Everything posted by PilotHouse2500

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

I plan a full rebuild and dyno of the engine before I really button things up, regardless the cab will be on and off several times yet.

-

Pilothouse/RAM3500 build

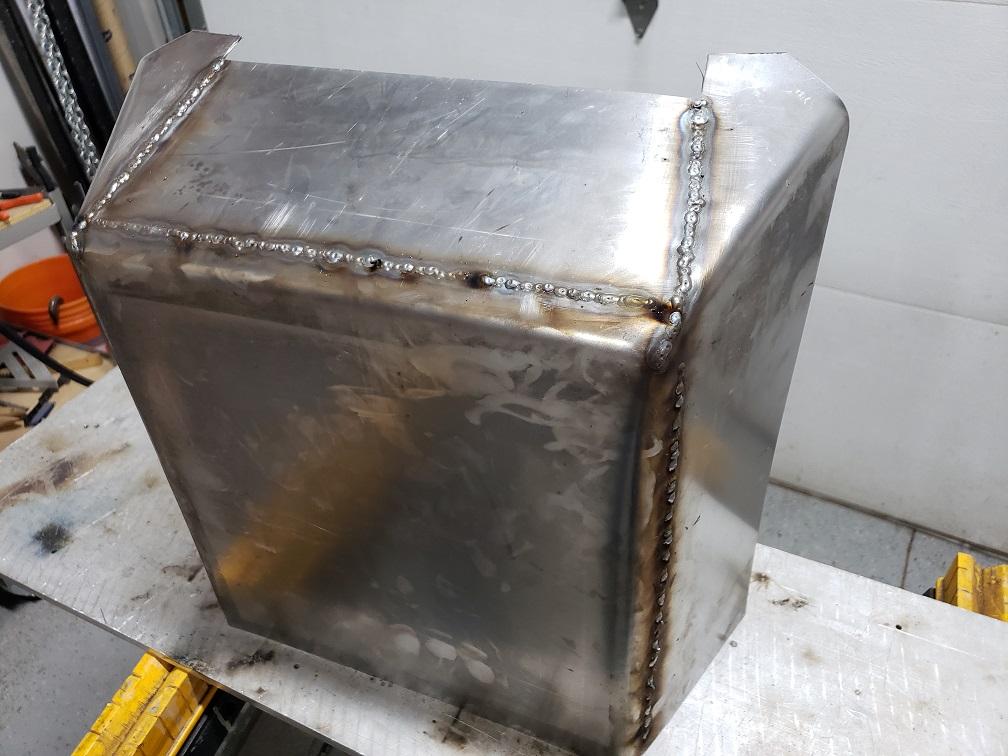

spent my weekend getting the requisite cuts on my fingers and stabs in as well...but I learned a few things this weekend: Minnesota sports had a good weekend (Wild win, Vikes win, Gopher hockey sweeps the Ugly Helmets, and Gopher football beat Penn to stay undefeated) My air shear handles 16ga no problem My electric nippers handles 16ga no problem My neighbor challenges me every step on this project to take it up one step better (more on that later when I can show a picture) Building a firewall is time consuming 4x8 16ga sheets are HEAVY and cantankerous.

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

-

Pilothouse/RAM3500 build

yah I have a small cabinet for parts you can hold in one hand. Way easier than a wire wheel!

-

Pilothouse/RAM3500 build

-

Pictures of trans mount

quick tape measure last night has both coming out to about 24" from the back of the bellhousing adapter to the mount studs. The cross member has slots, so it'd all be good...if I wasn't moving the engine! Which DOES make sense, altho several other things did change with the swap that could have been made the same.

-

Pictures of trans mount

I'll try to remember to take some measurements tonight to confirm. The swap website mentioned that you might have to move the crossmember when converting.

-

Pictures of trans mount

mount flipped, and shifter assembly ordered, thanks all! Back to an earlier post on the trans crossmember, I'd have to confirm via parts book, but I believe they are different between the auto and manual. The NV4500 is set up is different by a few inches, but since I need to shove the engine back 3 to 5 inches to fit the CAC/RAD in it won't matter as I'll have to fab up a new one.

-

Pictures of trans mount

thanks easy enough fix. Think I found a handle assembly on Epay....$75....erf

-

Pictures of trans mount

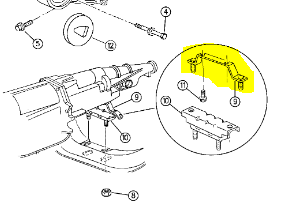

got the trans mount all installed. Was going to put on the TC shifter and well, it didn't fit! The auto had a stepped mount and the NV4500 has flush, so I figured I'd cut off the spacer and I'd be fine....nope...hole to hole distance is different. Looks also like it moved relative to the TC as well so I worry that the linkage will bind up if I fab a conversion bracket. I'd love to get the hole to hole distance from the bracket pivot point to the connecting rod pivot on the assembly. Reviewing the pics above I think I have the mount on 180?

-

Pilothouse/RAM3500 build

done for now, primed and painted...what's next on the list?

-

Pilothouse/RAM3500 build

TC and trans mated and sealed, tonight degrease and paint?

-

Parts (new and used) preferred suppliers

so thinking of keeping stock radiator in the truck but use electric fans...which source/brand do you consider the best? I find them at Autozone, Summit, etc. for about $125-650. Original leaks.

-

Pilothouse/RAM3500 build

progress from the weekend. Transfer case cleaned of grime and crud. Trans mounted to bellhousing. Not in current pictures: steel parts painted with POR15 (did that after the pics).

-

Pictures of trans mount

So, if I buy the one up above (and shown in the pictures from BBHD), I won't need the one below shown in the parts books as for "ALL MANUAL TRANS"?

-

Pictures of trans mount

awesome thanks! I have the rubber isolator but seems I still need the part I had up above to complete everything!

-

Pictures of trans mount

I've had the x-member in and out several times already, right now it gets put in from the top. This is why I was hoping for a some pics of what this all looks like. The mount doesn't seem to translate from the auto to the manual with the areas being vastly different where it mounts. I THINK the x-member is the same between the two (will have to dig thru the parts book more to see for sure)...if need be, I can make a new one no problem.

-

Parts (new and used) preferred suppliers

AWESOME! thanks gang!

-

Pilothouse/RAM3500 build

Watched a video yesterday of a guy doing a manual swap up in Canada. He mentions something about not using the vacuum lines (on the TC) and going to manual switch. Anyone here done that? meanwhile got the TC shifter taken apart and cleaned up...it was frozen solid. Nothing a 20 ton H press can't fix. And got to use my "new" media blast cabinet I bought from my car club friend.

-

Parts (new and used) preferred suppliers

yah, I know of RA. Will have to look for the carpart.com site. any others? thanks!

-

Pictures of trans mount

found this below. Does that look right? https://www.dodgeparts.com/1994-dodge-ram_2500-base-diesel_5.9_l_6-transmission_automatic_4-engine-engine_trans_mounting-rear_mount_upper_bracket_52019641-item/

-

Pictures of trans mount

I got spoiled on my 50's resto...parts books had really good visuals and exploded views of parts. I bought the parts books for the 94, but so far I haven't found what I'm looking for: Since I'm converting from auto to manual, I'd like a nice few pics of the trans rear mounting set up. Thanks in advance.

-

Parts (new and used) preferred suppliers

Started to tear into parts today, and I figured out why the transfer case wouldn't shift....shifter frozen solid w/ rust. So it brings up the question for me, who do you trust to deliver good new and or used parts? Not taking NAPA type stuff, but the odd stuff. I'm having a bit of a time finding a vendor. I have most of the PN's from my parts book, but searching with them isn't yielding much. Thanks!