Everything posted by PilotHouse2500

-

BARRING tool

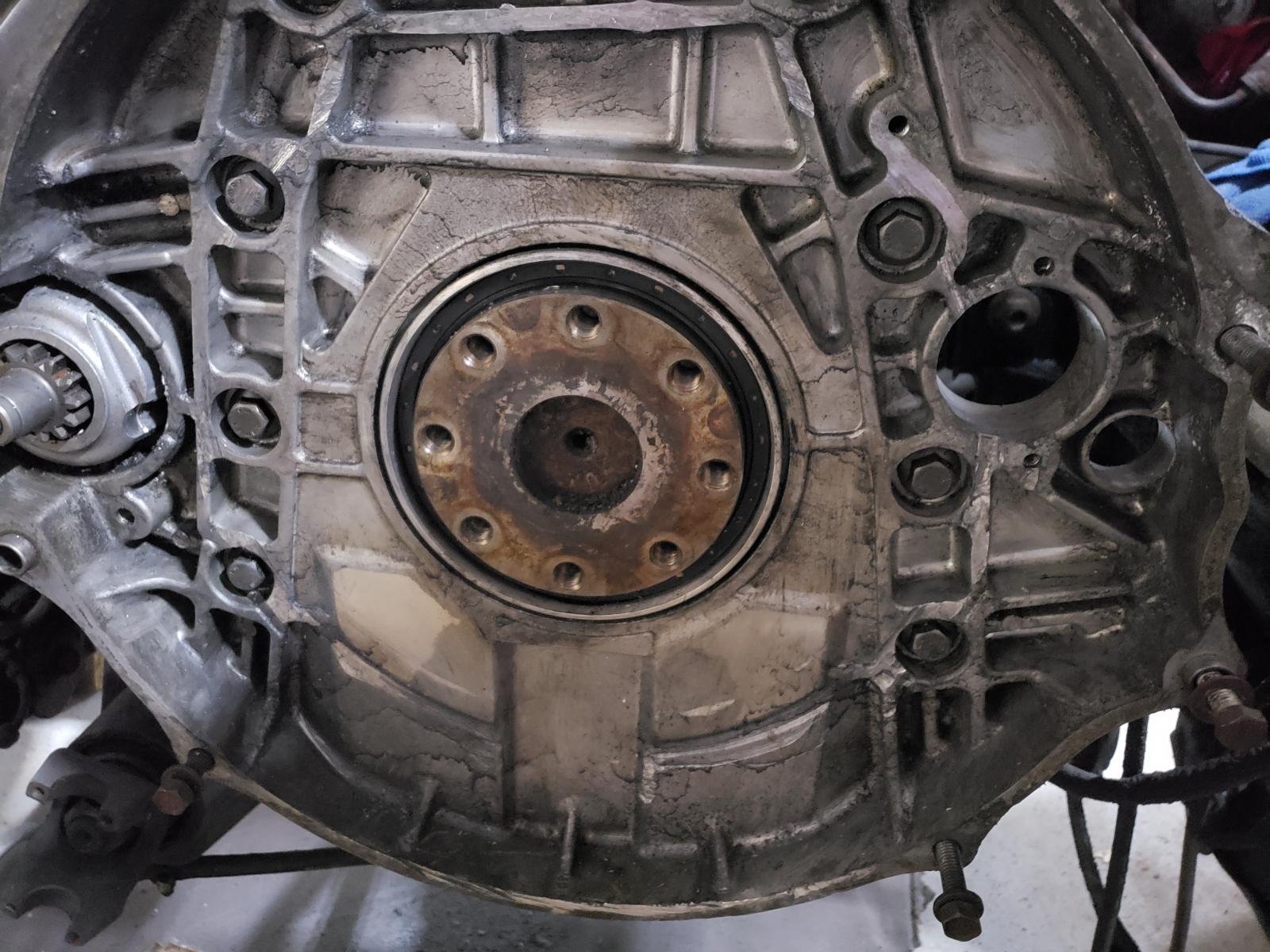

Spent sometime last night messing around with things. I got a barring tool from the lead tech out in the engineering tech center and it is of much higher quality. Putting it opposite the one I bought, the only difference is the length of engagement. So I scratched my head and compared the old ring gear with the new one. Again, same size. Ok I bolt up the old one (without the TC attached), and see where things land. Both tools land nicely on the ring gear....so ok, lets try to use them...both tend to want to pull off the ring gear if I don't put some force towards trying to keep them engaged. Doesn't seem right to have to put THAT much load on to do that, but it did work, just tool lots of time to advance very far. So I poked around some more and it seems that whomever fixed the issue below (see the areas where you can see it's been worn) obbed out the hole for the tool, allowing the tool to move more than it should. Seems the PO (NOW he tells me) that the reason he had the trans rebuilt was the flex plate was loose that did all that wearing (and now I know where all the metal chips I found were from). I guess even buying from someone you know very well, you end up with surprises.

-

BARRING tool

I don't think it's an issue of spacing from the block. The tool seated and lined up with the teeth properly (depth-wise), but was too far away to mesh (horizontally). So either the barring tool is the wrong diameter, or the ring gear is different. I had read reviews that engagement was the biggest issue with these tools and they'd just skip (like this one did), but this one was said to be a solid match.

-

Pilothouse/RAM3500 build

-

BARRING tool

tonight I will literally lay the old ring gear on the manual ring gear and see if there is a difference. If there is a difference the starter would need to be different as well and I don't see that as very logical.

-

BARRING tool

well that didn't work worth crap. I could see it not engage the ring gear teeth, it just skipped off them. NO reason that I can think of that this shouldn't work between and auto and manual trans ring gear.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

BARRING tool

cool that is the one I linked from Amazon.

-

BARRING tool

Looking to pick up a good barring tool to work on my 12 valve. Reading reviews just frustrates me and I don't want to waste $40 on cheap junk. Who is the vendor of your choice for this essential tool? Two I was looking at: https://www.amazon.com/gp/cart/view.html?ref_=nav_cart https://www.genosgarage.com/product/tool-ltbt/tools

-

Pilothouse/RAM3500 build

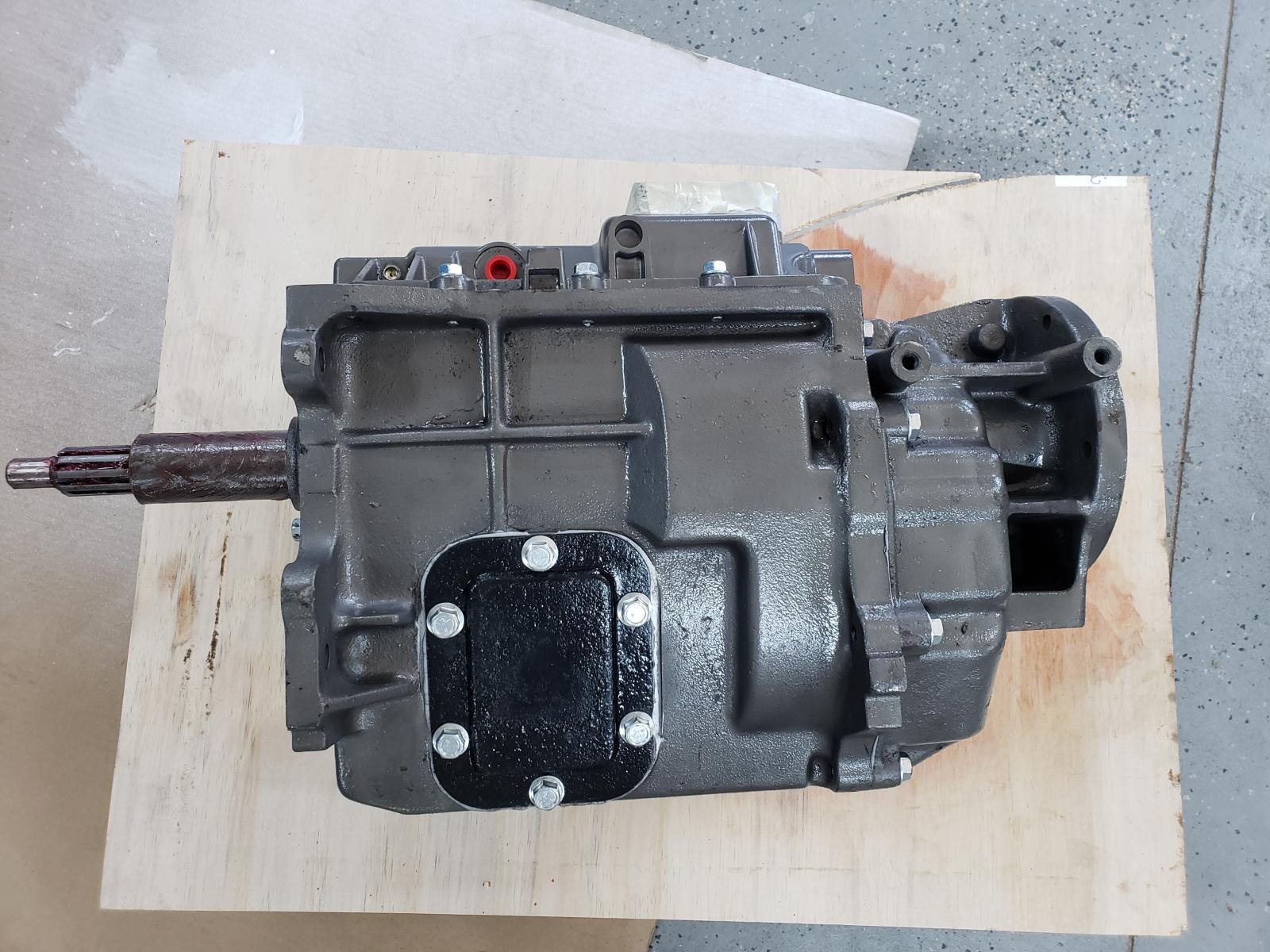

On Friday I ordered the NV4500 tans! 2-3 weeks for delivery....sadly they don't take an auto as a core anymore. So now I have an auto with under 10k miles on a rebuild, but no documentation since my buddies wife tossed all the paperwork on the rebuild years ago...sigh..

-

Pilothouse/RAM3500 build

G56 off the table, NV4500 is the choice. Now to get the "extreme" version or the standard?

-

Pilothouse/RAM3500 build

Money comes in Saturday! Salivating over the trans swap coming! Any final thoughts (prayers accepted) on this? Still kinda debating the G56 vs the NV4500 swap, but cost might drive me to the NV4500 regardless.

-

Pilothouse/RAM3500 build

Good news is I've decided on a few things and I'm in the midst of a huge kitchen project that will actually let me get the trans bought. I'll be moving the engine back 2-3" to use the stock CAC and buying an aftermarket RAD with electric fans to get things stuffed up front where they belong. I also plan on taking the summer off woodworking so I can get some headway going on this project. SO hopefully come mid May this thread will get more updates than it has in the last year.

-

To CAC ot not CAC that is the question

Think I have decided to push the engine back 2" to keep things relatively easy. New motor mounts and such are a lot less fiddling around then dealing with creating all new plumbing.

-

12 valve 6bt trans swap to G56?

Getting the money together to finally get the manual trans for the project. I know a NV4500 is a pretty easy swap out as it was stock, and I've been in contacts with high-impact.net for the parts. I know the NV5600 entails a bit more of a challenge (a poster had a link to a thread of someone else's swap) so that CAN be done. But I was wondering if anyone has grafted a G56 to a 12 valve 6bt?

-

Pilothouse/RAM3500 build

sitting on the racking outside the shop waiting for you to pick it up!

-

1948 Dodge COE Build

oops Oregon not Washington, still want to see if I can hook you two up?

-

To CAC ot not CAC that is the question

Actually had to cut the frame off to make things fit w/in the front clip of the 50's body. I have to center the wheels on the fenders and that drives where things land. Moving axles and such would be a little to invasive for my level of comfort for a daily driver. Thanks for the inputs. I'm leaning towards leaving the engine where it sits (simplifies a bunch: motor mounts, tanny x-member & mount, axle lengths, etc). I don't plan on pushing him too hard, but I think just going a cross over tube route might just bite me later so I think I'll do a CAC of some sort just in case. I've got room in the fenders to put something.

-

1948 Dodge COE Build

NICE project, I have a '51 COE after I finish my current build (likely a 6bt repower project). Do you happen to know a "Brent" in WA that is into the bigger old Dodge trucks? I'm sure you two would get along great.

-

To CAC ot not CAC that is the question

I'm progressing on my streetrod build and am running into space constraints with where the engine sits relative to the 1950's body. I know I CAN move the engine back with new engine and tranny mounts, but would prefer to not go that route. I've already decided to use a different RAD with electric fans in place of the stock fan for space, but need more if I want to not move the power plant. I've got 4" to work with. So a few questions for the great minds than mine leaving the power plant in place and having room for the RAD and AC condenser up front where they belong: 1. I could forego the stock CAC and do a liquid/air cooler and tuck that up under a fender. 2. Drop the CAC all together and just do a crossover tube. Thoughts please?

-

Morning Pic For Today...........Post A Pic around your place.....

-

Pilothouse/RAM3500 build

thanks. I've got a few plans that it will be near impossible to steal unless you tow it.

-

Pilothouse/RAM3500 build

After fighting and fighting to get the passenger door to line up right, I called the neighbor. He runs his own hot rod shop and has built MANY over the years. He's been kind enough to help me when I needed for nothing but a beer and a smile. I think he just likes helping me learn. Regardless, he came over and we chatted, and we tried, we got the torch out and bent hinges, and tried...and finally came to the conclusion below. I think he loved the pucker factor I had when I resigned myself to doing the cuts. Also we will likely work on flattening the top of the window to follow the now long flat section of the roof to make it look more pleasing.

-

Pilothouse/RAM3500 build

Extended cab. 1/2 size suicide rear doors.