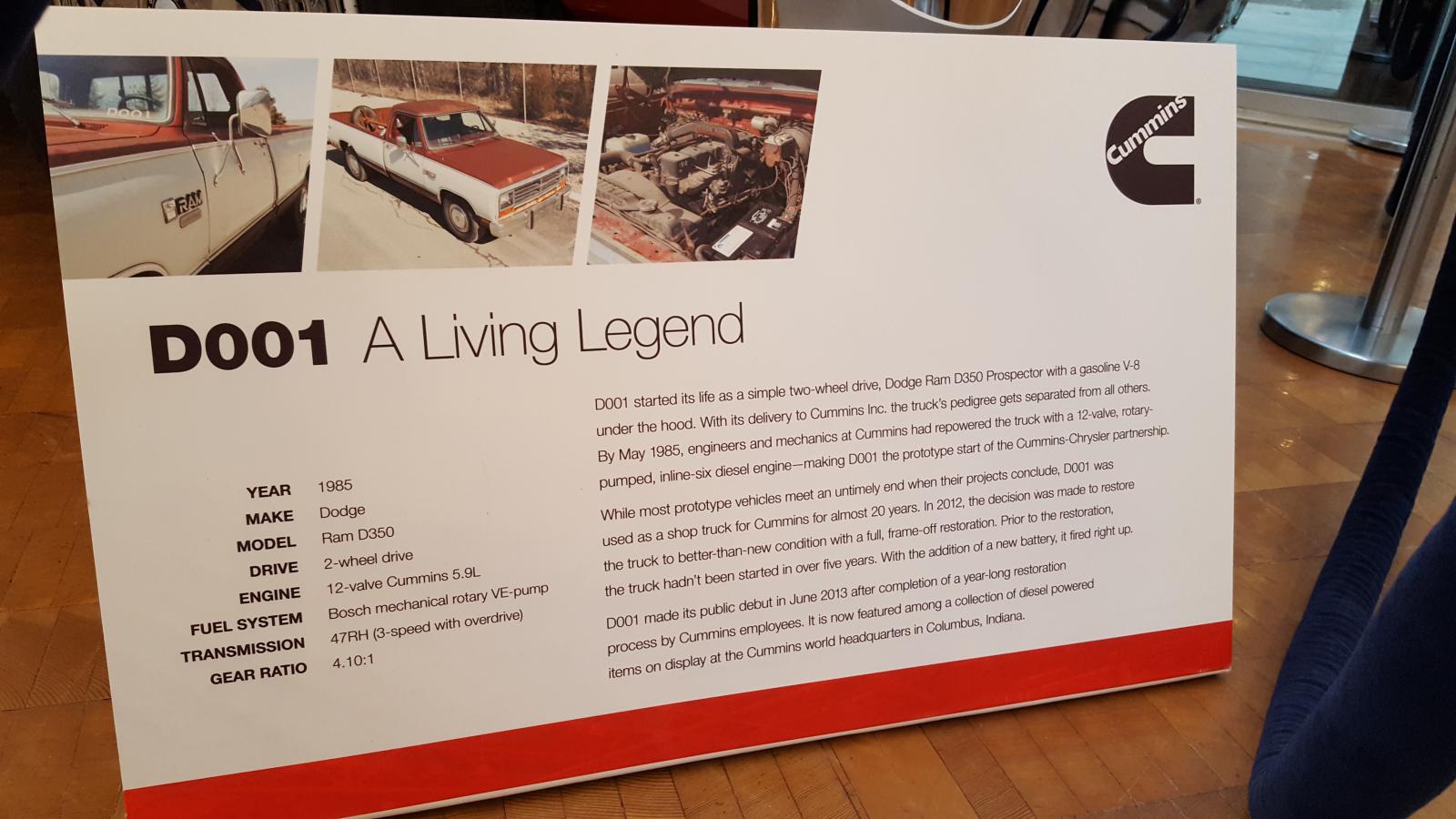

Well, I'm back in business, a few wood projects to finish up I contracted for while between positions, but I started my new job 2 weeks ago.....at Cummins! I'm in Power Gen systems (diesel gensets), but I'm now part of a great company, with cool products! I hope to get back on the truck here in January.

-

Pilothouse/RAM3500 build

still working on the project, but it is on hold. My position was eliminated at work and I'm on the hunt for work and doing a lot of woodworking to help pay bills right now instead of playing truck.

-

Pilothouse/RAM3500 build

Well I THINK I got all the pictures replaced. Let me know if something looks broken.

-

Pilothouse/RAM3500 build

I will find SOMETHING. Somehow. I post on 3 different forums on this project and it was super easy to use photobucket. Simple math with assumptions puts the money grab at $400 MILLION! It's a LOT of pictures to find and repost/posts to edit! No worries I'll keep them coming...somehow all about getting it appraised...likely would not truly cover a replacement, but better than nothing I guess. When I'm done, I'm sure I'll have over 40K into it, not including my time. Likely appraised to maybe 10K over that. Lots of custom rods are done this way...but unless you are a Foose or some other big name you don't ever get the REAL value in an appraisal.

-

Pilothouse/RAM3500 build

photobucket's new ransom to 3rd party posting will likely mean all my pictures will be going away. I will see if I can reload them at some point...

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Top center secion all done. Hammer and dolly work and grinding complete. Sides formed and tack welded on. Finish welding those up and then onto the firewall and floor replacement!

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

Neighbor runs a car shop and had graciously offered to help for free (beer and food) to help me out over the course of the summer while at the bonfire...well he seems to want to get it done because he's been on my case! Last night he taught me some BASICS of the English Wheel! First pass shown here. A little more crown to add in the middle but close!

-

Pilothouse/RAM3500 build

templates made for the roof section...hoping to have that finished off and pictures posted in Feb!

-

Pilothouse/RAM3500 build

no I haven't died, no the project is not dead either....the project will start up again in January, life has just gotten in the way with job change, tractor repairs, 4 wheeler purchases, property maintenance and tree planting. More as soon as I can!

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

it will be a daily driver, so chances are when finihsed I'll drive to a few shows outside of MN where I only go now with my 50mph restoration.

-

Pilothouse/RAM3500 build

thanks! I got the body panel clamps off Amazon (they are Harbor Freight parts) and the "C" clamps at the welding supply store (they sure are nice).

-

Pilothouse/RAM3500 build

this weekend's work. I took apart the window top part so I can keep the seam by rewelding it all back together in the order it was first assembled. Please note the welding wasn't done when I took the last 2 pictures.

-

Pilothouse/RAM3500 build

yes it is. I think I may have gotten impatient in a few spots, I did end up with some warping that I'll have to deal with.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

I might have a problem... not a diesel (yet)...but I acquired another truck...saved from the crusher.... https://www.dropbox.com/sh/3hv86432yqhontx/AAD1qBzivRBGUq4-7F82BcAVa?dl=0

-

Pilothouse/RAM3500 build

The shop came "as is" from the previous owner. He repaired exotica (he had a Ferrari) for his business he ran out of the shop. The rear (where my wood shop lives right now) is bare concrete. He used that area as vehicles storage. I found out last night just how dusty wood working will be in there...need to get on better dust collection for my table saw (HUGE contributor to dust last night)! Or every so often I will have to get the leaf blower out and blow the place out!

-

Pilothouse/RAM3500 build

things have been slow as I sold my old house and moved to a new location, but I've gotten all my toys to my new place and got some decoratin' done! some more shop pictures: For now I'm putting my wood shop in the back of the vehicle shop. https://www.dropbox.com/sh/8oivc81863ec3m1/AACTzqUpyf95jM0AmJs8-Ut_a?dl=0

-

Pilothouse/RAM3500 build

lots of English wheel work and LOTS of tack welding the pieces back together so there is little heat deflection at the joint.

-

Pilothouse/RAM3500 build

.jpg.ca5e7327a684cfb2904efbfde32f079a.jpg)

.jpg.d97d4371aabaf3bf0e520e89ef0407b7.jpg)

.jpg.7bd5a41b3c683bb576c96f66301e9415.jpg)

.jpg.75de8890d064bc5f779f5030feaa8722.jpg)

.jpg.ab7456344151d9d4dcab5fd130d6c936.jpg)

.jpg.2e7f4e169af4b6a3a9a5fac8f3584d81.jpg)

.jpg.4b68deed64141cfa6e9d410c609ceb90.jpg)